Noniron finishing method for pure cotton fabric

A non-iron finishing, pure cotton fabric technology, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problems of poor wear resistance, large strength damage, etc., to achieve small impact, high strength retention, non-iron and anti-wrinkle effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Non-ironing finishing of pure cotton fabrics:

[0012] Pad the pure cotton fabric in the impregnating solution containing non-ironing finishing agent, the pressure is 2kg / cm 2 , with a liquid rate of 75%; dry the pure cotton fabric, iron it to shape; keep the temperature at 140°C for 2 hours.

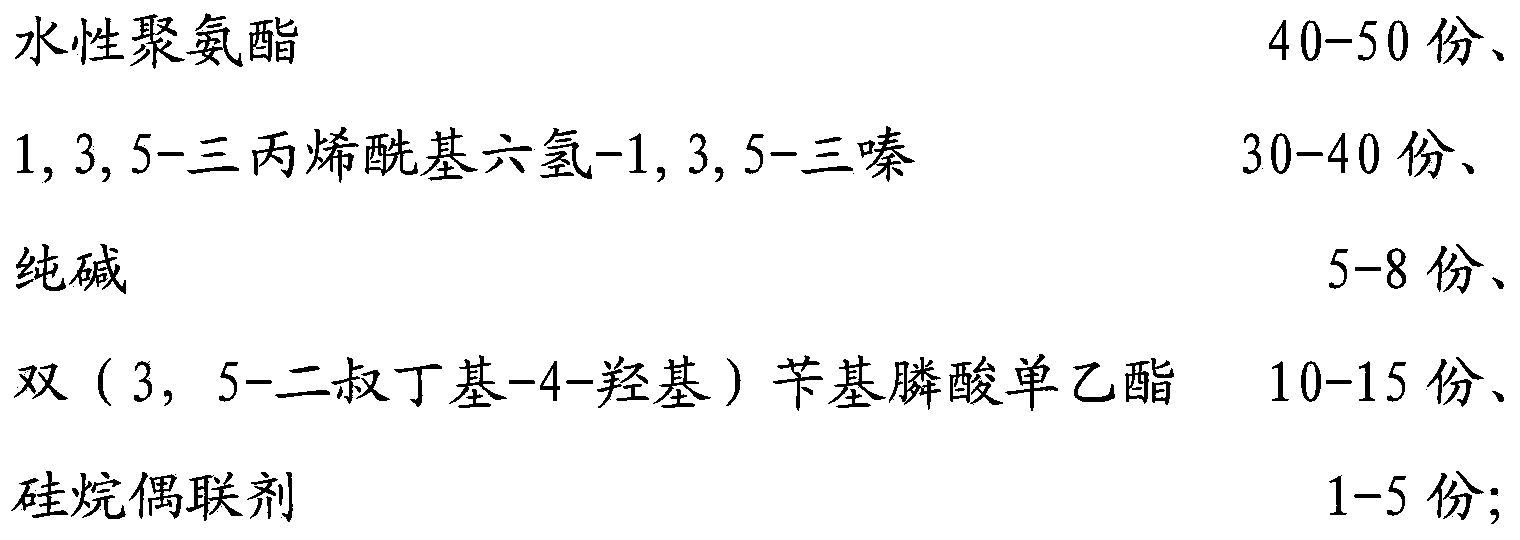

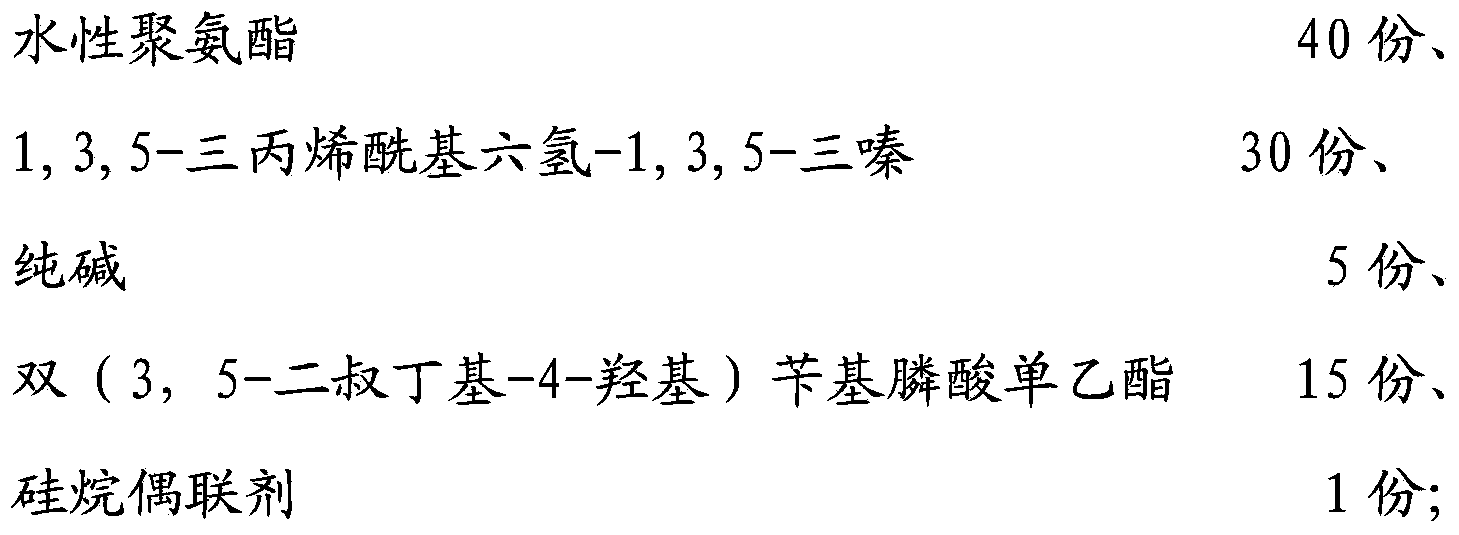

[0013] Non-ironing finishing agent:

[0014]

[0015] And add water to make an impregnation solution with a mass content of 15%.

[0016] The easy-care finishing agent is prepared by the following method: add 30 parts of 1,3,5-triacryloylhexahydro-1,3,5-triazine and 5 parts of soda ash into water, heat to 80-95°C, and then add Mix 40 parts of water-based polyurethane, 15 parts of monoethyl bis(3,5-di-tert-butyl-4-hydroxy)benzylphosphonate, and 1 part of silane coupling agent.

Embodiment 2

[0018] Non-ironing finishing of pure cotton fabrics:

[0019] Pad the pure cotton fabric in the impregnating solution containing non-ironing finishing agent, the pressure is 2.5kg / cm 2 , with a liquid retention rate of 80%; dry the pure cotton fabric, iron it to shape; keep the temperature at 150°C for 0.5 hours.

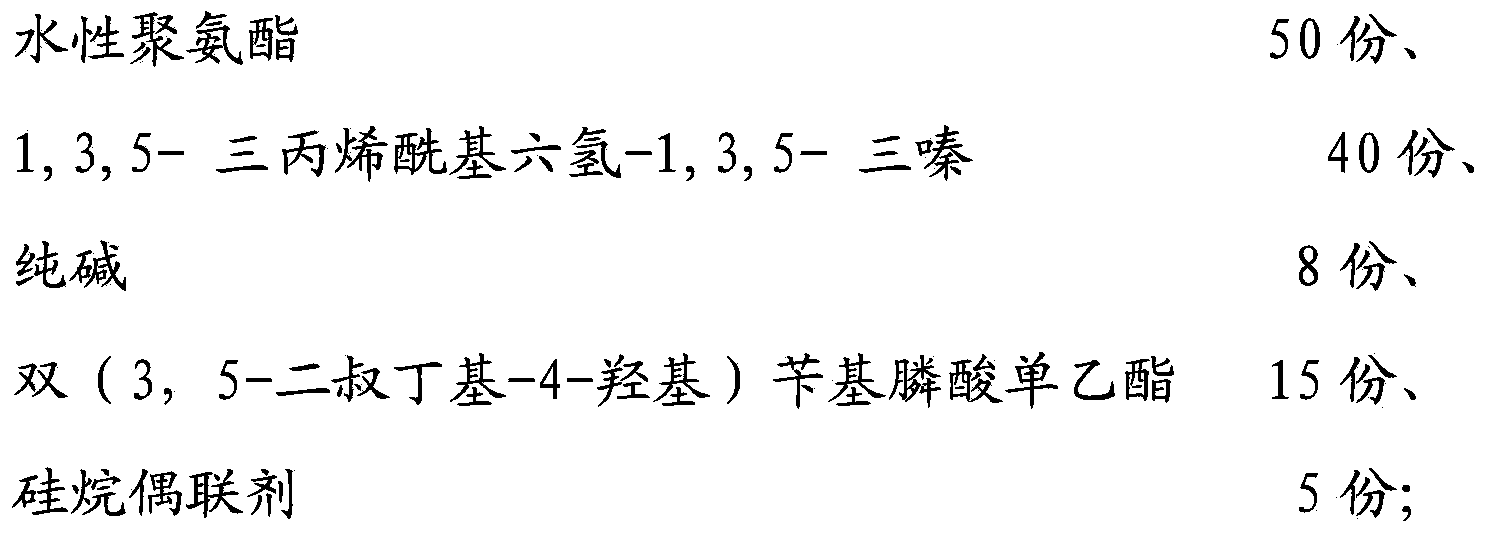

[0020] Non-ironing finishing agent:

[0021]

[0022] Add water to make an impregnating solution with a mass content of 20%.

[0023] The non-iron finishing agent is prepared by the following method: add 1,3,5-triacryloylhexahydro-1,3,5-triazine and 8 parts of soda ash into water, heat to 80-95°C, and then add water-based 50 parts of polyurethane, 15 parts of monoethyl bis(3,5-di-tert-butyl-4-hydroxy)benzylphosphonate, and 5 parts of silane coupling agent are mixed evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com