Overflowing valve with automatic resetting and zero leakage functions

An automatic reset, zero-leakage technology, applied in functional valve types, lift valves, valve details, etc., can solve problems such as environmental pollution, long valve reset time, waste, etc., and achieve the effect of increasing the adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

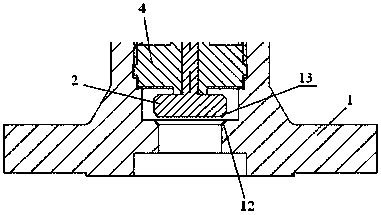

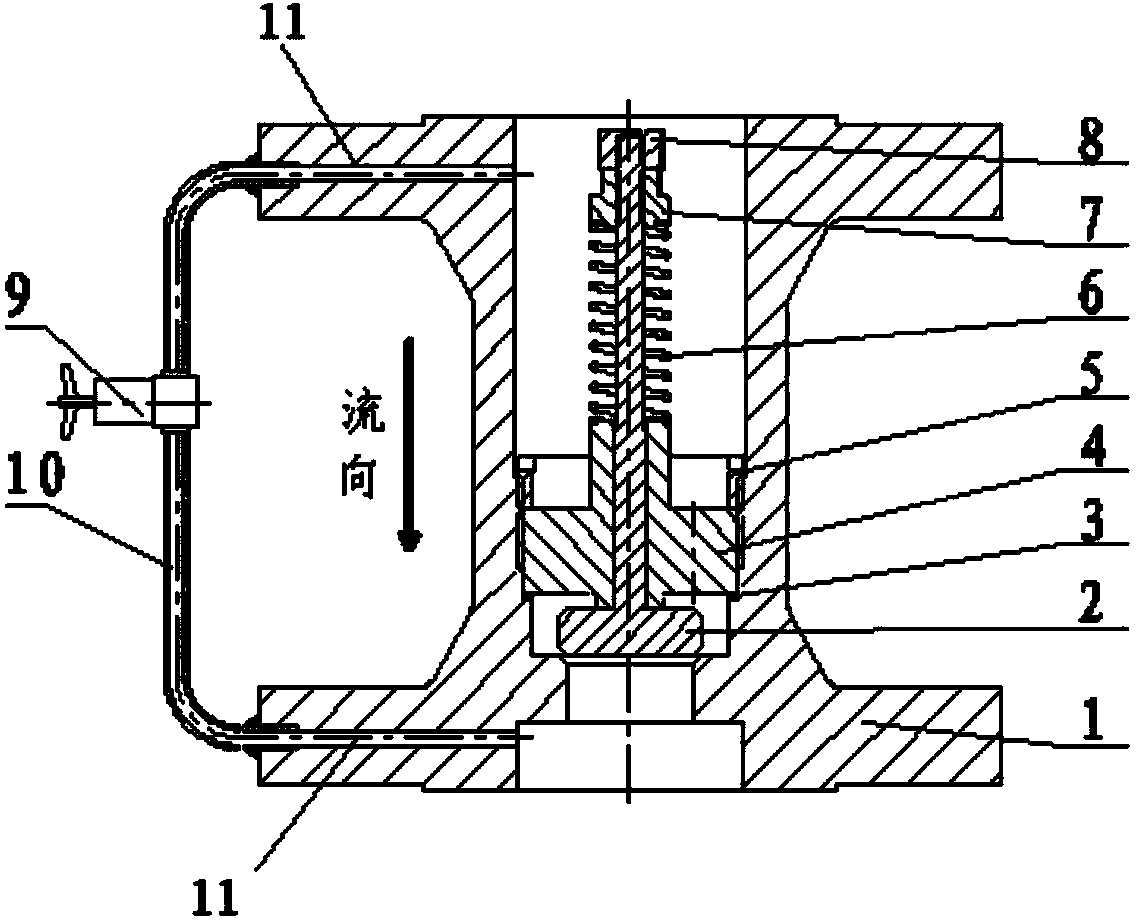

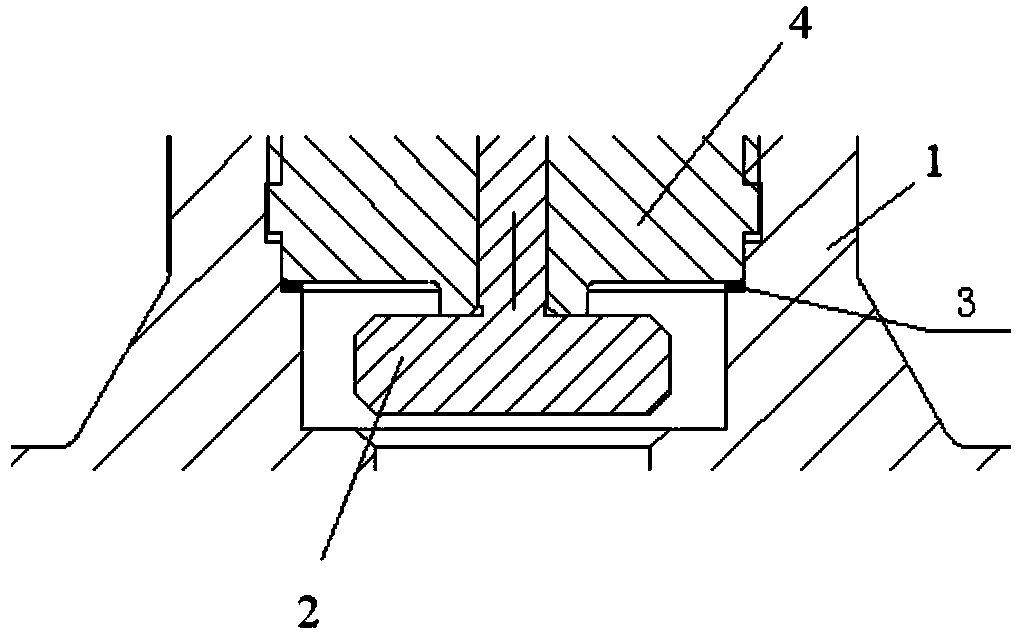

[0023] Such as figure 1 As shown, a through hole is processed in the center of the valve body 1, and the lower end of the through hole is stepped. A valve flap 2 is installed in the through hole, the bottom of the valve flap 2 is a disc, and the top of the disc is rod-shaped. A guide sleeve 4 is sheathed on the rod-shaped outer cover. The center of the guide sleeve 4 is processed with a protruding circular platform structure, and the center is processed with a mounting hole, through which the guide sleeve 4 is set outside the rod-shaped part of the valve disc 2, and a lock is installed on the guide sleeve 4. The tight collar 5 and the locking collar 5 are threadedly connected with the valve body 1, and the guide sleeve 4 is locked by the locking collar 5. The guide sleeve 4 is threadedly connected with the valve body 1 .

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com