A planetary wheel shaft for planetary row load equalization

A planetary axle and planetary row technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problem of planetary row planetary gear transmission life and reliability, friction plates, gears and other parts damage , increased vibration of friction plates, etc., to achieve the effect of improving excessive dynamic load, improving life and reliability, and avoiding excessive meshing dynamic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

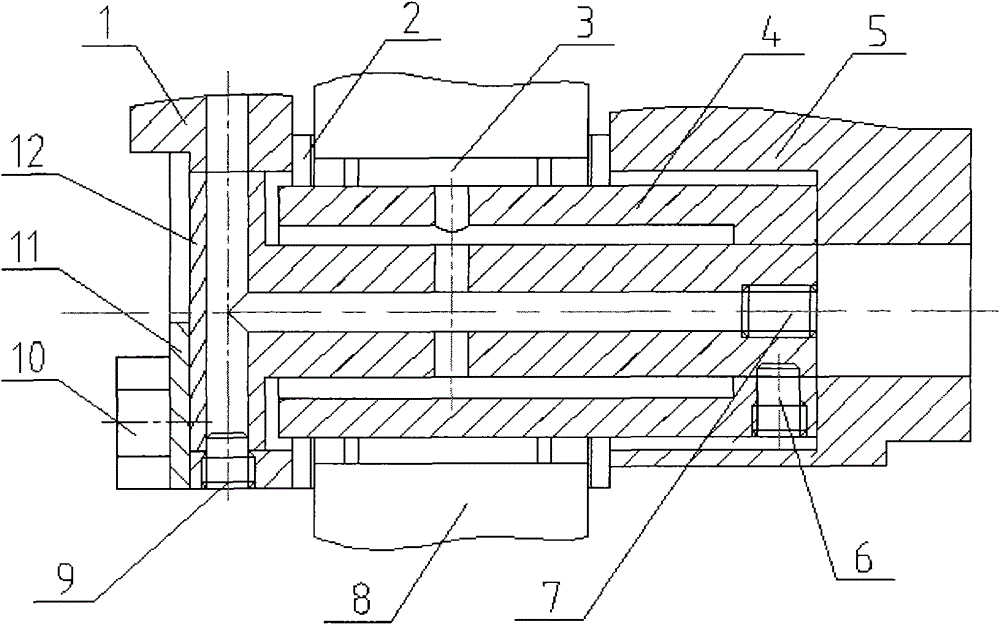

[0015] Such as figure 1 As shown, the planetary gear shaft provided by the present invention for planetary row load equalization is assembled in the transmission, and the planetary gear shaft is composed of a U-shaped shaft 4 and a T-shaped shaft 12, and the U-shaped shaft 4 and the T-shaped shaft 12 are connected by set screws 6 Axially fixed, the oil plug 7 seals the right end of the lubricating oil channel of the T-shaped shaft 12, and the T-shaped shaft 12 is axially fixed on the sub-frame 1 by the set screw 9.

[0016] The U-shaped shaft 4 is designed as a U-shaped structure with a columnar thin-walled interior, and its left end is pushed against the inner hole of the main frame 5, and the inner end of the U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com