Compact and rapid tubing hanger

A kind of tubing hanging and fast technology, which is applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problem that the four-way can not achieve full diameter, and achieve the effect of improving operation efficiency and saving operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

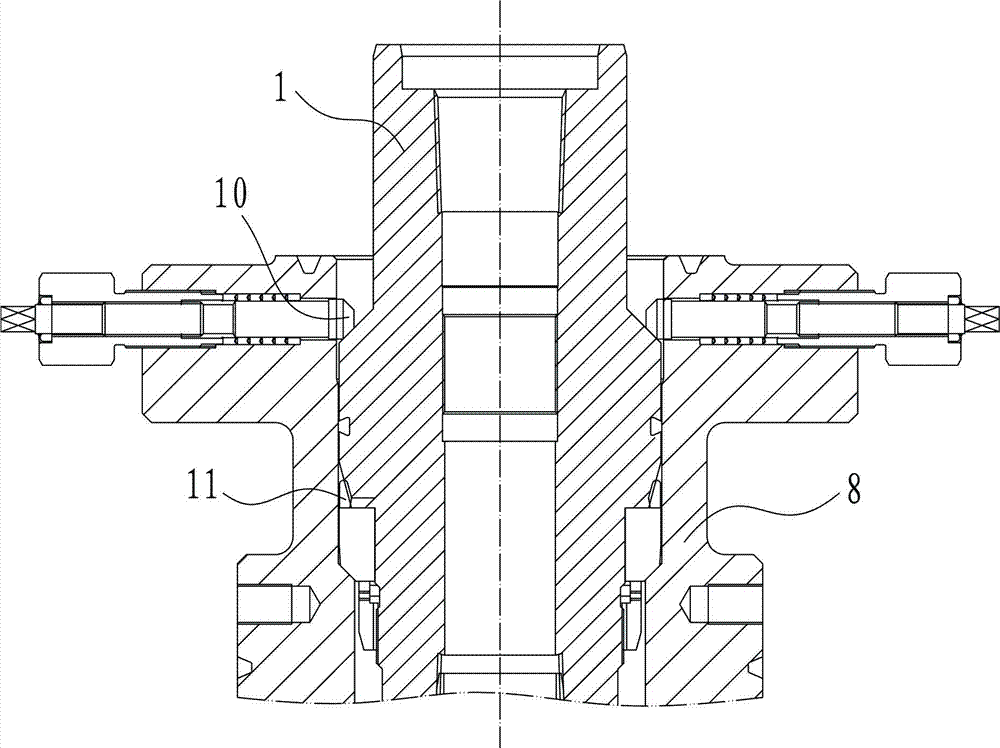

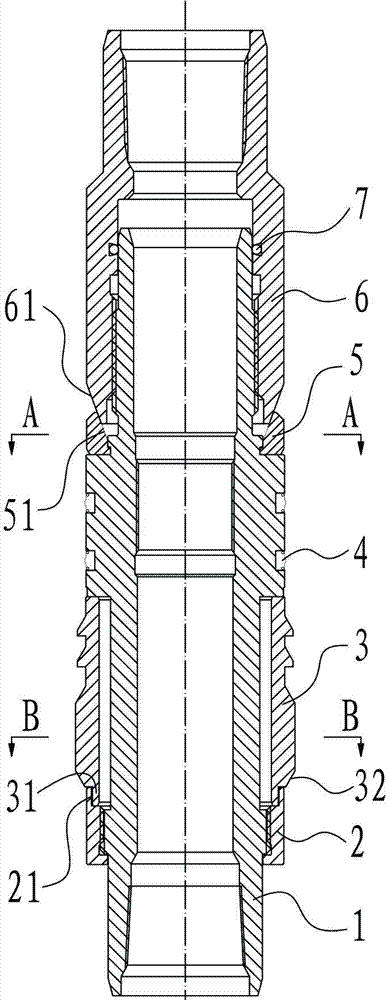

[0027] refer to figure 2 with Figure 5 , the present invention includes a mandrel-type oil pipe hanger body 1 and a four-way body 8, and the oil pipe hanger body 1 is seated and hung in the inner cavity of the four-way body 8.

[0028] The lower end of the mandrel type tubing hanger body 1 is covered with a support ring 3, and the pipe hanger body 1 at the lower end of the support ring 3 is provided with a threaded ring 2 through threaded connection, and the threaded ring 2 can hold the support ring 3 in the axial direction. fixed.

[0029] The upper end of the mandrel-type tubing hanger body 1 is covered with a locking ring 5, and the upper end of the locking ring 5 is provided with a sealing bag body 6 on the pipe hanger body 1 through threaded connection.

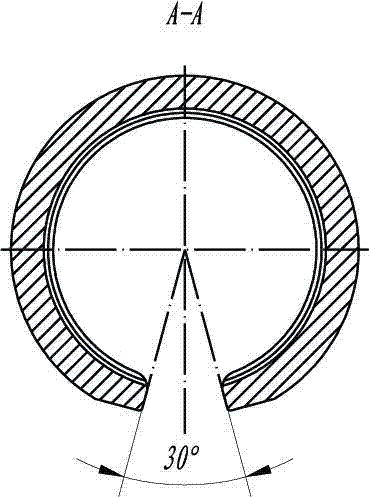

[0030] refer to image 3 with Figure 4 , the support ring 3 and the locking ring 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com