Uniform optical reflection method and round LED light source designing method

A LED light source and optical reflection technology, applied in the field of lighting, can solve the problems of high efficiency, poor uniformity, and large thickness of flat lighting, and achieve good reflection effects, good uniformity, and high light rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

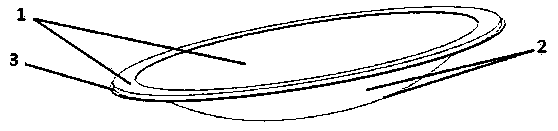

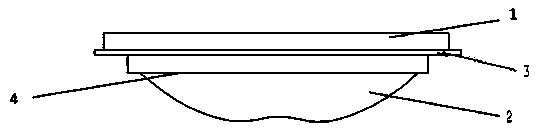

[0031] Such as figure 1 , figure 2 , Figure 4 and Figure 5 , the LED optical reflector 2 is a bowl-shaped structure with flanging, and the inner bottom of its curved reflective surface is provided with a circular protrusion, and the center of the LED light source 4 and the LED optical reflector 2 is located on the same axis .

[0032] The LED optical reflector 2 is connected with a circular frame-shaped mounting bracket 3, the LED light source 4 is arranged on the mounting bracket 3, and a heat sink is arranged on the mounting bracket 3, and the head of the LED light source 4 faces the LED optical The reflector 2 and the front of the LED optical reflector 2 are provided with a light-transmitting toughened glass guard plate 1 .

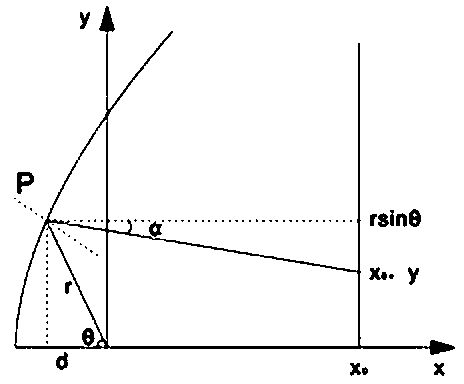

[0033] The LED light source of the present invention adopts the power type, the working voltage is 3V, the driving current is 350mA, the luminous flux is 100 lumens, and the divergence angle of the light source is 120°. The curved reflective su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com