Decorative film adhered on surface of printed matter and manufacturing method thereof

A production method and printing technology, applied in the direction of special decorative structures, decorative arts, chemical instruments and methods, etc., can solve problems such as prone to defective products, poor visual effects, high requirements, etc., and achieve good visual effects, smooth pattern edges, Easy to apply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

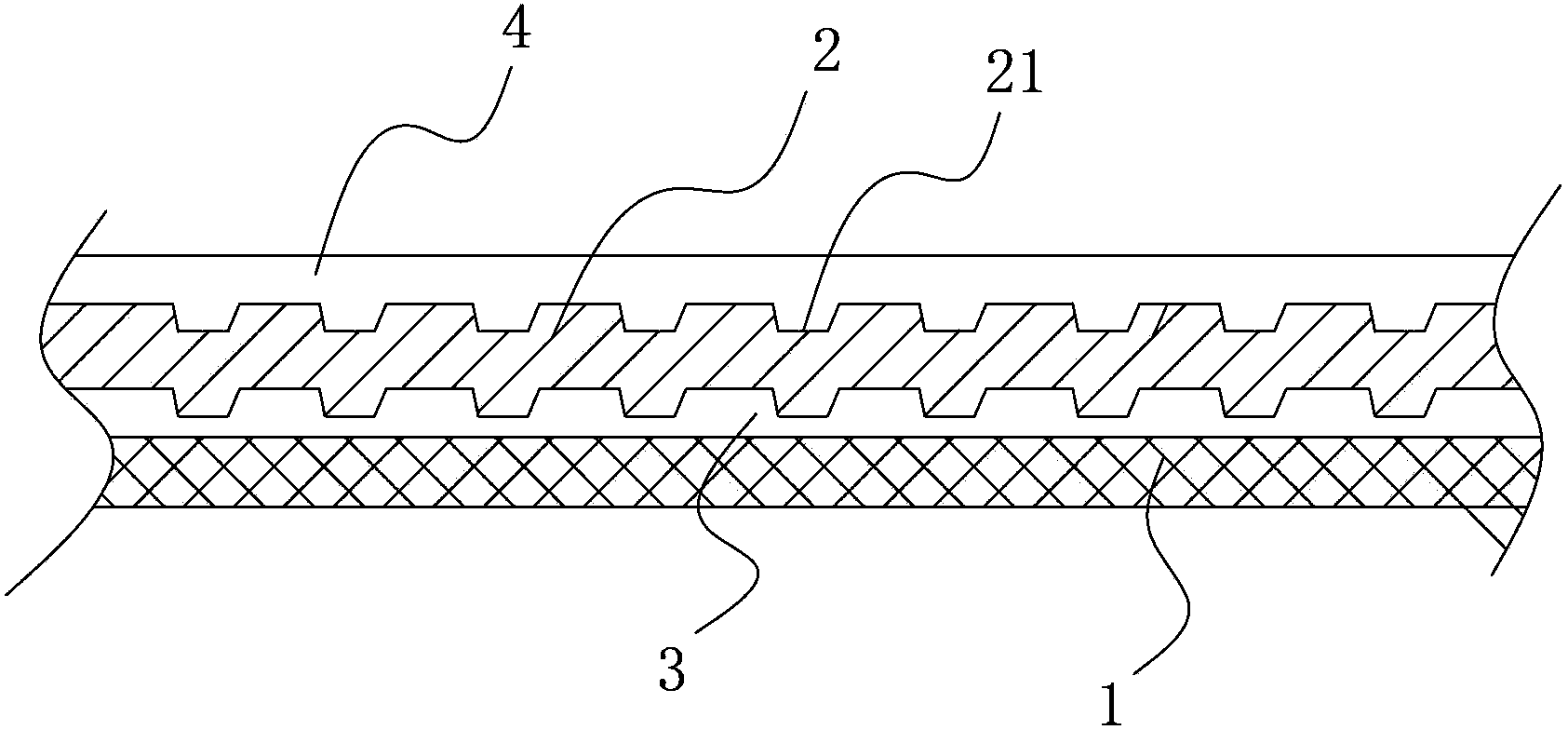

[0024] Such as figure 1 As shown, a decorative film of the present invention that is pasted on the surface of a printed matter includes: a paper substrate layer 1 , a color layer 3 , a plastic film 2 and a pattern layer 4 . Specifically, the surface of the plastic film 2 is pressed with regularly arranged concave holes 21. The shape of the concave holes 21 is mainly circular or similar to a circle with a diameter of no more than 0.1 mm, and some squares and / or squares with a side length of no more than 0.08 mm are also mixed. or rhombus, which makes the surface stress change of the plastic film more complicated, and it is not easy to cause regular damage. The density of the concave holes 21 is 130 to 175 per cm. The e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com