Planetary gear transmission and wind power generation equipment with same

A technology of planetary gear transmission and planetary gear, which is applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of high cost and achieve the effect of increasing the tilt clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

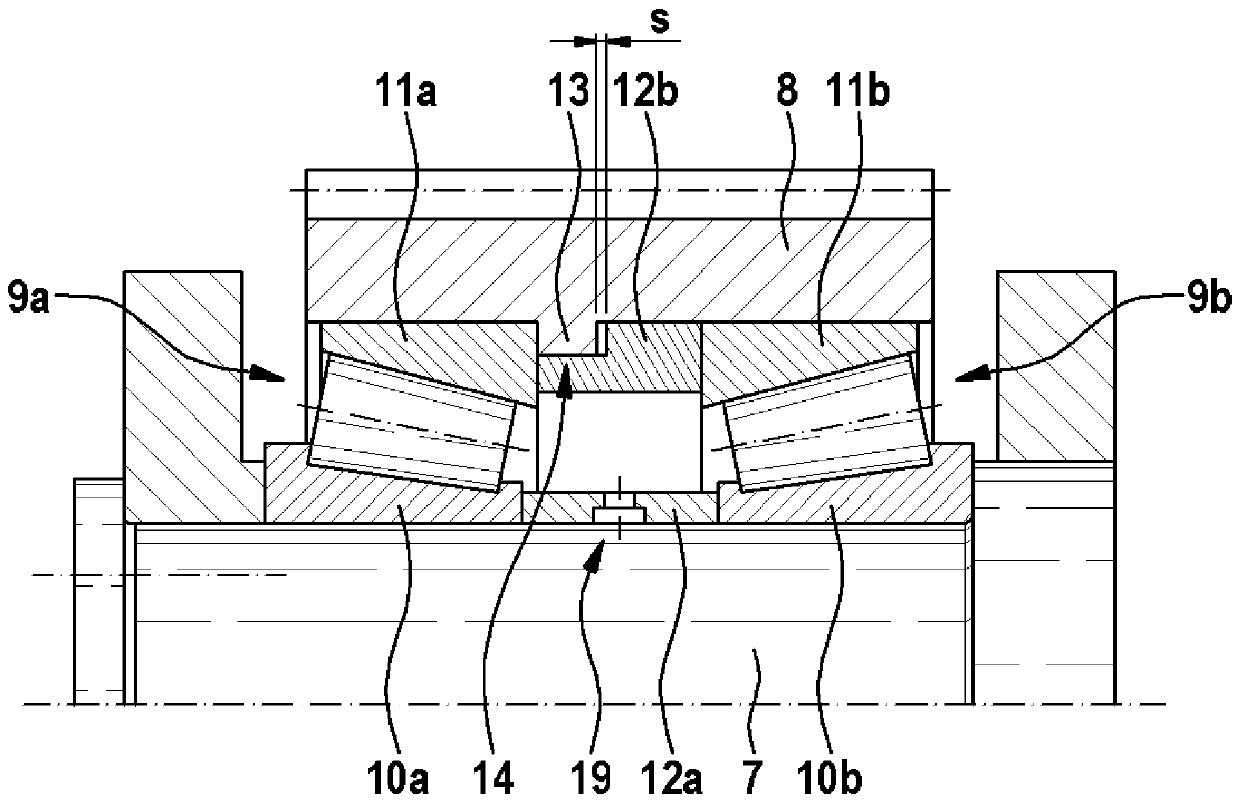

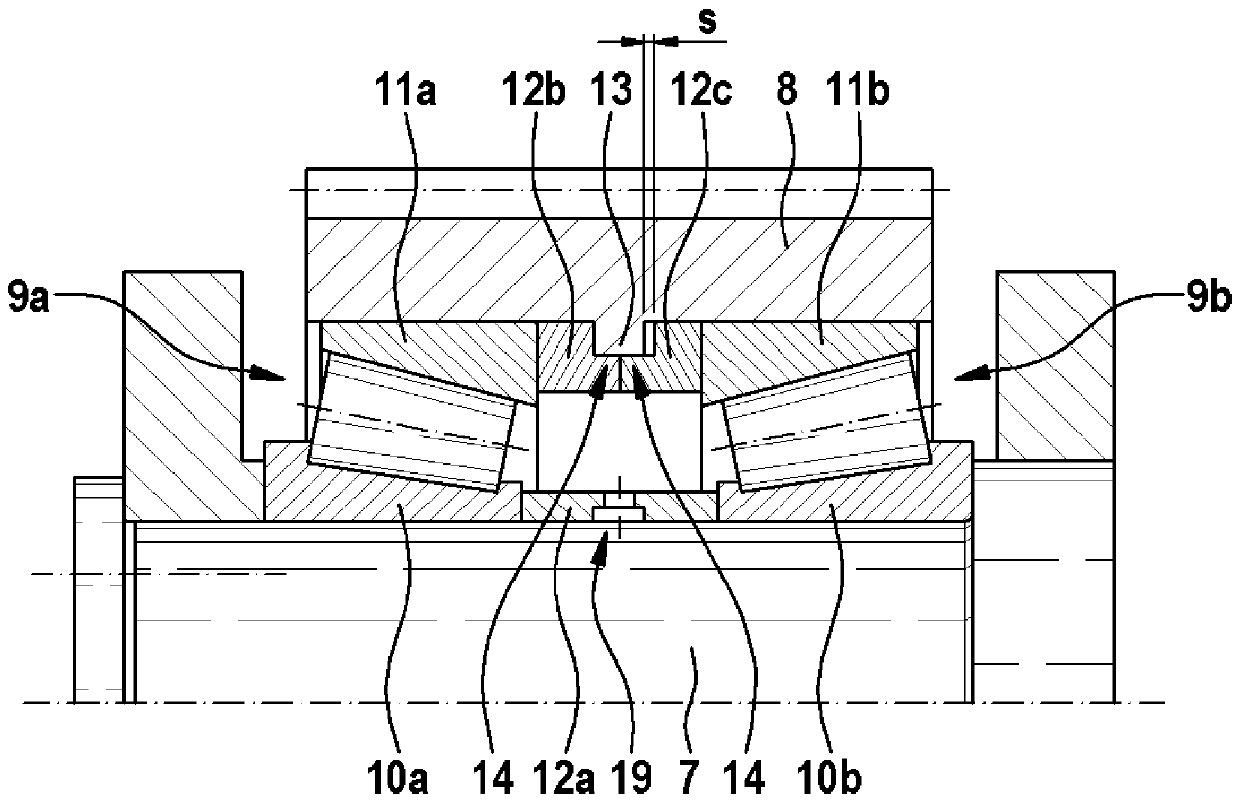

Embodiment Construction

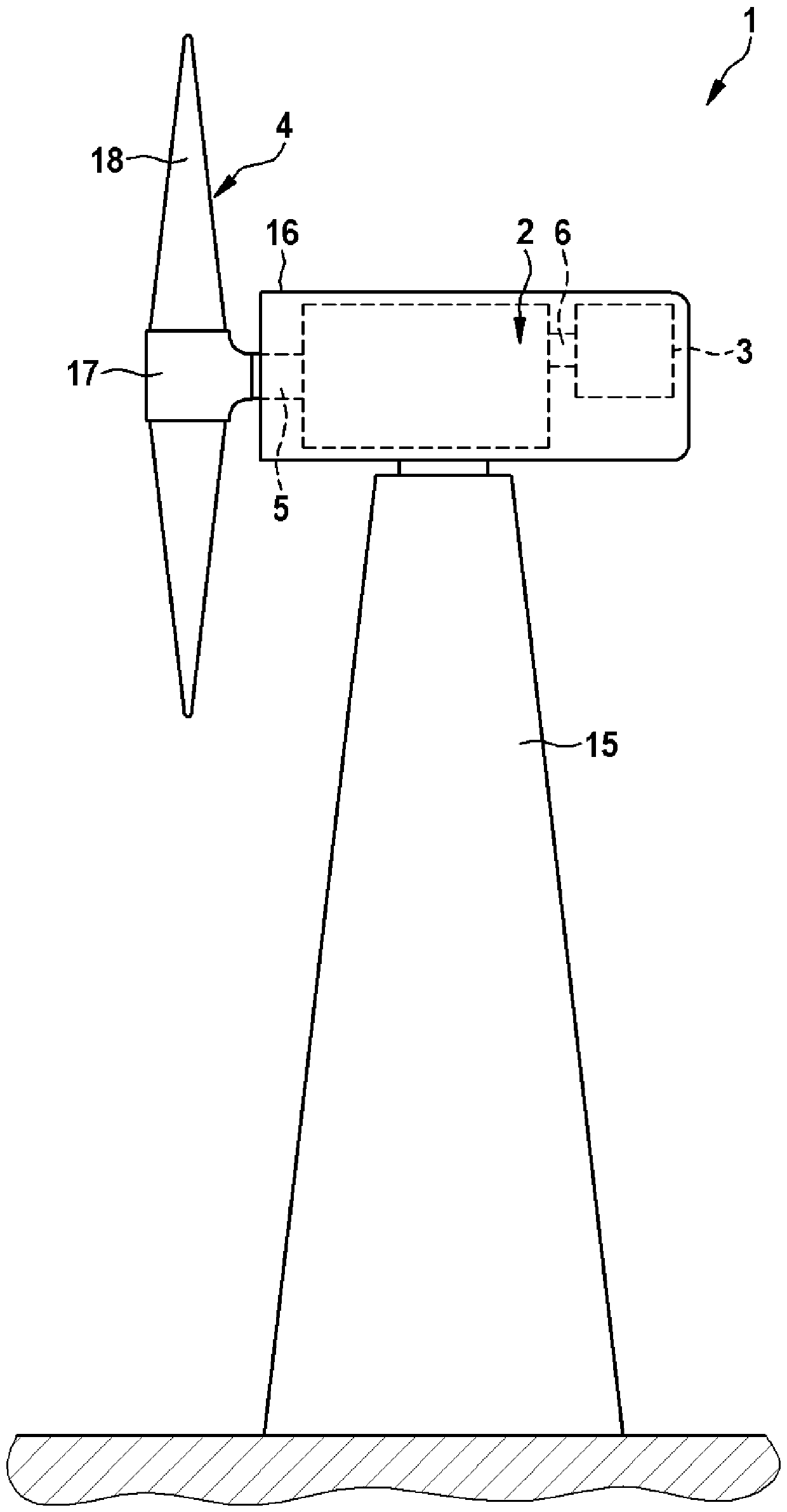

[0021] figure 1 A side view of the wind power plant 1 with its basic components is shown. The wind power plant 1 has a tower 15 on which a nacelle 16 in the form of a machine housing is arranged so as to be rotatable about a vertical axis. A planetary gear 2 is fastened in the gondola 16 in a rotationally fixed manner, wherein the planetary gear 2 has a drive shaft 5 and an output shaft 6 . The drive shaft 5 of the planetary gear 2 is connected to a hub 17 of a rotor 4 with a plurality of rotor blades 18 . The driven shaft 6 is connected in rotation to a drive to be driven in the form of a generator 3 .

[0022] The planetary gear 2 is designed such that it converts a slow rotation of the drive shaft 5 into a fast rotation of the output shaft 6 . To this end, the planetary gear 2 has one or more planetary gear stages, which interact with the output shaft 6 via a closed spur gear. Electric energy is generated by means of a wind power plant 1 by introducing the rotation, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com