Transparent resistance type pressure sensor and application

A resistive pressure and sensor technology, applied in instruments, electrical digital data processing, computing, etc., can solve the problems of limited application, high force sensitivity, lack of high optical transparency, etc., to avoid false sensor touch, high pressure sensitivity , the effect of high optical transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

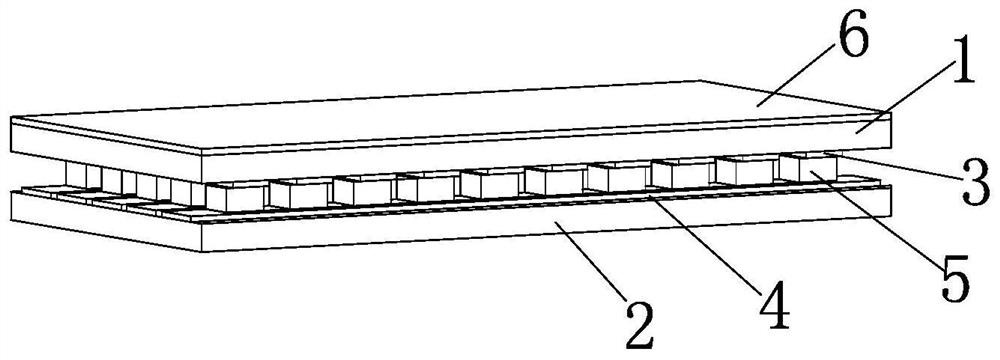

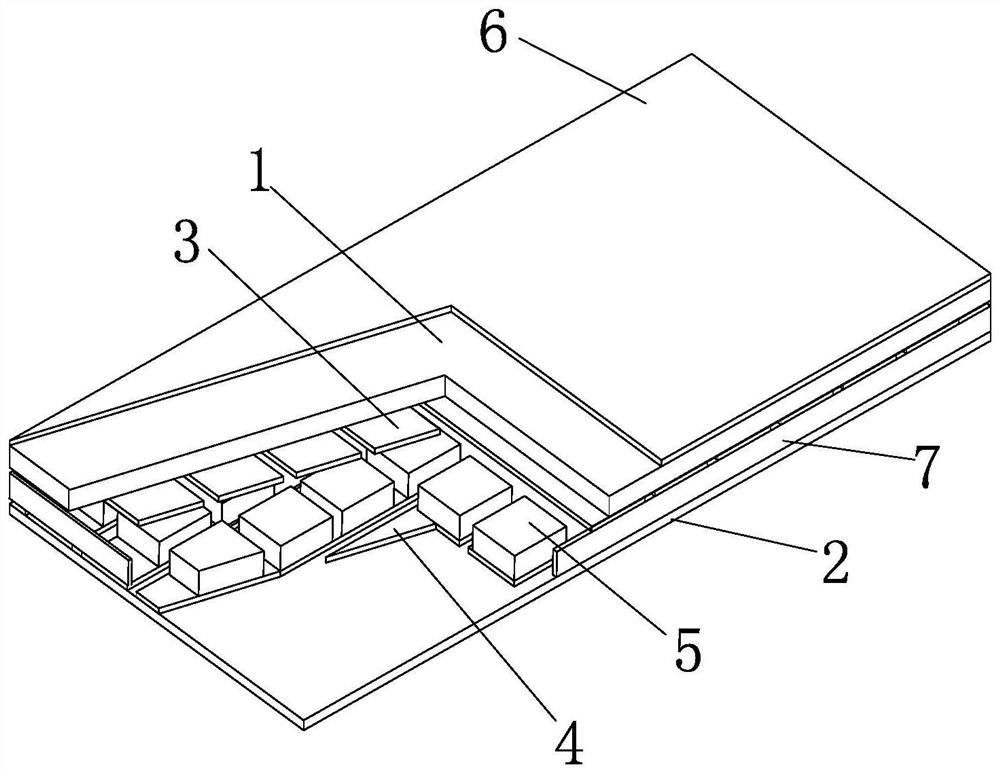

[0058] This embodiment discloses a transparent resistive pressure sensor, such as Figures 1 to 3As shown, it includes a pressure substrate 1 and a support substrate 2 arranged oppositely, and a plurality of pressure-sensitive units separated from each other are evenly distributed between the pressure substrate 1 and the support substrate 2; When the deformation occurs, the resistance changes, and when the pressure on one side of the pressure substrate 1 is removed, the resistance and shape of the pressure-sensitive unit return to the original state.

[0059] One side of the pressure substrate 1 is provided with strip-shaped first electrodes 3 arranged at intervals, and one side of the support substrate 2 is provided with strip-shaped second electrodes 4 arranged at intervals; the first electrodes 3 and the second electrodes 4 are The overlapping area of one of the first electrodes 3 and one of the second electrodes 4 is provided with a pressure-sensitive film 5 to form a pr...

Embodiment 2

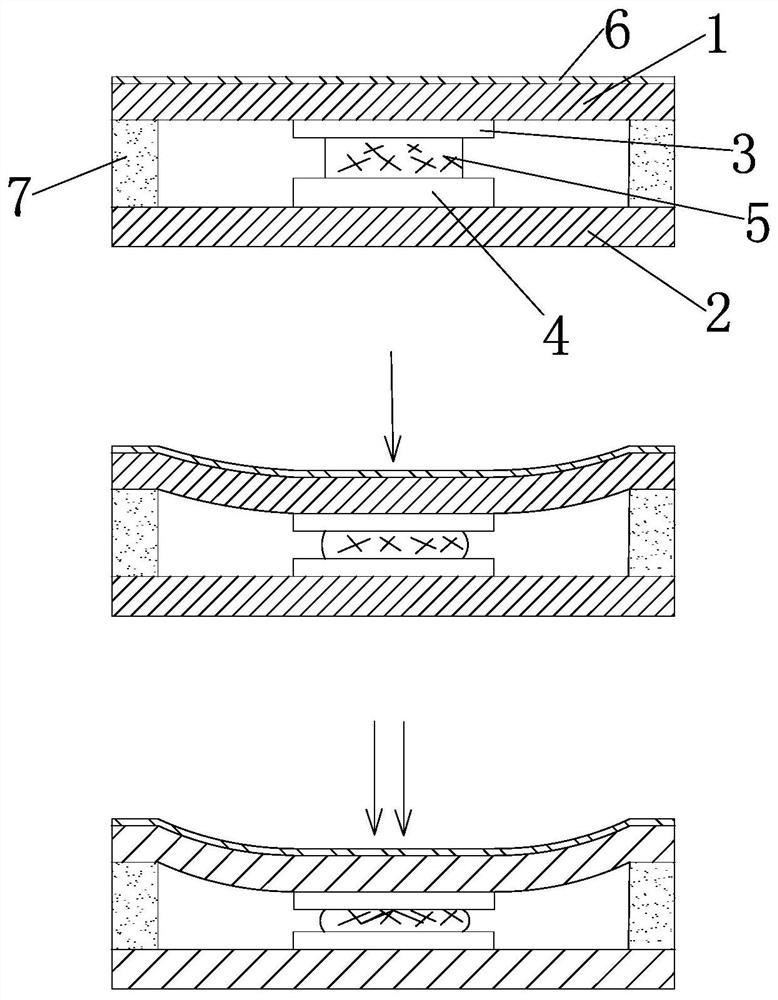

[0074] The main difference between this embodiment and embodiment 1 is detailed in Image 6 and Figure 7As shown, the pressure sensitive film 5 is located on the surface of the second electrode 4 of the pressure sensitive unit where it is located; when there is no pressure, there is an insulating gap between the pressure sensitive film 5 and the first electrode 3 .

[0075] The edges of each pressure-sensitive unit are provided with support members 7 .

[0076] The pressure sensitive film 5 in the pressure sensitive unit is attached to the surface of the second electrode 4 and there is an insulating gap between it and the first electrode 3 . When no external force is applied, no closed loop is formed between the first electrode 3 and the second electrode 4 , and the detectable resistance is infinite. Pressing the pressure substrate 1 lightly, the first electrode 3 bends downward and contacts the pressure sensitive film 5 . A closed circuit is formed between the two electro...

Embodiment 3

[0078] The main difference between this embodiment and embodiment 1 is as Figure 8 and Figure 9 As shown: the opposite sides of the pressure substrate 1 and the support substrate 2 are respectively provided with strip-shaped pressure-sensitive films 5 arranged at intervals; The pressure-sensitive film 5 on one side is arranged orthogonally; the pressure-sensitive film 5 on one side of each pressure substrate 1 and the pressure-sensitive film 5 on one side of a support substrate 2 overlap each other to form the pressure-sensitive unit;

[0079] When the pressure-sensitive film 5 is under pressure, it undergoes elastic deformation to cause a change in resistance, and when it is not under pressure, the shape of the pressure-sensitive film 5 returns to the initial state, causing the resistance to return to the initial state.

[0080] When one side of the pressure substrate 1 is not under pressure, there is an insulating gap between the pressure-sensitive film 5 on the side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com