Internally-installed shutter rotation magnetic control device

A magnetic control device and louver technology, which is applied in door/window protection devices, shading screens, windows/doors, etc., can solve the problems of electric control device motor damage, built-in louver hollow glass failure, and irreparable problems, so as to prolong life, The effect that is conducive to the promotion of the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

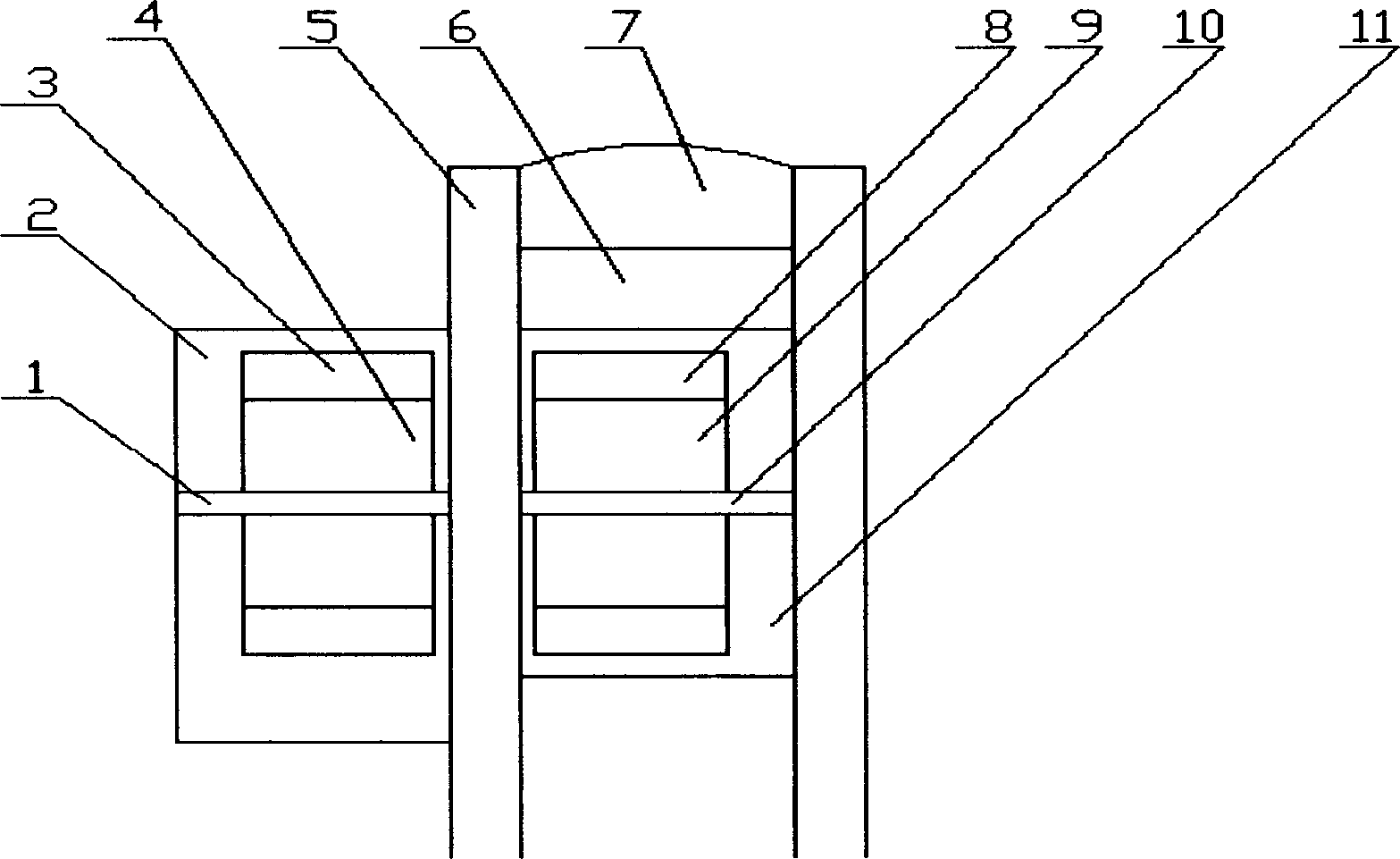

[0011] Such as figure 1 The illustrated example of the insulating glass is Example 1, figure 1 The middle and outer control device 2 is composed of the outer shaft 1, the outer rotor 4 and the outer magnet or iron material 3 on it, and the internal control device 2 is composed of the inner shaft 1, the inner rotor 4 and the inner magnet or iron material 3 on it. When the external magnet or iron object 3 rotates around the external shaft 1, the internal magnet 8 is also rotated around the internal shaft 10 due to the magnetic force acting on the internal magnet 8 through the glass 5, which drives the built-in louver lifting shaft to rotate to complete the built-in louver Lifting function.

Embodiment 2

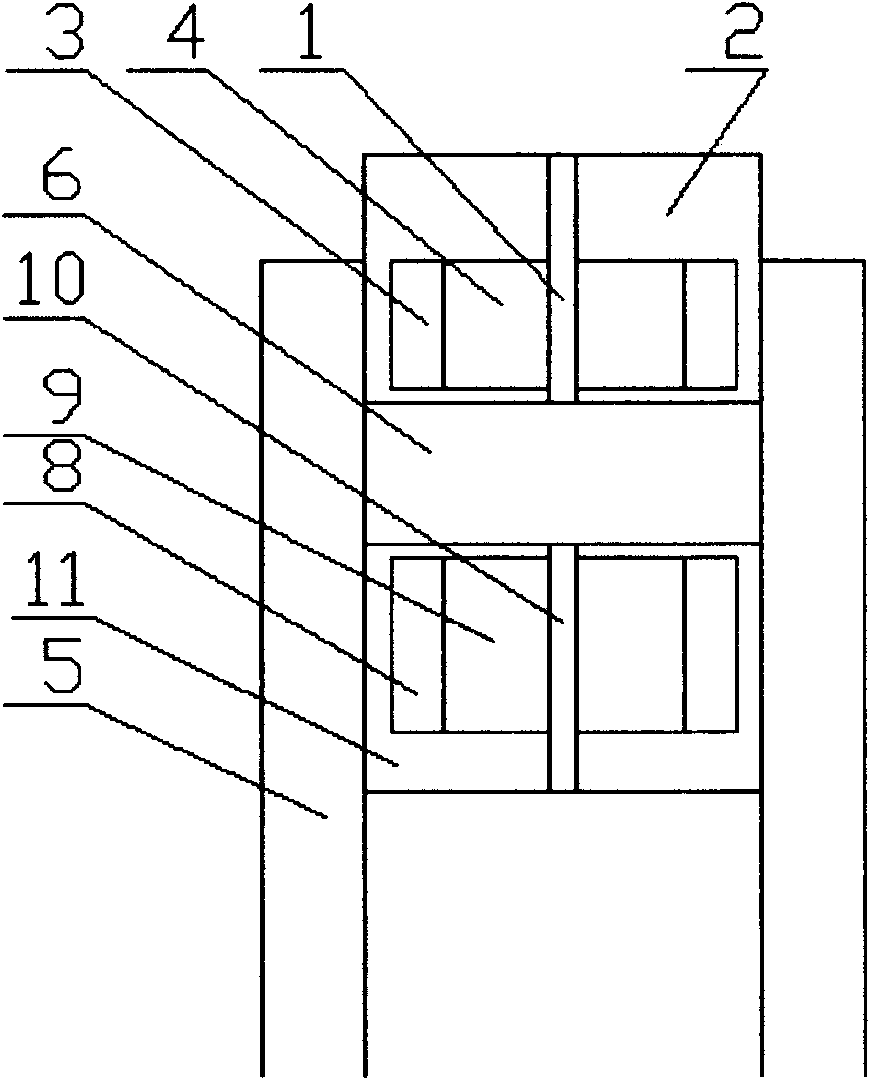

[0013] Such as figure 2 The embodiment of the spacer bar shown is embodiment 1. figure 1 The middle and outer control device 2 is composed of the outer shaft 1, the outer rotor 4 and the outer magnet or iron material 3 on it, and the internal control device 2 is composed of the inner shaft 1, the inner rotor 4 and the inner magnet or iron material 3 on it. When the external magnet or iron object 3 rotates around the external shaft 1, the internal magnet 8 is also rotated around the internal shaft 10 due to the magnetic force acting on the internal magnet 8 through the spacer 6, thus driving the built-in louver lifting shaft to rotate to complete the built-in Louver lifting function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com