Method for optimizing shape of machined chamfer

A technology of mechanical processing and chamfering, which is applied in the field of optimizing the shape of mechanical processing chamfering, which can solve the problems of scratching the corresponding parts and not solving the parts well, so as to improve the appearance of parts, improve the assembly quality and meet the design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

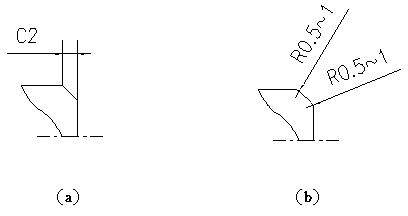

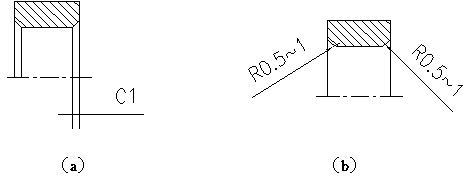

[0021] Such as figure 1 (a) to image 3 (b) The method for optimizing the chamfer shape of mechanical processing, using numerical control programming means to optimize the smooth transition of the chamfer of the outer diameter C2 of the shaft part or the sharp edge of the C1 chamfer of the inner hole of the disc part, including The steps are as follows: A. Carry out CNC programming in advance according to the design requirements; B. Use a CNC lathe to process the parts that need chamfering to the outer diameter C2 chamfering of shaft parts or the inner hole C1 chamfering of disc parts; C. 1. Round the two sharp edges of each chamfer processed above, and process two arcs with R0.5~1.

[0022] When CNC lathes are used to process shaft or disk parts, one-time forming can be achieved, that is, chamfers and sharp edge rounding can be processed by CNC programming in one too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com