A device and method for removing volatile content of fusible fluorine-containing resin

A technology for fluorine-containing resin and volatile matter, which is applied in the field of devices for rapidly removing volatile matter from fusible fluorine-containing resin, can solve the problems of high labor intensity in intermittent operation, poor workplace environment, low drying and devolatilization efficiency, etc. The effect of increasing drying output, reducing drying energy consumption, and improving drying devolatilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

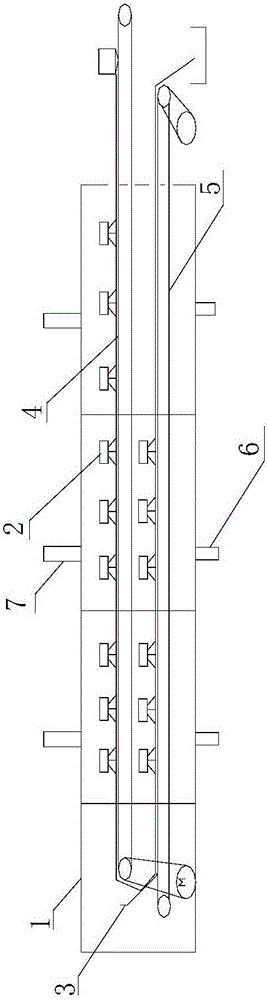

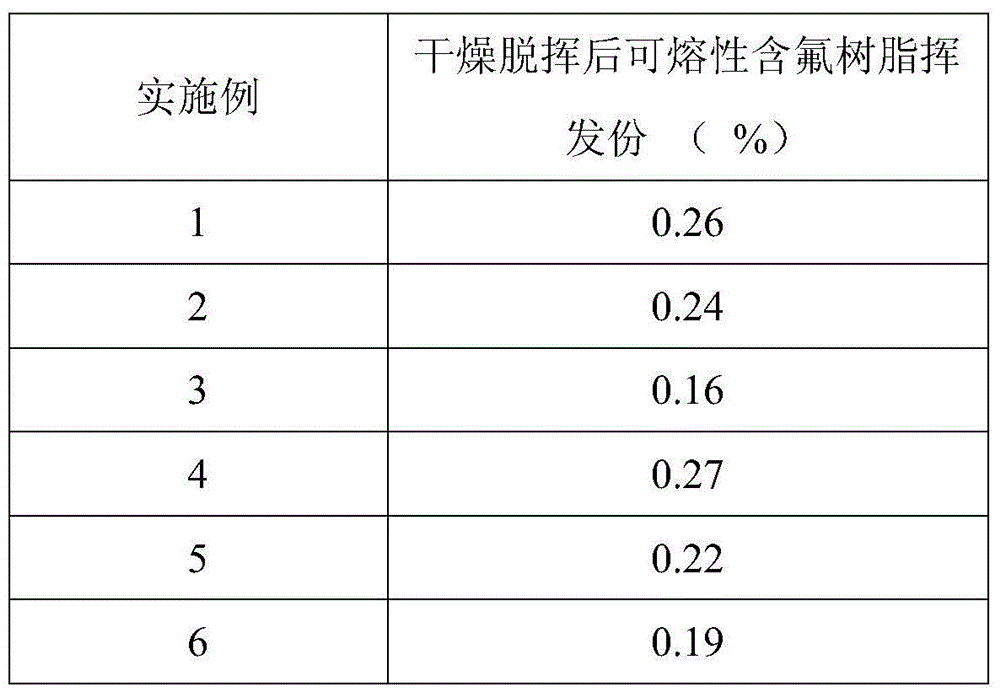

[0030] The box body 1 is rectangular (length 4m, width 2m, height 1.5m, made of stainless steel 304), the upper part of the feeding conveyor belt 4 is provided with six far-infrared directional radiation heaters 2 with a distance of 0.2m, and the discharge conveyor belt 5 The upper part is provided with four far-infrared directional radiation heaters 2 with a distance of 0.2m. The temperature of the far-infrared directional radiation heaters 2 is set at 290°C. Both the feed conveyor belt 4 and the discharge conveyor belt 5 are 60-mesh stainless steel wire Conveyor belt, add 5cm thick polyperfluoroethylene propylene (FEP) resin particles on the feed conveyor belt 4, the FEP resin is continuously transported into the box body 1 by the feed conveyor belt 4 at a rate of 20m / min, The directional radiation heater 2 heats and dries to remove volatile matter; 3The hot air with a temperature of 100°C is introduced at a wind speed of / min, and at the same time, the waste gas containing ...

Embodiment 2

[0032] The box body 1 is cylindrical (length 4m, diameter 1.5m, made of stainless steel 304L), and the upper parts of the feeding conveyor belt 4 and the discharging conveyor belt 5 are respectively provided with five far-infrared directional radiation heaters 2 with a spacing of 0.3m. Set the temperature of the far-infrared directional radiation heater 2 to be 200°C, the feed conveyor belt 4 and the discharge conveyor belt 5 are both 60-mesh stainless steel wire conveyor belts, and 4cm thick polyperfluoroethylene propylene is added to the feed conveyor belt 4 (FEP) resin particles, the FEP resin is continuously transported into the box body 1 at a rate of 10m / min through the feed conveyor belt 4, and is heated and dried by the far-infrared directional radiation heater 2 to remove volatile matter; simultaneously through the hot air inlet pipe 6 2m into box 1 3 The hot air with a temperature of 80°C is introduced at a wind speed of / min, and at the same time, the waste gas cont...

Embodiment 3

[0034] The box body 1 is rectangular (length 4m, width 2m, height 1.5m, made of stainless steel 304L), and the upper parts of the feeding conveyor belt 4 and the discharging conveyor belt 5 are respectively provided with four far-infrared directional radiation heaters with a distance of 0.4m 2. Set the temperature of the far-infrared directional radiation heater 2 to 220°C. The feed conveyor belt 4 and the discharge conveyor belt 5 are both 60-mesh stainless steel wire conveyor belts. Add 3cm thick ethylene-three Chlorofluoroethylene (ECTFE) resin particles are continuously conveyed into the box body 1 through the feeding conveyor belt 4 at a rate of 10m / min, and are heated and dried by the far-infrared directional radiation heater 2 to remove volatile matter; The inlet pipe 6 goes into the box body 1 at a distance of 3m 3 The hot air with a temperature of 70°C is introduced at a wind speed of / min, and at the same time, the waste gas containing volatile components is discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com