Composite type mycotoxin adsorbent and preparation method thereof

A mycotoxin adsorption, compound mold technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of weak adsorption capacity, low adsorption rate, low DON adsorption rate, etc., and achieve the effect of good adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Evaluation method of mycotoxin adsorption capacity: Prepare a buffer solution of dipotassium hydrogen phosphate, adjust the pH of the solution to 3.0 with phosphoric acid (simulating the pH environment of the animal stomach), add the toxin standard to the buffer solution, and prepare a toxin content of 3MG / KG buffer solution. Add the adsorbent to the toxin buffer solution, shake at a constant temperature of 37°C for 3 hours, centrifuge, test the toxin content in the supernatant with a liquid chromatograph, and set up a control group (buffer solution with toxin added, no adsorbent). Toxin amount in the supernatant (adsorption stage) / toxin content in the control group 100%=% toxin amount adsorbed.

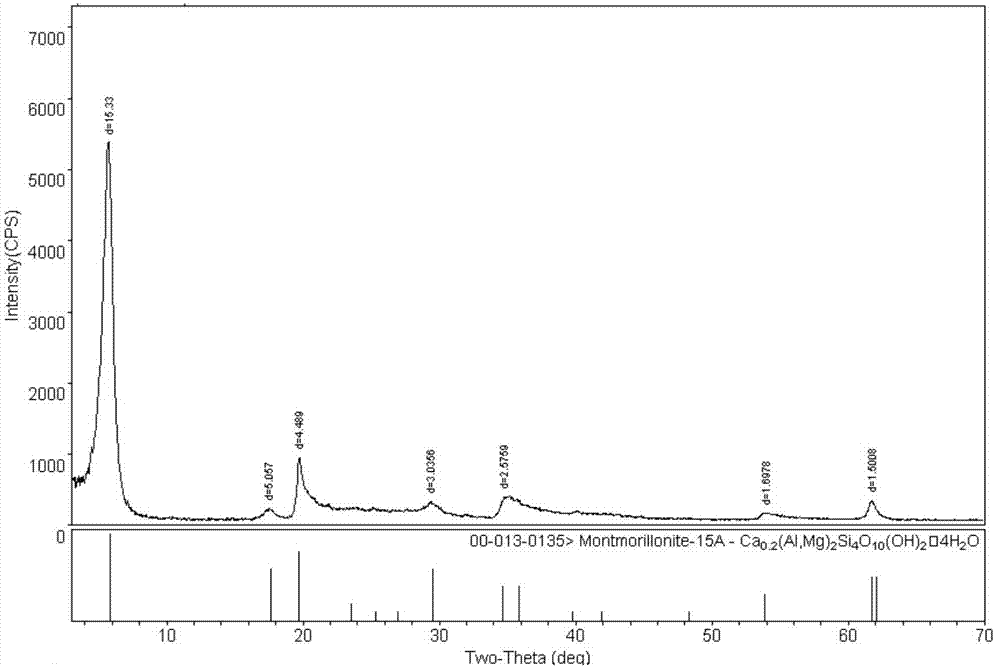

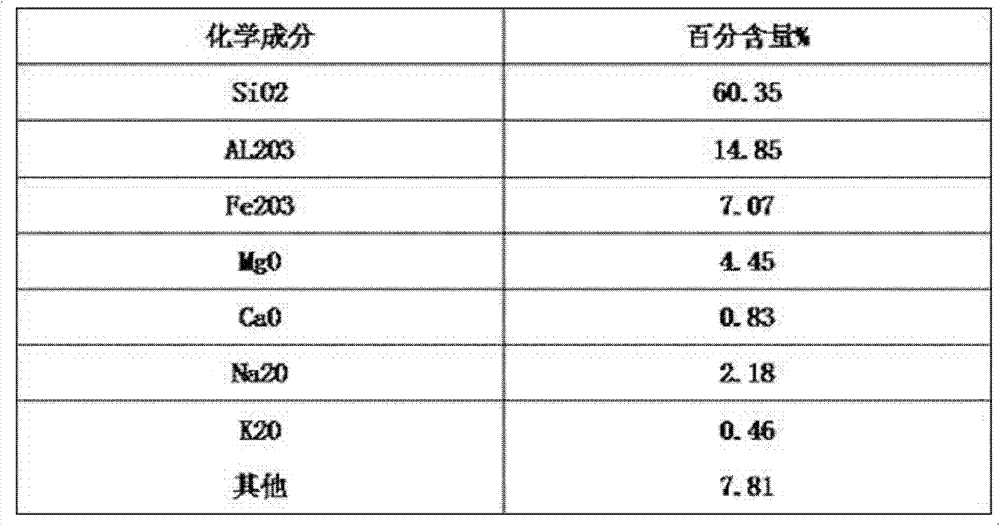

[0028] The adsorption test of high-purity montmorillonite to aflatoxin, zearalenone and ochratoxin, the test method is as above. The basic properties of high-purity montmorillonite: the chemical composition of high-purity montmorillonite is shown in Table 1-1, and the phase c...

Embodiment 2

[0035] Preparation of surface-modified montmorillonite and its ability to absorb toxins.

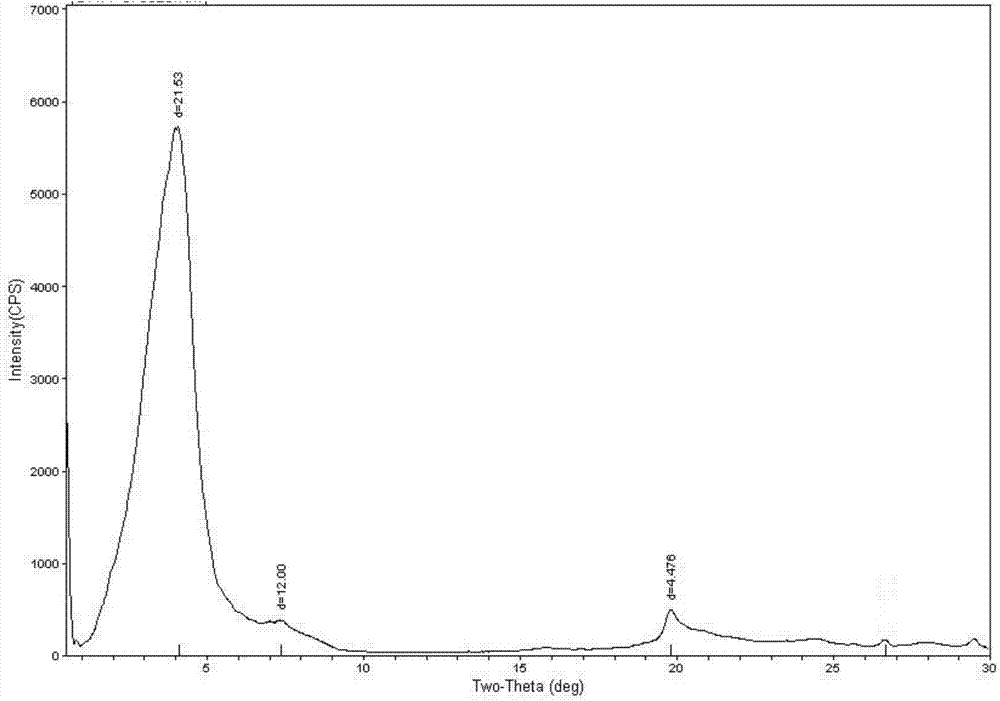

[0036] Weigh a certain amount of bentonite raw material (same as the raw material described in Example 1), beat, and wet-purify to obtain a purified montmorillonite slurry with a solid content of 3-5%, raise the temperature to 70 ° C, stir at a constant temperature and add surface modification Additive agent (cetyl quaternary ammonium salt: amino acid = 8:2), the amount of surface modifier is 1.0 times of the cation exchange capacity of montmorillonite, constant temperature stirring for 2h, press filter dehydration, washing, drying and milling , to obtain surface-modified montmorillonite. Phase analysis of surface modified montmorillonite such as figure 2 shown.

[0037] Surface modified montmorillonite is the same as Example 1 for the test method of mycotoxin adsorption capacity.

[0038] Table 2-1. Data on the adsorption capacity of surface-modified montmorillonite to mycotoxins

...

Embodiment 3

[0042] Preparation of carbon-coated montmorillonite and its ability to adsorb mycotoxins.

[0043] A certain amount of high-purity montmorillonite was weighed, dispersed in 15% hydrochloric acid solution, stirred and soaked for 1 day, washed and dehydrated to obtain a thick slurry of acidified montmorillonite.

[0044] After cleaning the coconut shell, dry and grind it to obtain clean coconut shell powder, stir and soak the coconut shell powder with 40% hydrochloric acid solution for 2 days, and dehydrate to obtain a thick slurry of acidified coconut shell powder.

[0045] In the state of stirring, the thick slurry of acidified coconut shell powder and the thick slurry of acidified montmorillonite were uniformly mixed according to the mass ratio of 8:2, carbonized at 700°C, and pulverized to obtain carbon-coated montmorillonite. The method for testing the adsorption capacity of carbon-coated montmorillonite to mycotoxins is the same as in Example 1.

[0046] Table 3-1. Mycotoxi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap