A sprue optimization structure and method for accelerating the flow rate of molten iron

A technology to optimize the structure and flow rate, which is applied in the direction of metal processing equipment, casting molding equipment, casting mold composition, etc., can solve the problems of liquid metal temperature drop, long pouring time, slow flow rate, etc., to avoid excessive speed and increase the surface quality, the effect of avoiding shock effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

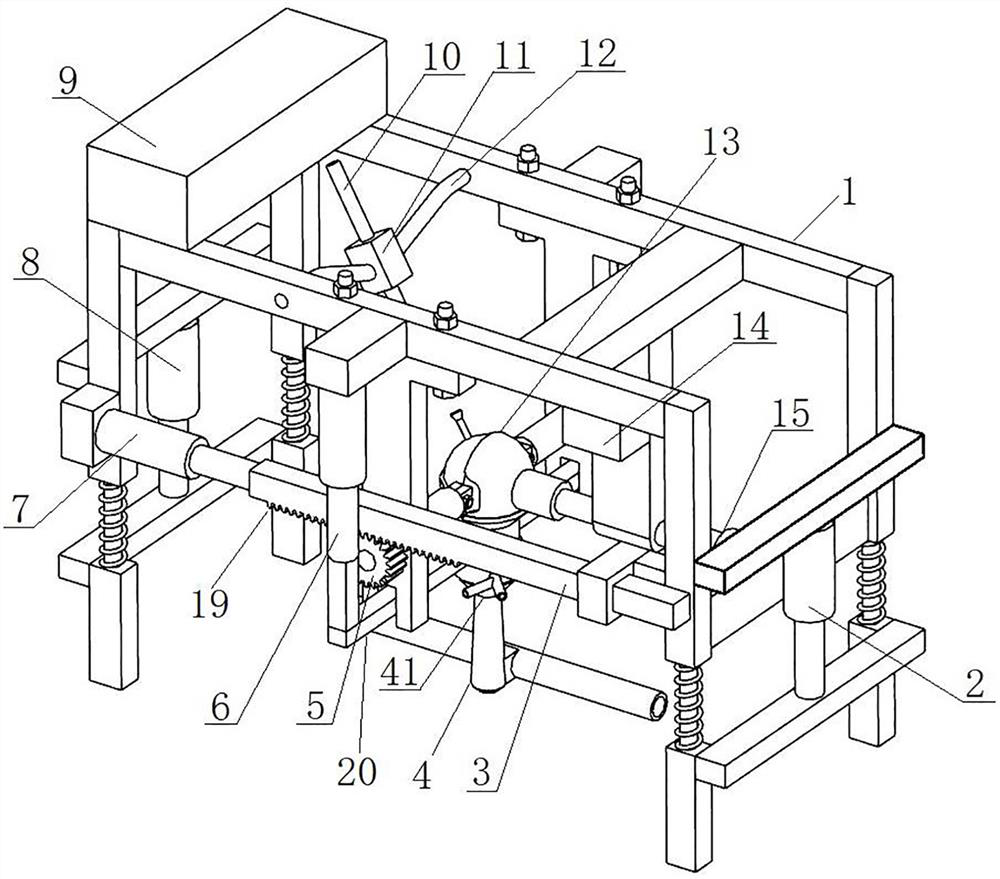

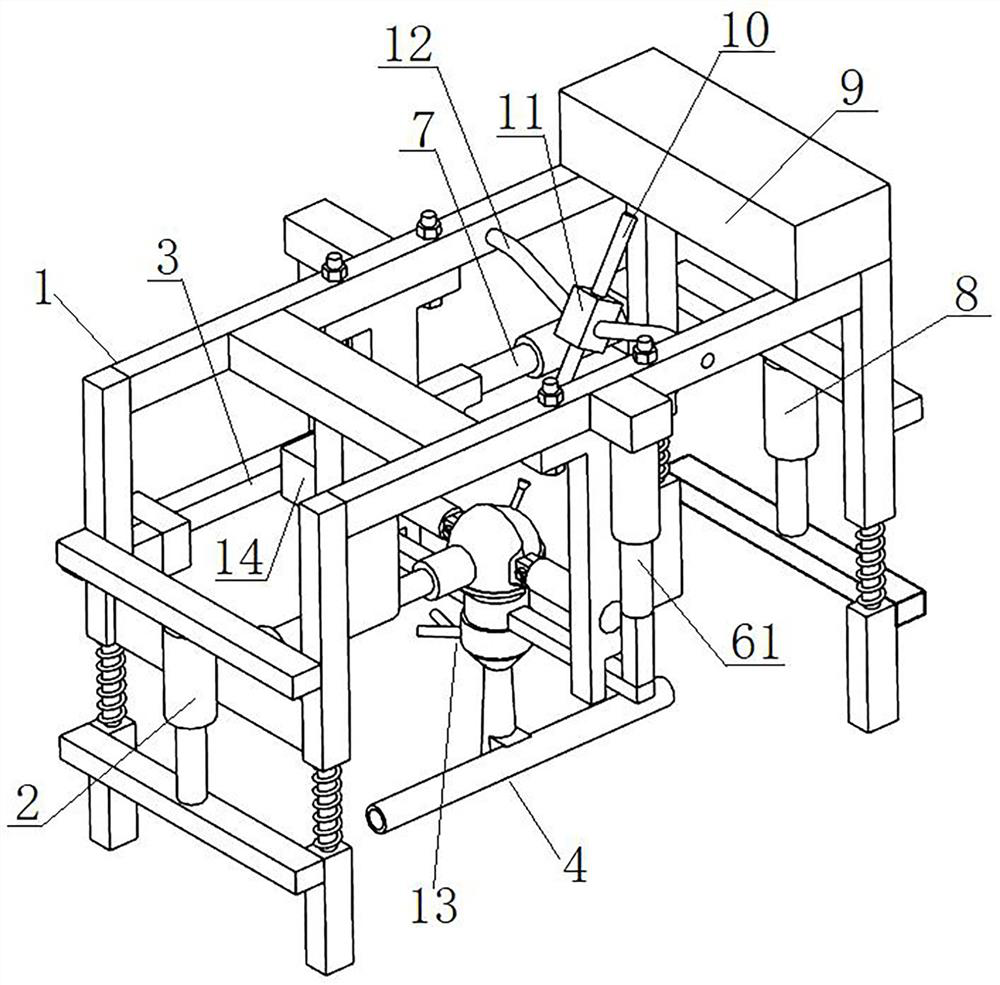

[0045] see figure 1 and figure 2 , a sprue optimization structure for accelerating the flow rate of molten iron, including a gating system 4, the gating system 4 includes an inrunner, a runner, a sprue, and a sprue cup 41 arranged at the top of the sprue, and the sprue cup 41 and the sprue The tundish system 13 is docked, and the tundish system 13 is arranged on the support 1;

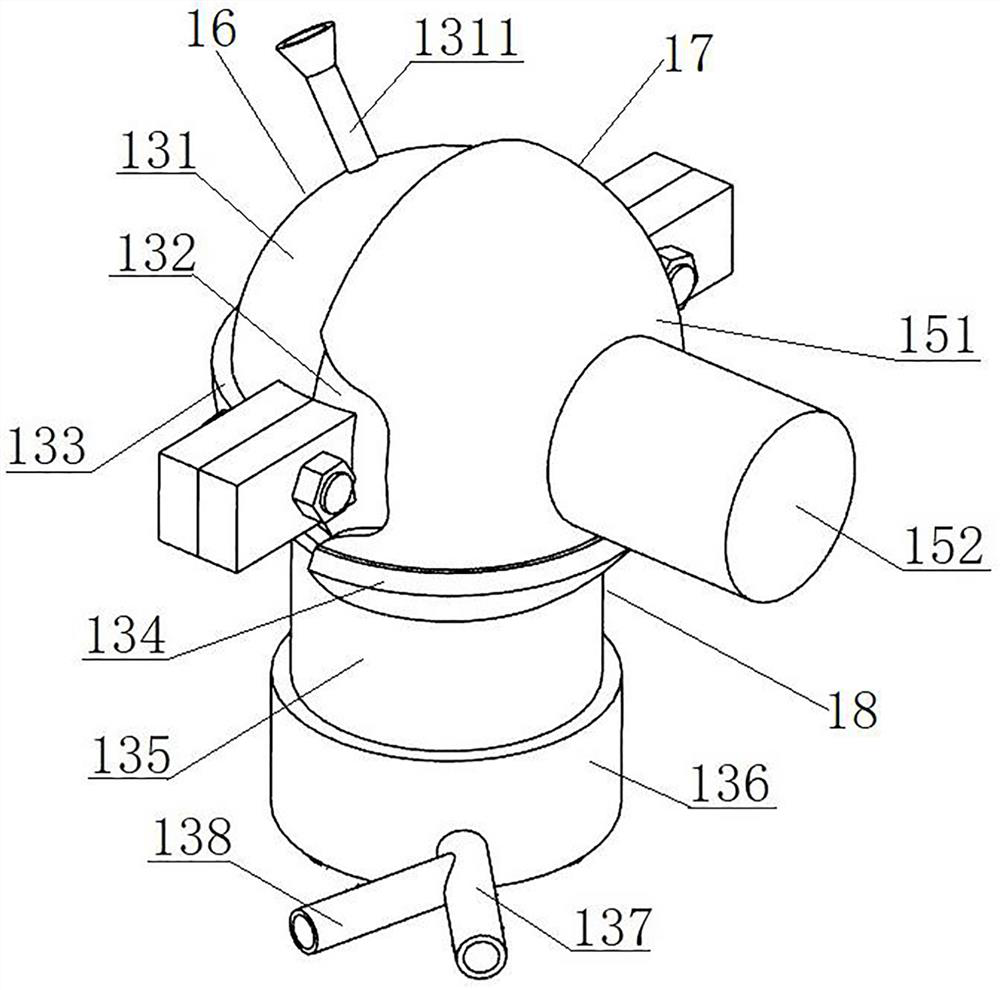

[0046] see image 3 and Figure 5 The tundish system 13 includes a tundish 16, an upper closed structure 17 connected to the side of the tundish 16, a lower closed structure 18 connected to the bottom of the tundish 16, and the tundish 16 is also connected to the shielding gas device 9 and the rotary drive mechanism 19 ;

[0047] The bottom of the lower closed structure 18 is docked with the sprue cup 41, the side of the lower closed stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com