A conductive particle/silicone rubber pressure-sensitive material and its preparation method and application

A technology of conductive particles and pressure-sensitive materials, which is applied in the field of pressure-sensitive conductive rubber composite materials and its preparation, can solve the problems of limited strength variation range, weak positive pressure coefficient effect, single processing technology, etc., and achieve adjustable pressure-sensitive strength, The effect of strong repeatability and high pressure sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

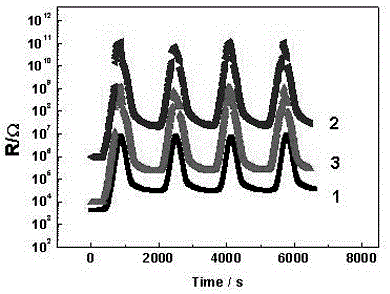

Embodiment 1

[0039] Take 2 parts by mass of aminopropyltriethoxysilane-modified carbon nanotubes (10-20nm, length 5-15μm) and 1 part by mass of montmorillonite and blend them in a beaker, add ethanol (25 parts by mass ) into a paste, ultrasonicated for 20 minutes (ultrasonic probe power 100000 Hz), the filler and 100 parts of methyl vinyl silicone rubber (molecular weight 620,000, vinyl content 0.15wt%) were pretreated at room temperature with an open double-roller plasticizer. Mixing; the flake premix was placed in a vacuum oven at 60°C for 24 hours to remove the ethanol solvent; then the premix was placed in the chamber of a Haake torque rheometer, and blended for 30min at 150°C and 120rpm / min to obtain montmorillonite / The primary product of carbon nanotube compound filling silicone rubber mixture.

[0040]Add the vulcanizing agent double 2,5 (the amount is 1.2% of the mass of the initial mixture) to the prepared montmorillonite / carbon nanotube compound filled silicone rubber mixture, i...

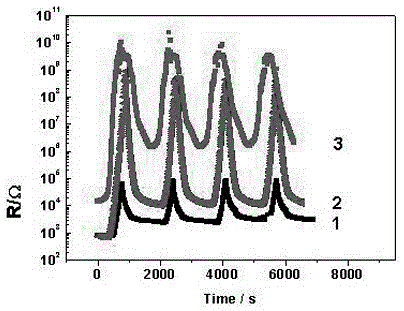

Embodiment 2

[0043] Take aminopropyltriethoxysilane-modified carbon nanotubes (10~20nm, length 5~15μm) 8 parts by mass and 3 parts by mass of montmorillonite and blend them in a beaker, add ethanol (70 parts by mass ) into a paste, and ultrasonicated for 40 minutes (ultrasonic probe power 1000Hz), the filler and 100 parts of methyl vinyl silicone rubber (molecular weight 620,000, vinyl content 0.15wt%) were pre-prepared at room temperature with an open double-roller plasticizer. Mixing; the flake premix was placed in a vacuum oven at 100°C for 8h, and the ethanol solvent was removed; then the premix was placed in the chamber of a Haake torque rheometer, and blended for 40min at 100°C and 80rpm / min to obtain montmorillonite / The initial product of carbon tube compound filling silicone rubber mixture.

[0044] Add the vulcanizing agent double 2,5 (the amount is 1.0% of the mass of the initial product of the montmorillonite / carbon tube composite filling silicone rubber mixture) to the prepare...

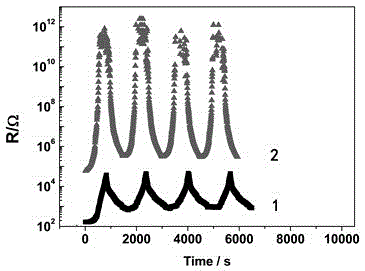

Embodiment 3

[0047] Take γ-methacryloxypropyltrimethoxysilane modified carbon nanofibers (diameter 150nm, length 5-10μm) 12 parts by mass and 1 part by mass of montmorillonite, blend them in a beaker, add ethanol (80 parts by mass) prepared into a paste, ultrasonicated for 30min (ultrasonic probe power 10000Hz), the filler and 100 parts of methyl vinyl silicone rubber (molecular weight 790,000, vinyl content 0.19wt% ) premixed at room temperature; the flake premix was placed in a vacuum oven at 40°C for 20 hours, and the ethanol solvent was removed; then the premix was placed in the chamber of a Haake torque rheometer, and blended at 100°C and 120rpm / min for 5min to obtain The initial product of montmorillonite / nanometer carbon fiber composite filling silicone rubber mixture.

[0048] Add vulcanizing agent bis-2,5 to the crude mixture prepared by 2wt% mass ratio, vulcanize for 10min in a flat vulcanizer at 170°C and 15MPa, and finally obtain a montmorillonite / nano-carbon fiber composite fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com