Adjustable press combining frame mechanism

A combined frame and press technology, which is applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems that the sliders cannot be continuous and the integration performance is low, so as to overcome the trouble of adjustment, high integration performance and unification Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

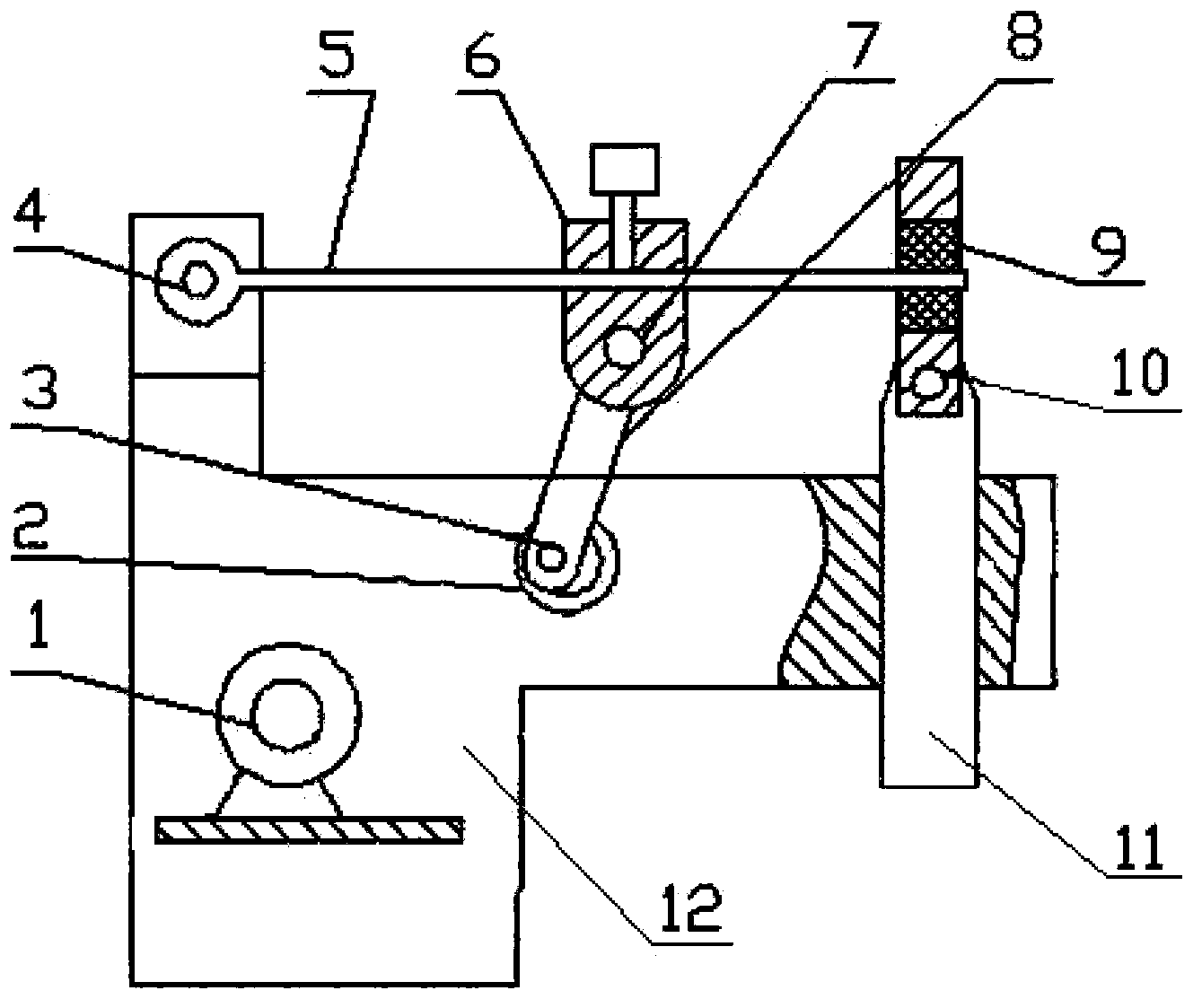

[0009] The combined frame mechanism has a combined frame body (12), a motor (1) is installed at the lower end of the combined frame body (12), and a driven pulley (2) and an eccentric shaft (3) are installed in the middle of the combined frame body (12). One end of the connecting rod (8) is hinged with the passive pulley (2) through the eccentric shaft (3), and the other end is hinged with the adjustment seat (6) through the movable pin (7), and an adjustment plate is installed on the adjustment seat (6) (5), one end of the adjustment plate (5) is connected with a positioning pin (4), and the other end is installed in the shaft hole of the pin shaft (10) through a silicone pad (9), and a slider ( 11), the slider (11) is hinged above the pin shaft (10) through the combined frame body (12).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com