Graph printing injection molding method

A technology of injection molding and graphics, applied in the direction of coating, etc., can solve the problems of scratches, affecting the appearance, waste and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

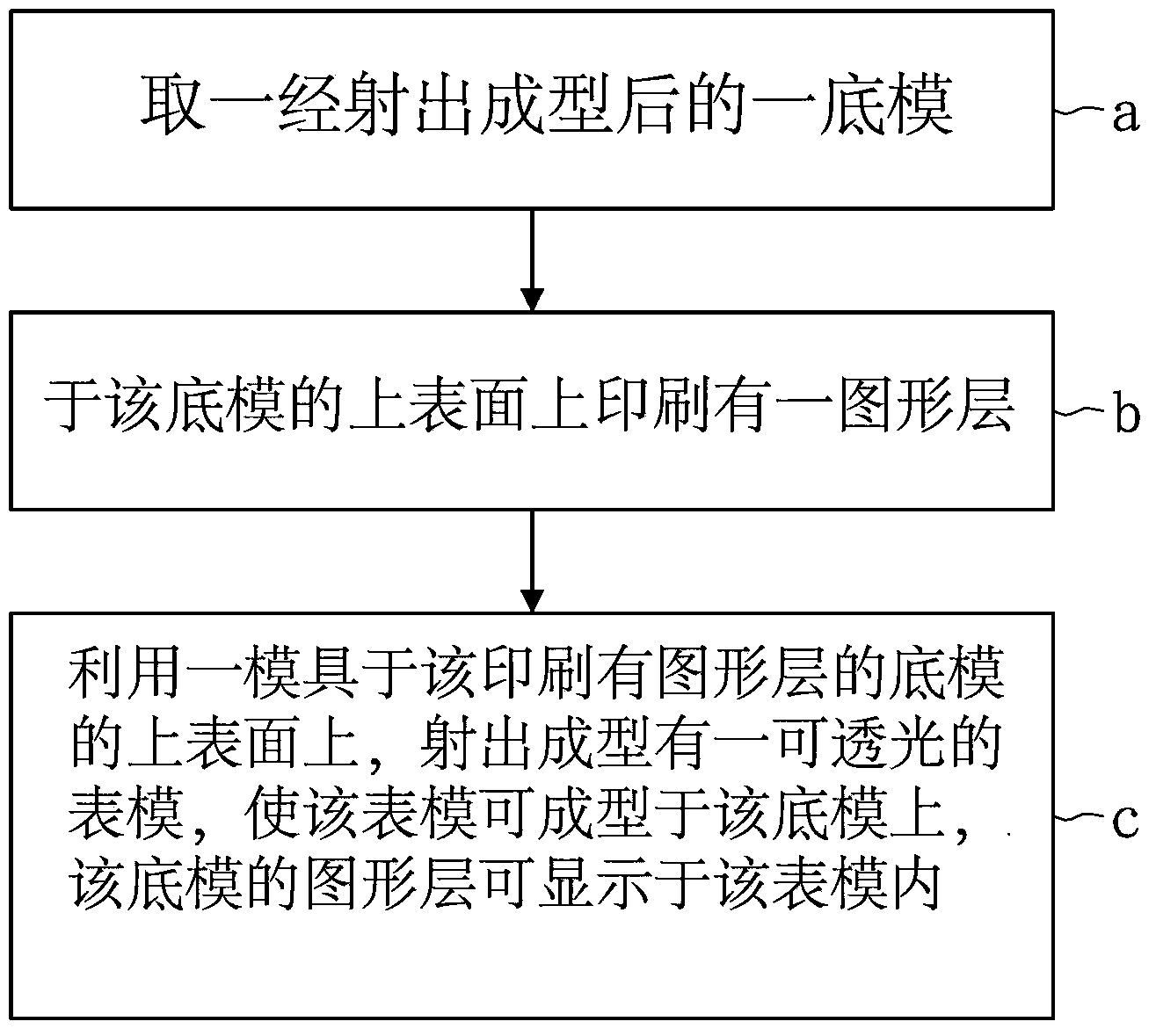

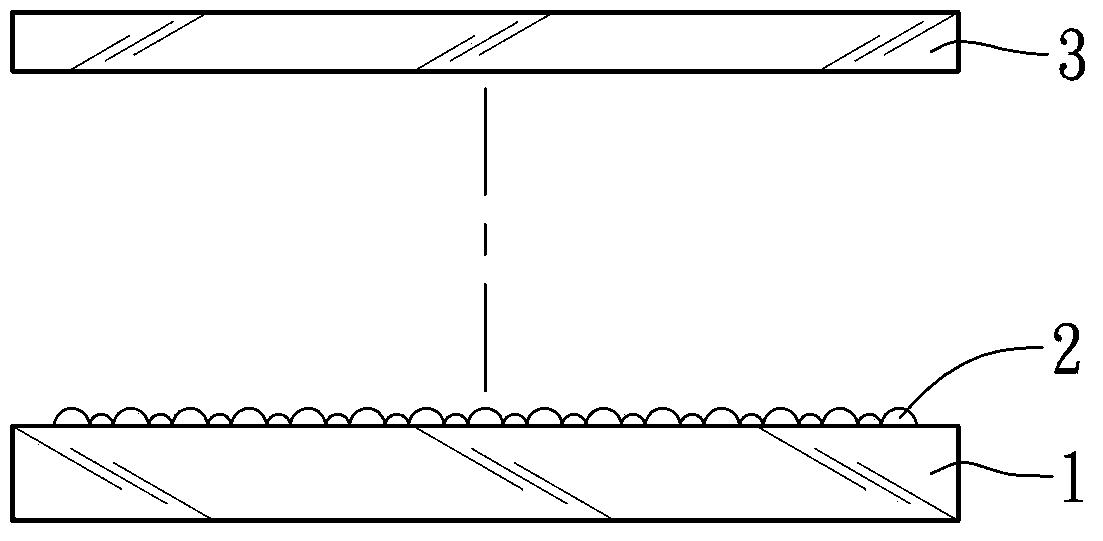

[0017] Please refer to Figures 1-3, which is an embodiment of a graphic printing injection molding method of the present invention, which includes the following steps:

[0018] Step a: Take a bottom mold 1 after injection molding;

[0019] Step b: printing a graphic layer 2 on the upper surface of the bottom mold 1;

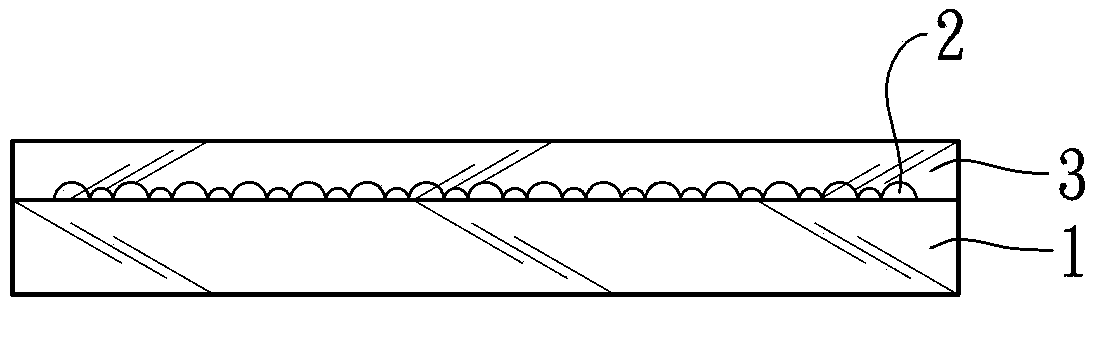

[0020] Step c: using a mold on the upper surface of the bottom mold 1 printed with the graphic layer 2, injection molding a light-permeable surface mold 3, so that the surface mold 3 can be molded on the bottom mold 1, and the bottom mold The graphic layer 2 of the mold 1 can be displayed in the surface mold 3 .

[0021] In practice, the bottom mold 1 is transparent or opaque, and the graphic layer 2 includes patterns or characters.

[0022] In this way, as shown in Figures 2 and 3, after the surface mold 3 is directly injection-molded on the bottom mold 1, a finished product can be formed, and the graphic layer 2 can pass through light as if it is wrapped in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com