Gearbox drive unit

A technology for drive units and transmission components, applied in the direction of transmissions, gear transmissions, components with teeth, etc., can solve problems such as limitations, and achieve the effects of load reduction and load capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

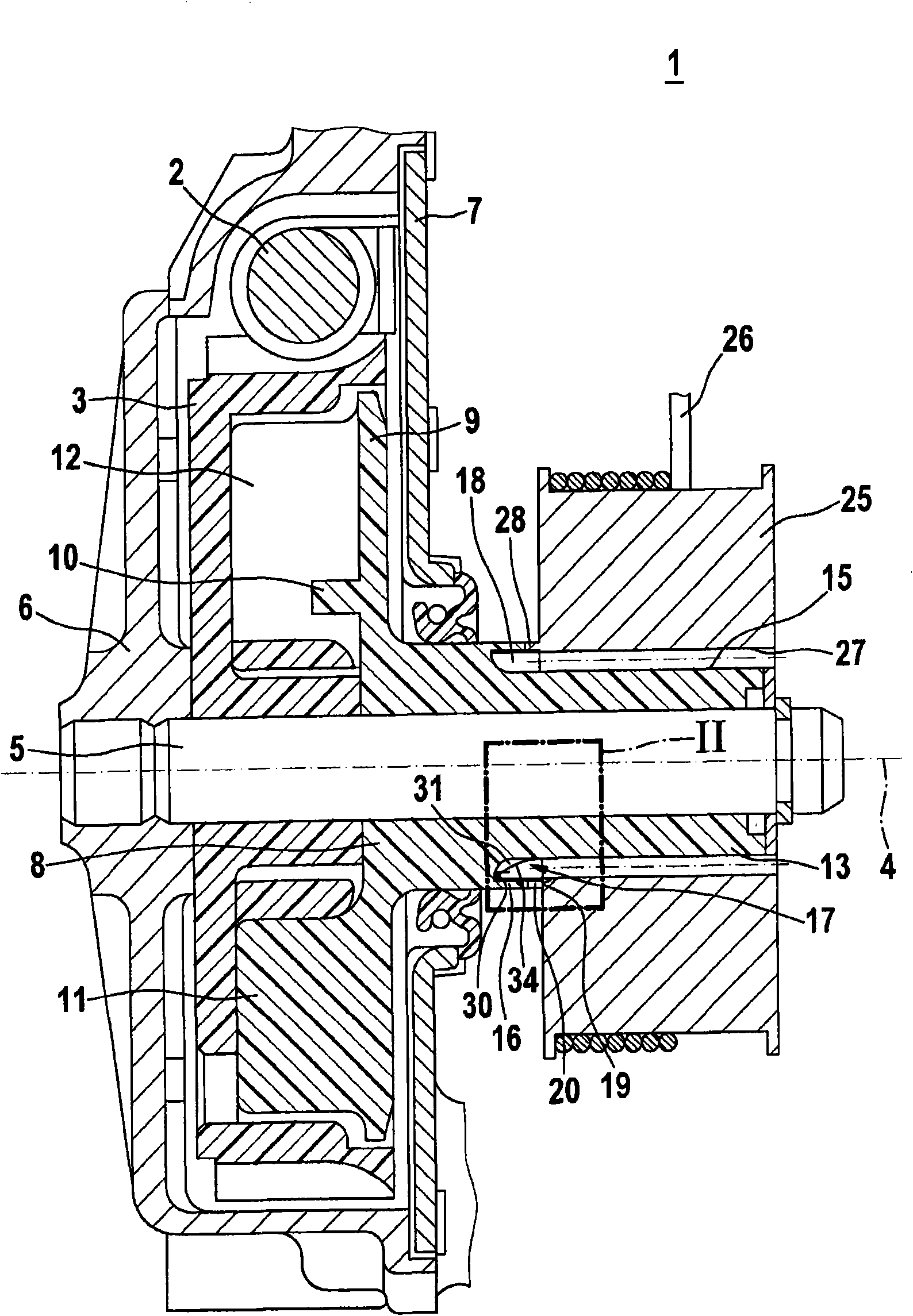

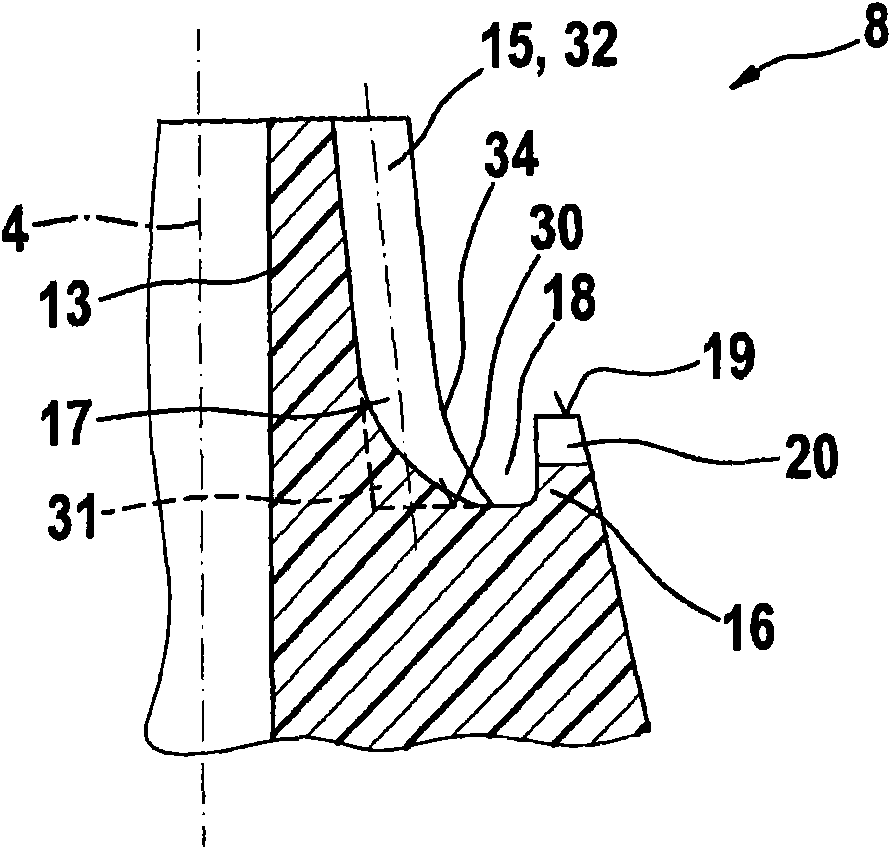

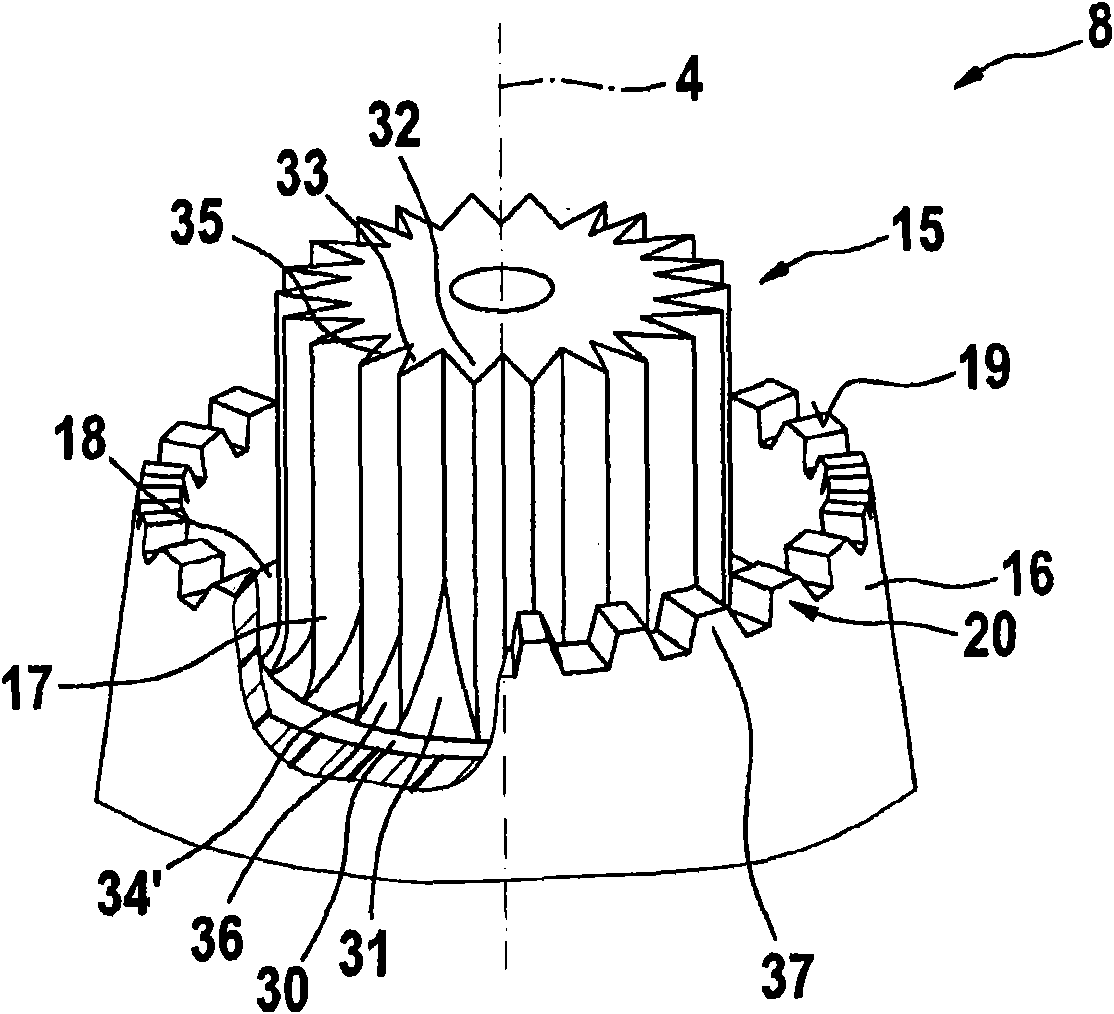

[0018] figure 1 A schematic partial cross-sectional view of the transmission-drive unit 1 of the first embodiment is shown. This transmission-drive unit 1 can be used in particular as an auxiliary drive for assisted operation adjustment or for supporting adjustment of automobile components. For example, the transmission-drive unit 1 can be used to adjust a car window or a car sunroof. However, the transmission-drive unit 1 according to the invention is also suitable for other use cases.

[0019] The transmission-drive unit 1 has a worm shaft 2. This worm shaft is designed, for example, as an extension of the armature shaft of the drive motor. The worm shaft 2 and a worm gear 3 work together. The transmission-drive unit 1 has a rotation axis 4 around which the worm gear 3 driven during operation rotates. In this case, the direction of rotation can be specified by the direction of rotation of the worm shaft 2. In this way, this worm gear 3 can be driven purposefully according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com