Display module, its front panel assembly, and method for assembling the display module

A display panel and display module technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem of not being able to achieve the effect of ultra-narrow borders and narrow edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

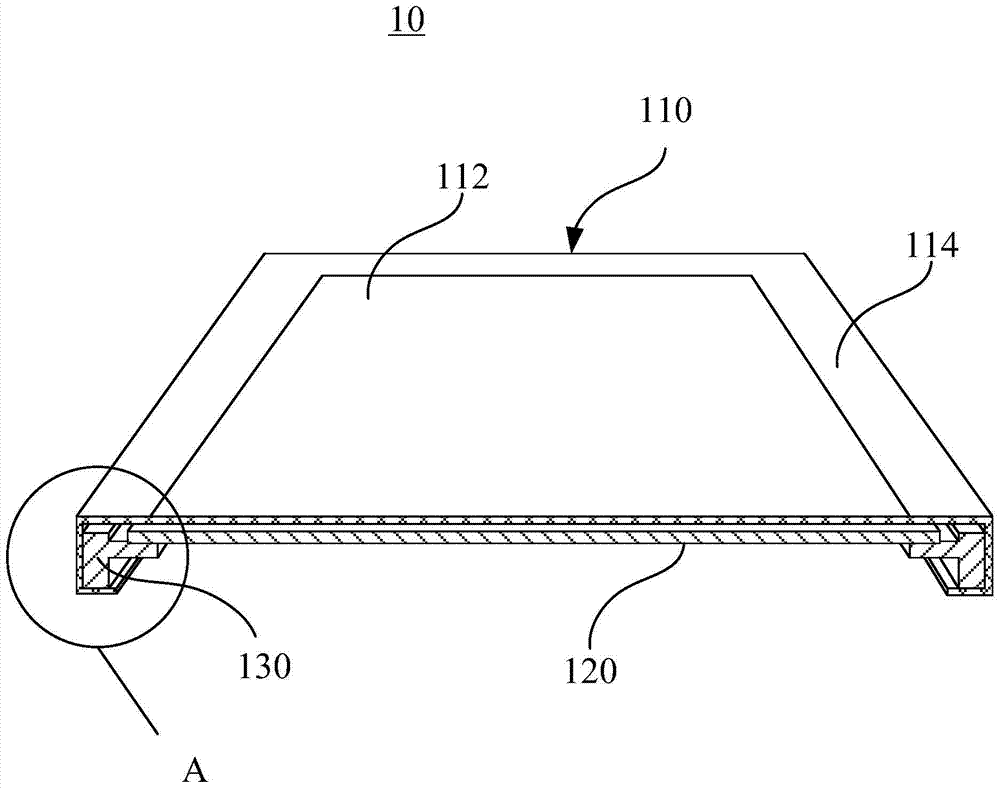

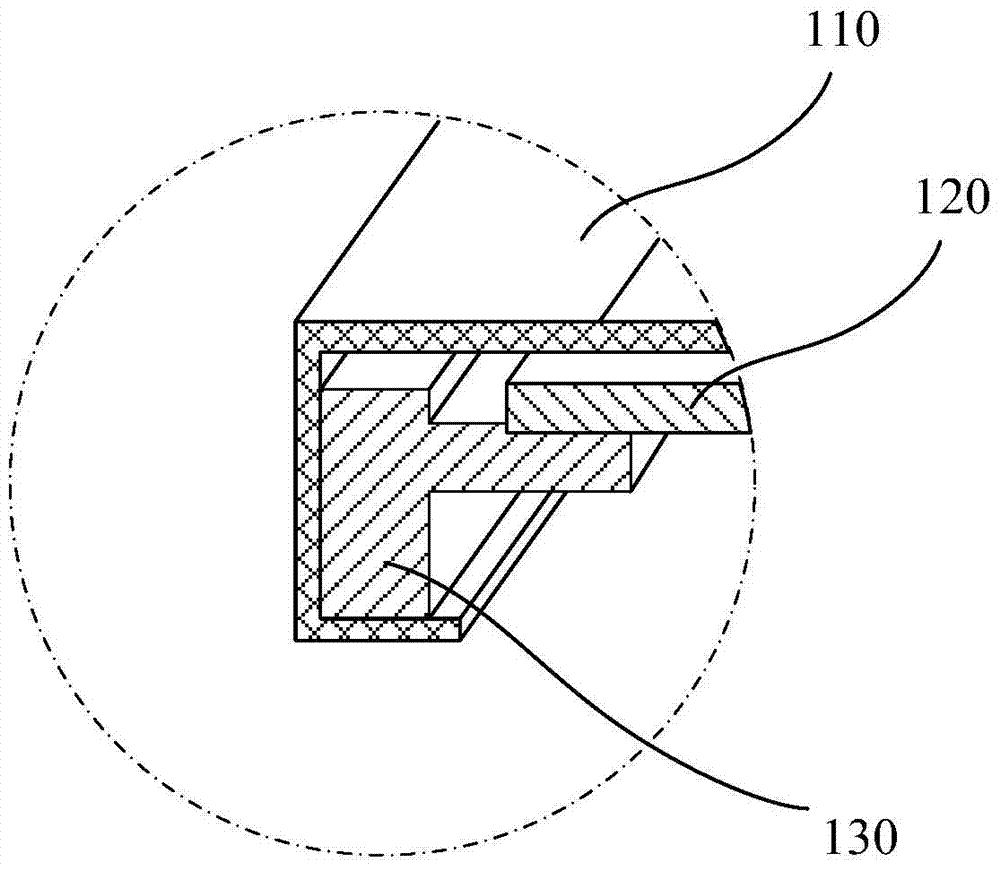

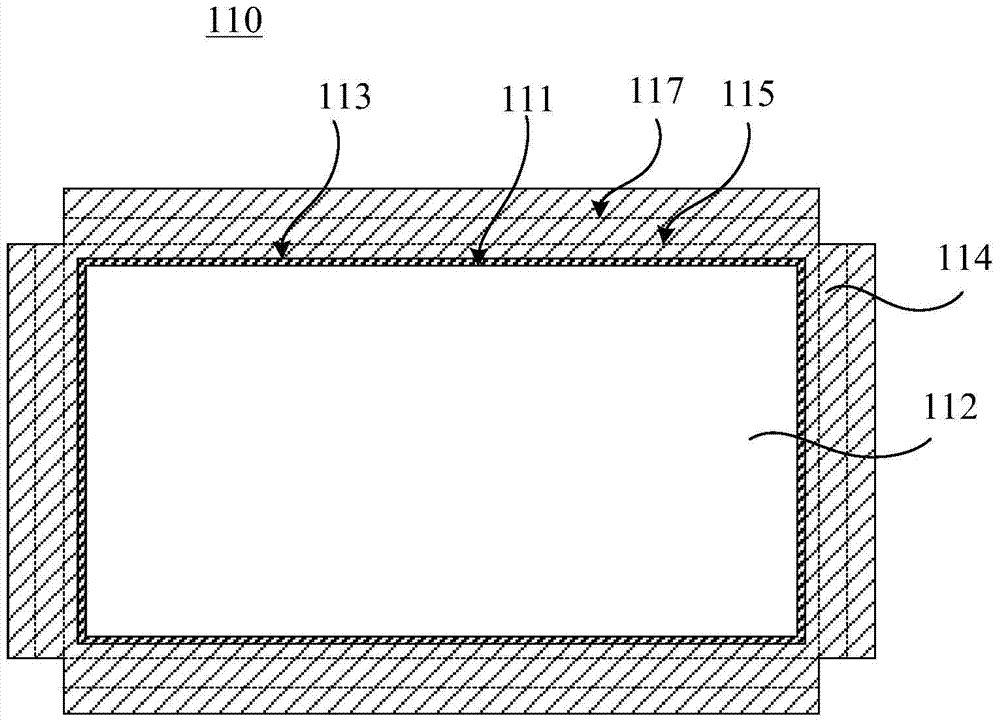

[0027] figure 1 is a cross-sectional structure diagram of a front panel assembly of a display module in an embodiment, figure 2 for figure 1 Enlarged view of part A in the middle. Such as figure 1 and figure 2 As shown, the front panel assembly 10 includes a diaphragm 110 , a display panel 120 and a plastic frame 130 . The film 110 covers the display surface of the display panel 120 , and bends and extends toward the side and the back side of the display panel 120 at the edge of the display panel 120 . The size of the plastic frame 130 matches the size of the display panel 120. The plastic frame 130 is arranged on the back side of the display panel 120 to abut against the display panel 120, and the four sides of the plastic frame 130 extend to the sides of the display panel 120 along with the diaphragm 120. The side part is fixedly connected.

[0028] The diaphragm 110 is made of polyethylene terephthalate (PET), which has a certain tensile strength. The diaphragm 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com