Dispersion device for triaxial viscous slurry

A slurry and viscosity technology, applied in the field of material stirring and dispersing equipment, can solve the problems of difficult separation of useful minerals, flocculation of fine particles, and inability to disperse slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

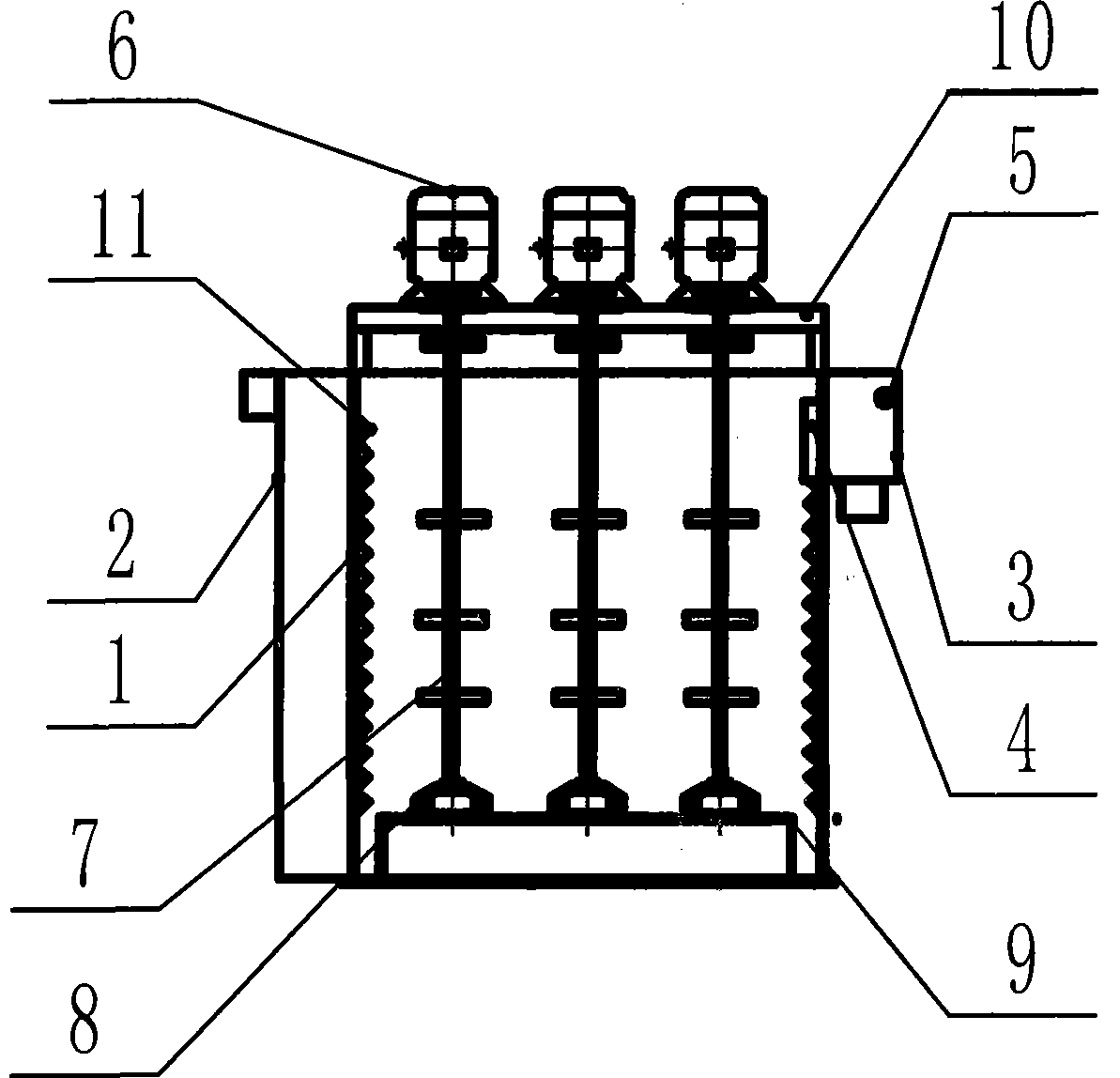

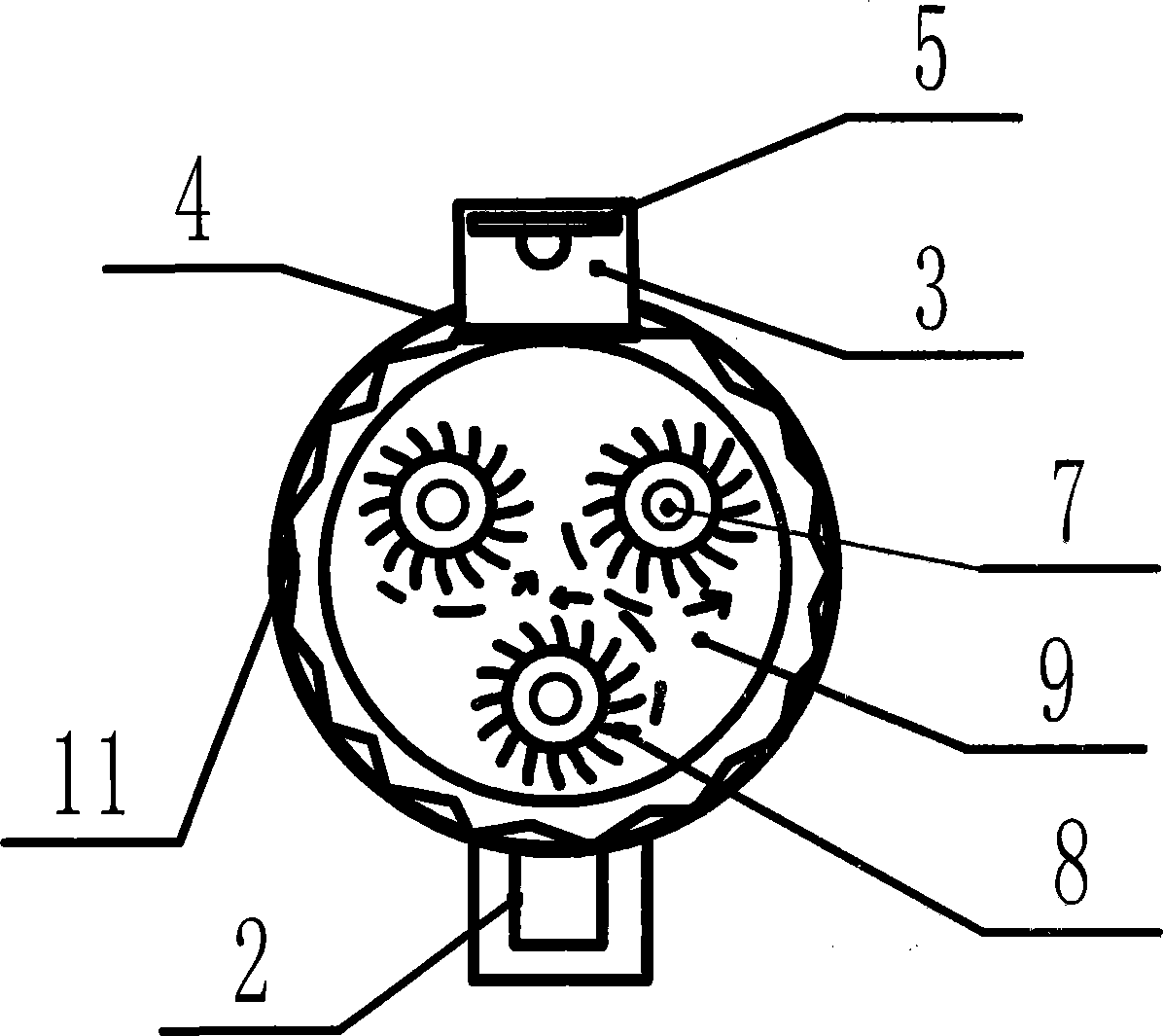

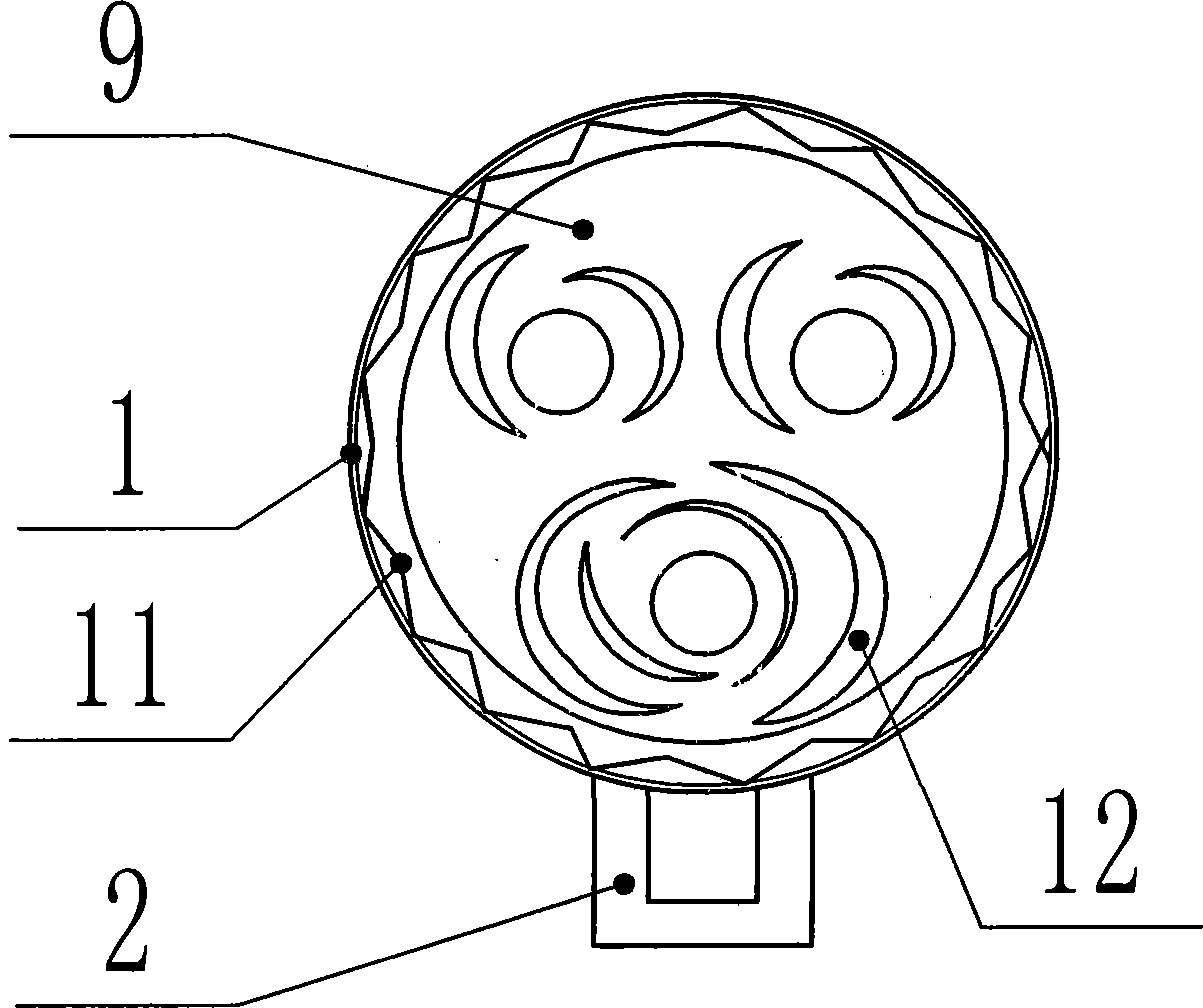

[0013] Attached below figure 1 , figure 2 and image 3 And the embodiment describes the present invention in detail:

[0014] The diameter of the circular cylinder (1) is 1.9 times the side length of the equilateral triangle formed by the centerlines of the three stirring bearings, and a wave shear plate (11) is arranged on the inner wall of the circular cylinder (1). The bottom of the cylinder (1) is provided with a stabilizing plate (9), and the stabilizing plate (9) is provided with a guide plate (12) and three pressure transmission holes, the size of the pressure transmission holes is the same as that of the stirring impeller (8 ) are equal in size, the slurry is automatically sucked into the circular cylinder from the feed inlet (2) by the pressure difference, and thrown out from the gap between the pressure stabilizing plate (9) and the inner wall of the circular cylinder (1). The slurry collides with each other between the master stirring device and the slave stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com