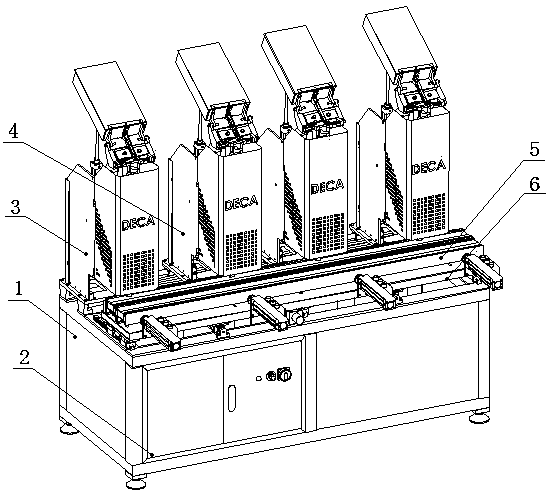

Double multi-handpiece full-automatic screw fastening machine

A multi-head, fully automatic technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity of workers and low processing efficiency, and achieve the problem of bearing capacity, simplifying equipment structure, improving The effect of using reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

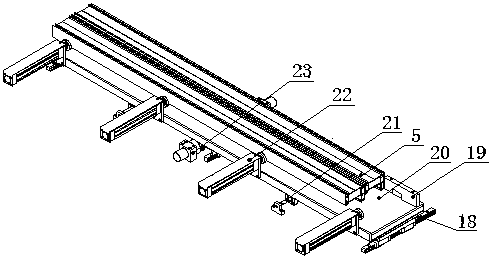

[0018] The present invention comprises a bed 1, an electric control box 2, a mobile workbench 6 and at least 2 machine heads, the machine heads are arranged above the bed 1, and the electric control box 2 is fixed inside the bed 1 below, for Control each logical action of the machine head.

[0019] One of the two heads is a movable head 4, and the other is a fixed head 3, and the movable head 4 and the fixed head 3 have the same structure.

[0020] The fixed machine head 3 is fixed on the top of the bed 1 with screws.

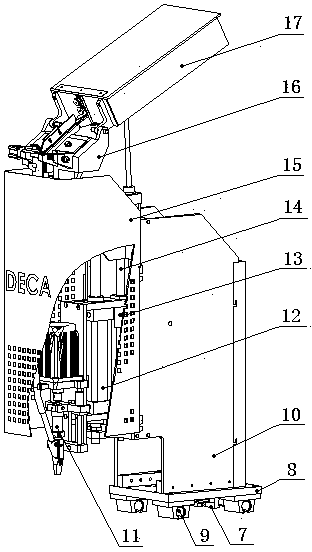

[0021] The movable head 4 is arranged on the top of the bed 1 through the bottom slider 9 and the guide rail fixed on the bed 1, and is arranged at intervals with the fixed head 3. The movable head 4 can move according to the size requirements of the processed profile through the guide rail.

[0022] The bottom of the movable nose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com