Multi-cavity type inner container of small water storage electric water heater

An electric water heater and liner technology, which is applied in the field of multi-chamber liner, can solve the problems such as the temperature of the outlet water falling too fast, and achieve the effect of increasing the rate of hot water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

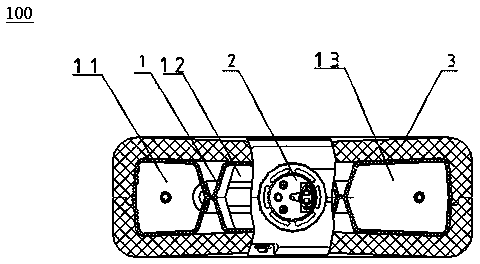

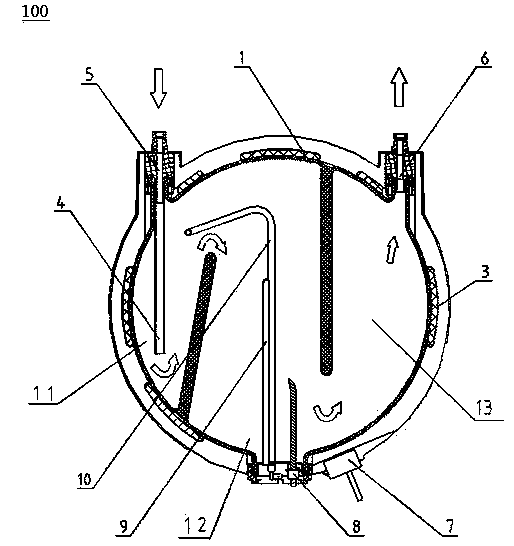

[0017] Such as figure 1 and 2 As shown, a multi-chamber small water storage electric water heater inner tank 100 includes a relatively flat inner tank body 1 with three internal chambers connected in a zigzag shape, including a water inlet chamber 11, a middle chamber 12 and a water outlet chamber 13, The middle cavity 12 is equipped with a heating tube assembly 2, and the heating tube assembly 2 is connected with a heating tube 10, a temperature protector 8 and an adjustable temperature controller 7, and the temperature measuring element of the adjustable temperature controller 7 is inserted into the temperature measuring tube 9 Extend into the water to measure the water temperature. The water inlet chamber 11 on the left side of the three-chamber liner is connected to the water inlet pipe joint 5, and an inner water pipe 4 is connected to the water inlet pipe joint 5. The inner water pipe extends to the bottom of the blind end of the water inlet chamber 11. , the blind end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com