Handheld glass suction plate

A suction cup and glass technology, applied in the direction of transportation and packaging, manual conveying devices, etc., can solve the problems of low efficiency and danger, and achieve the effect of simple structure, high efficiency and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

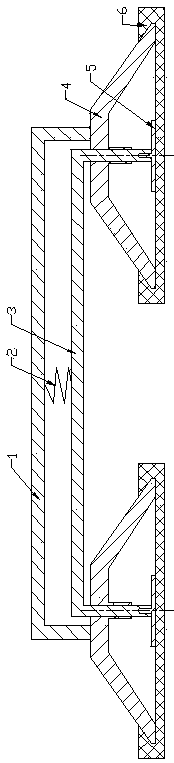

[0011] Such as figure 1 A kind of specific embodiment of the present invention shown, a kind of hand-held glass sucker comprises, handle 1, return spring 2, operating lever 3, sucker bracket 4, metal plate 5 and sucker 6; Two sucker brackets 4 are welded on the handle 1 both ends, the two ends of the operating rod 3 pass through the central hole of the suction cup bracket 4 and then connect with the metal disc 5, the suction cup 6 is installed under the suction cup bracket 4 and bonded with the metal disc 5, the return spring 2 is installed on the handle 1 and the operation between rods 3.

[0012] Working principle: When the staff is moving the glass, first stick the surface of the glass suction cup to the glass, then hold the handle and hold the operating rod tightly. As the operating rod moves up with the metal disc, a vacuum is formed in the center of the suction cup, thereby sucking tightly. The glass, and then the staff can carry the glass; during the carrying process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com