Element disassembling mechanism of acupuncture needle automatic handle winding machine

An acupuncture needle and handle winding machine technology, which is applied to needles, other household appliances, household appliances, etc., can solve the problem that the unloading mechanism is not described in detail, and achieve the effects of ingenious structure, ingenious mechanism and flexible action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

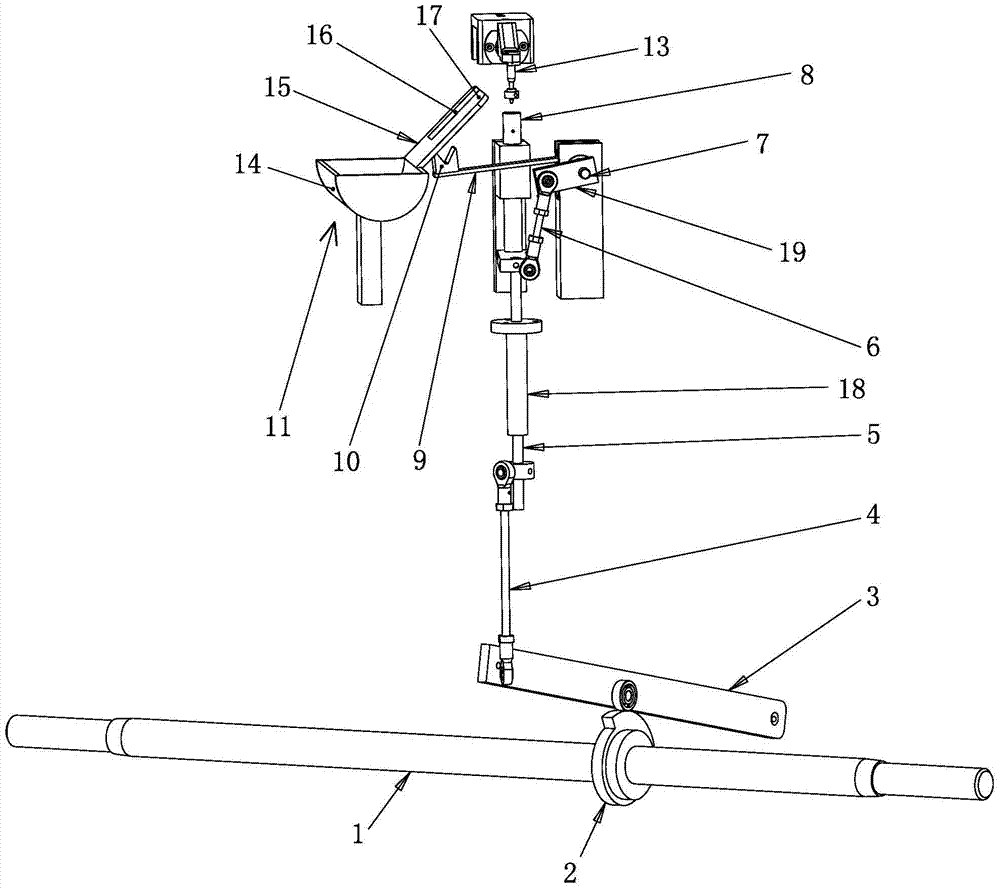

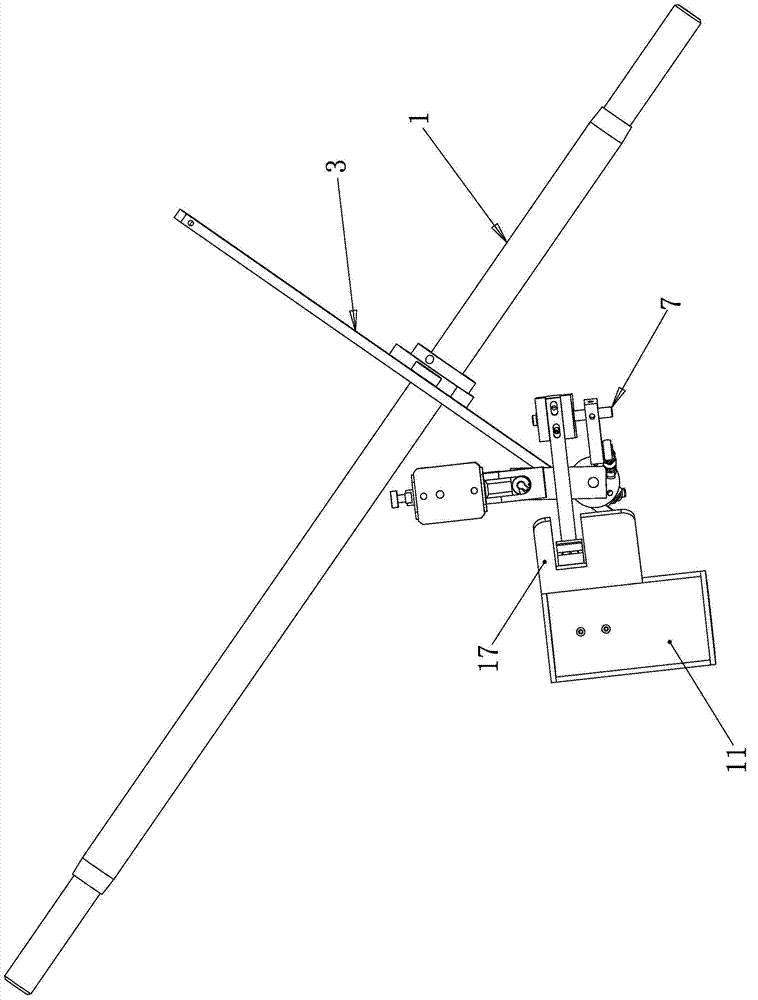

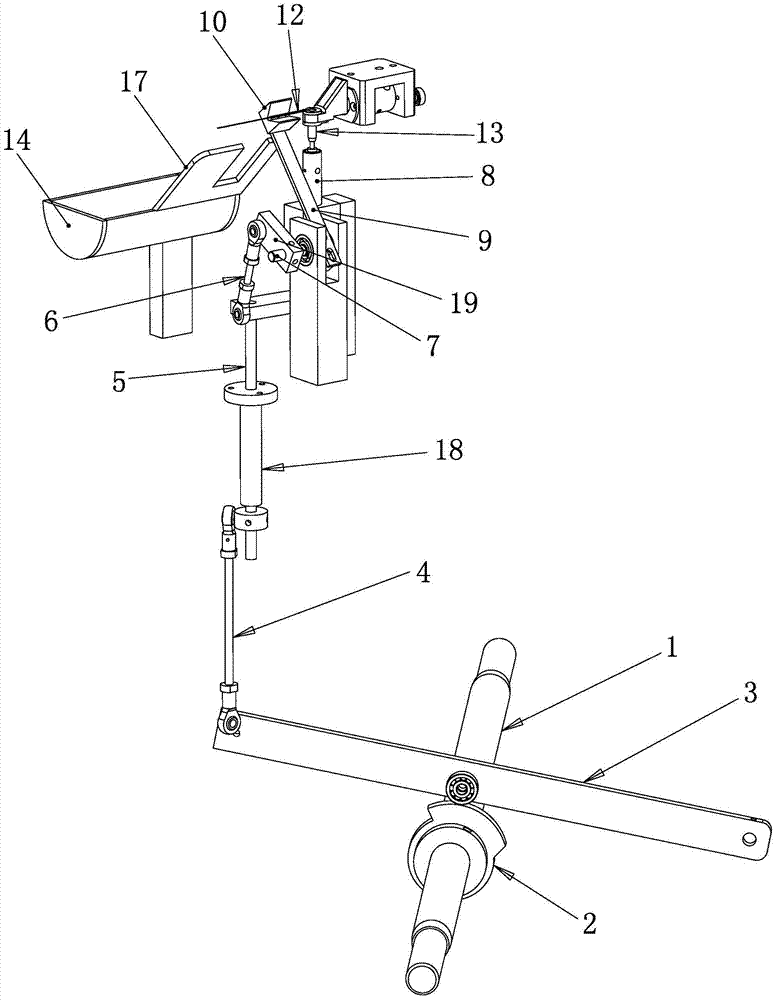

[0026] Example: see Figure 1~3 As shown, an acupuncture needle automatic winding machine unloading mechanism, a needle taking box 11 is fixed on the frame of the winding machine; the turntable of the winding machine rotates around a vertical line, and a workpiece clamping device 13 is arranged on the outer periphery of the turntable , the workpiece clamping device 13 clamps the acupuncture needles 12; the unloading mechanism is used to unload the acupuncture needles 12 from the workpiece clamping device 13 and put them into the needle removal box 11; when the workpiece clamping device 13 is used by a The pressing rod 8 acts when pressing upwards vertically to loosen the clamping of the acupuncture needle 12. The unloading mechanism includes a driving shaft 1, which rotates under the drive of the driving device, and the driving shaft 1 passes through a The reciprocating linear transmission mechanism drives and connects the pressing rod 8 to drive the pressing rod 8 to reciproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com