A self-suppression and controlled flow double-nozzle electromagnetic composite casting device

An electromagnetic compounding, double nozzle technology, applied in the field of steel casting, can solve problems such as continuous production, and achieve the effects of suppressing molten steel mixing, reducing temperature difference and density difference, and suppressing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific embodiments.

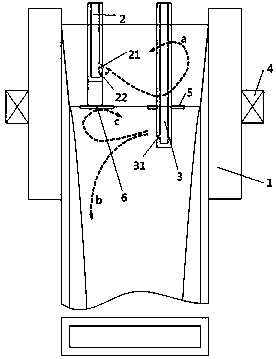

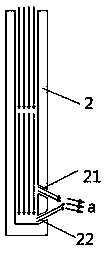

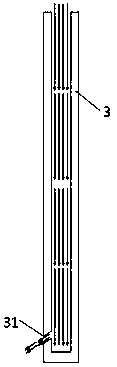

[0024] A self-inhibiting and flow-controlled double nozzle electromagnetic composite casting device, such as Figure 1-3 As shown, it includes a crystallizer 1, a self-suppressing submerged double nozzle device and an electromagnetic field generating device; the self-suppressing submerged double nozzle device includes a vertically arranged short submerged nozzle 2 and a long submerged nozzle 3, two Both are in the shape of a tube with an upper end opening; the insertion depth of the short submerged nozzle 2 in the crystallizer 1 is less than the insertion depth of the long submerged nozzle 3; the short submerged nozzle 2 and the long submerged nozzle The lower end of the nozzle 3 is respectively provided with a short submerged tapping side hole 21 and a long submerged tapping side hole 31 inclined downward, which are respectively used to lead out the upper layer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com