Air supplement device capable of maintaining negative pressure stability of flat-bag dust collector and operating method

A technology of supplementary air device and dust remover, which is applied in chemical instruments and methods, separation methods, program control in sequence/logic controllers, etc., and can solve the problems of affecting the sensory quality of cigarettes, cigarette shorts and end falling, and reducing Cigarette weight stability, cigarette suction resistance stability and other issues, to achieve the effect of simple structure, reducing the influence of negative pressure of the main pipe, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

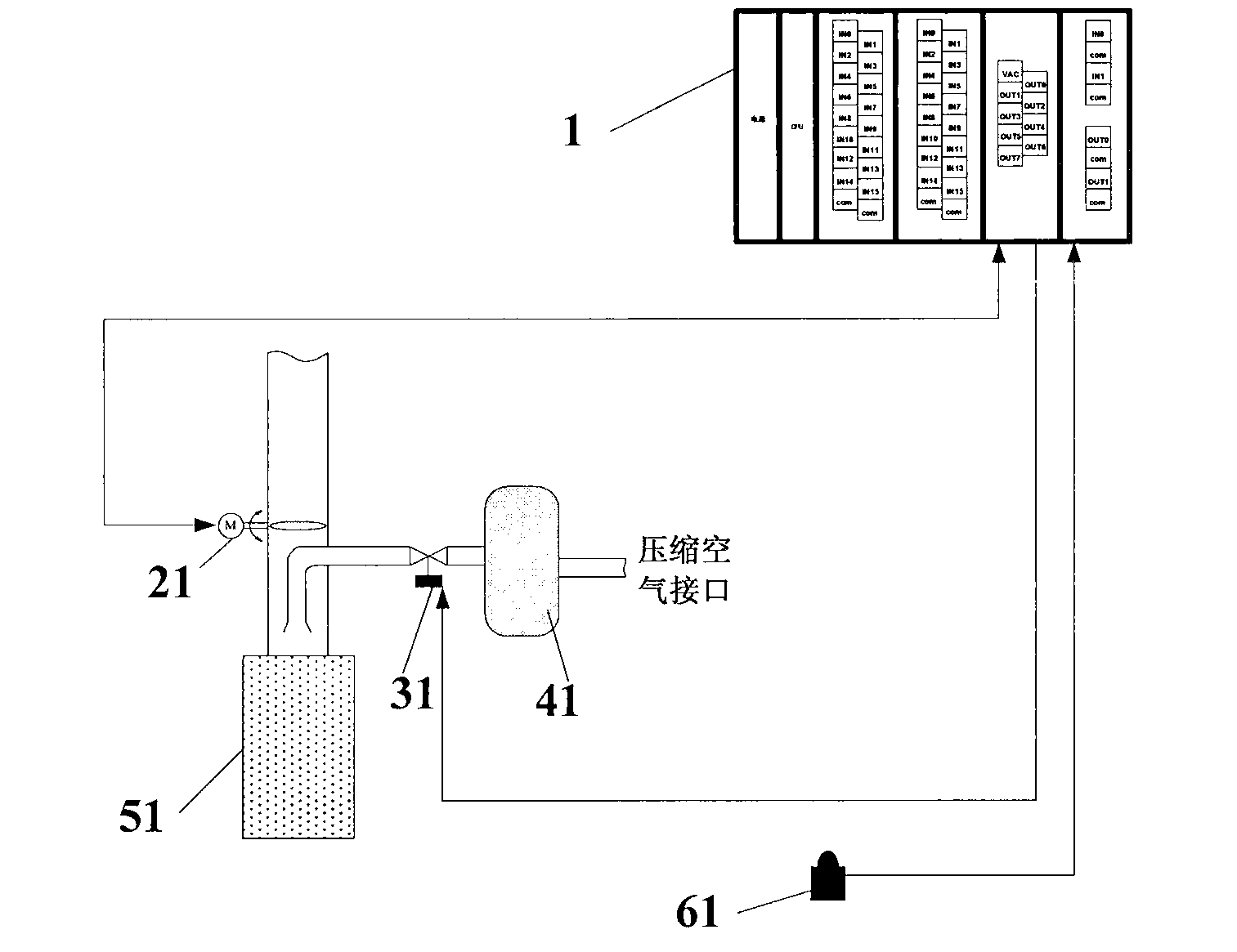

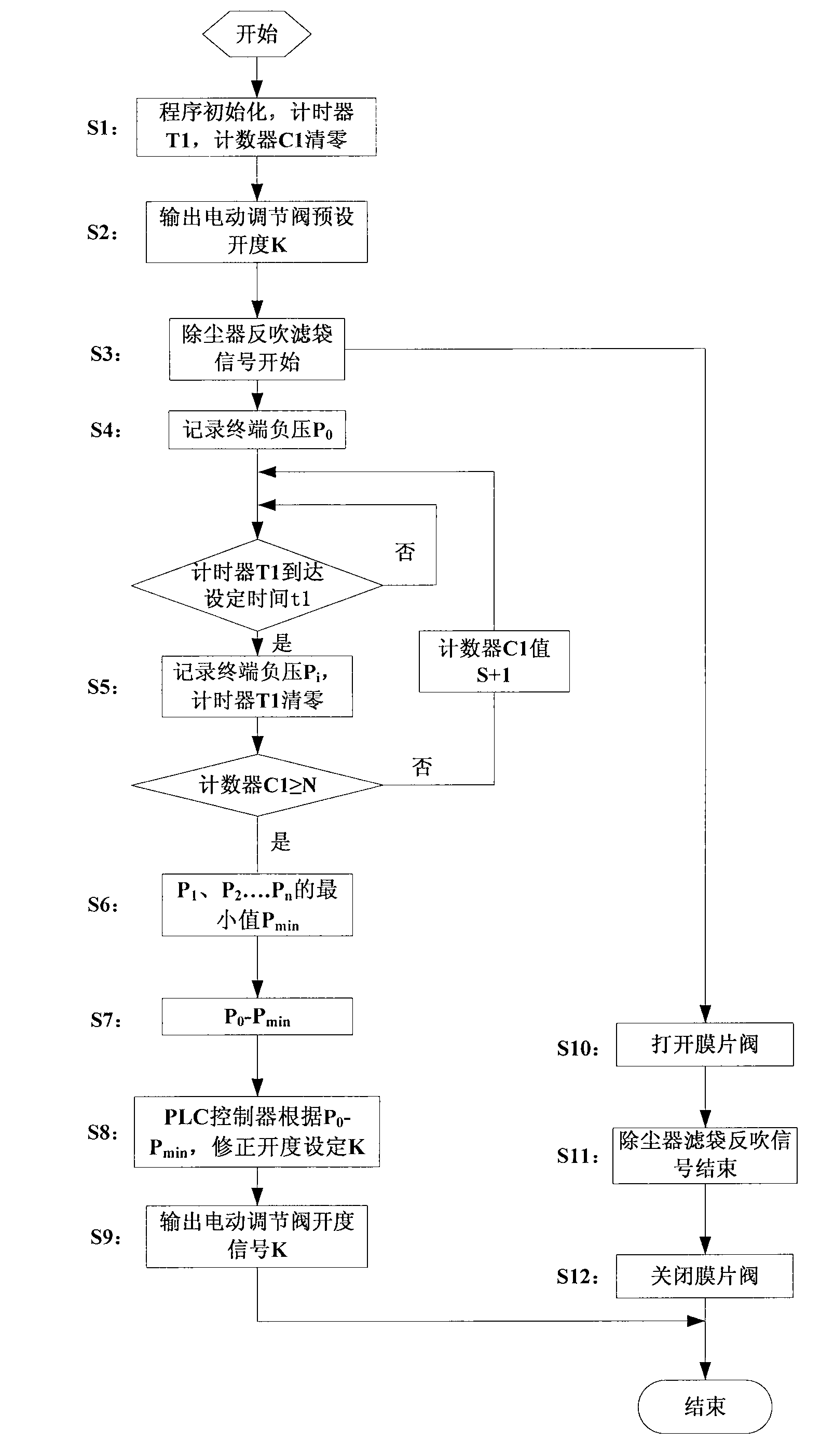

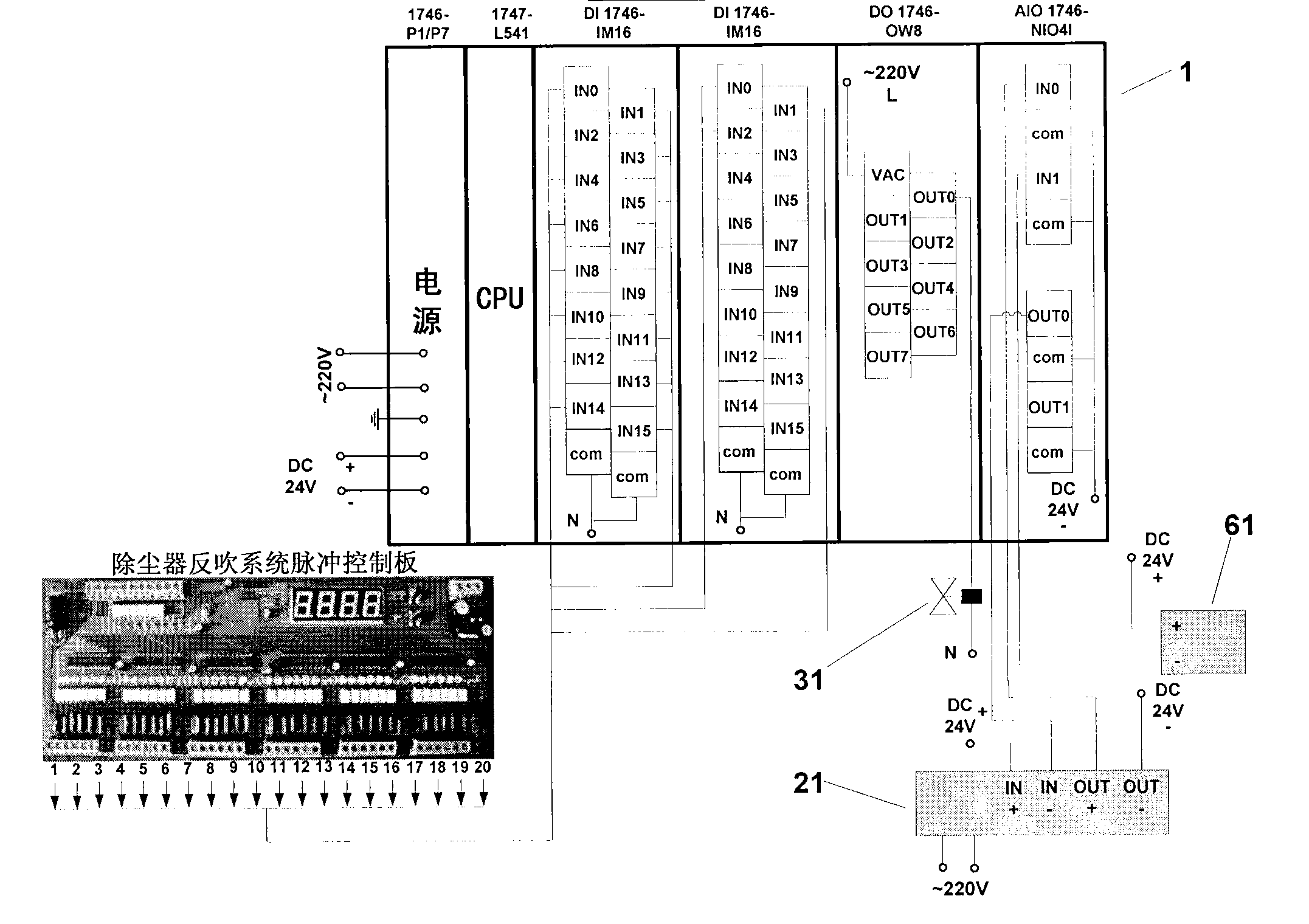

[0030] In conjunction with the accompanying drawings, the description includes a programmable logic controller PLC (1), an electric regulating valve (21), a diaphragm valve (31); a cylinder (41), a muffler (51), a negative pressure sensor (61); The blowback signal of the bag filter to the filter bag, the feedback signal of the negative pressure sensor (61) and the opening of the electric control valve (21) are connected to the input port of the programmable logic controller PLC (1), and the programmable logic controller PLC The output port of (1) is connected with the opening setting signal of the electric regulating valve (21) and the diaphragm valve (31). The operation steps of the device are:

[0031] S1, program initialization, timer T1 and counter C1 are cleared;

[0032] S2. The programmable logic controller PLC (1) outputs an instruction to open the electric regulating valve (21) to a preset opening degree K;

[0033] S3. If the filter bag backflush signal is detected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com