A Method of Uniform Distribution of Machining Errors Based on Gradual Change of Tool Attitude

A machining error and cutting tool technology, which is applied in the field of tool path generation where the machining error is uniformly distributed through the gradual change of the tool attitude, can solve the problems of affecting the machining quality and the lack of consistency of the machine tool motion accuracy to the machining error, so as to avoid interference with the non-machined surface , Realize processing error and avoid the effect of over-cutting the processed surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] See Figure 8 , the present invention provides a method for uniform distribution of machining errors based on tool attitude gradients, taking the machining of a blade curved surface as an example, the specific implementation steps are as follows:

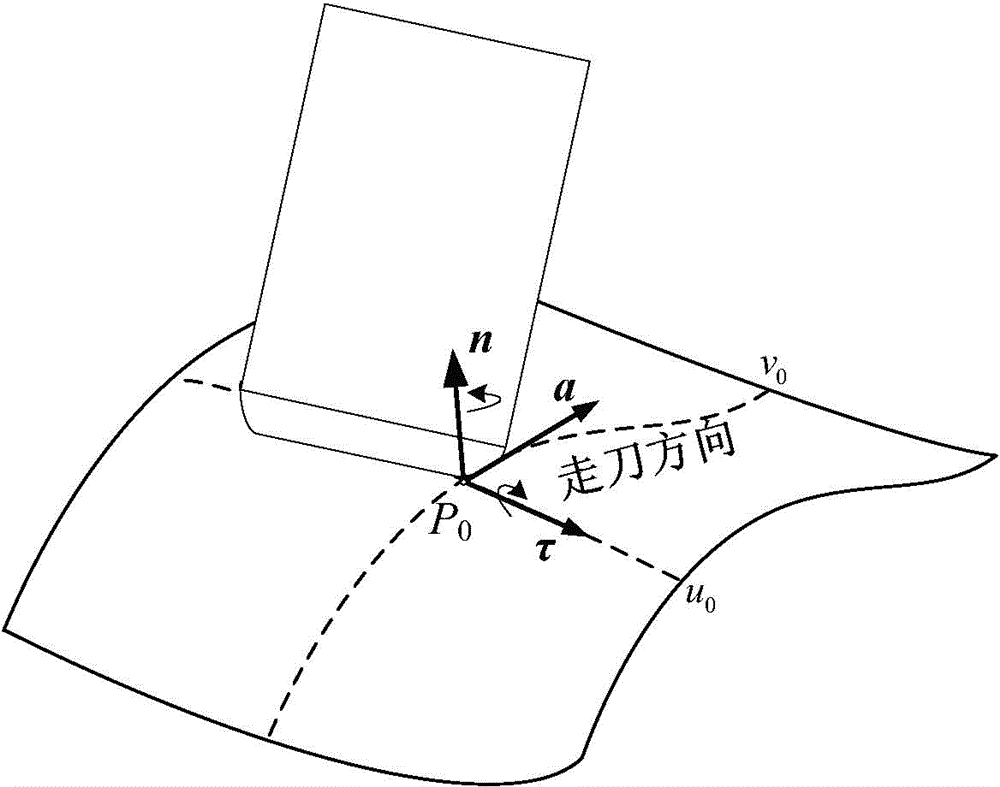

[0049] It is assumed that the tool is moved along the direction of the u parameter line, and the direction of the arrangement of the tool path is along the direction of the increase of the parameter v. The parameter domain to be processed on the surface is ((u min ,v min ), (u max ,v max )).

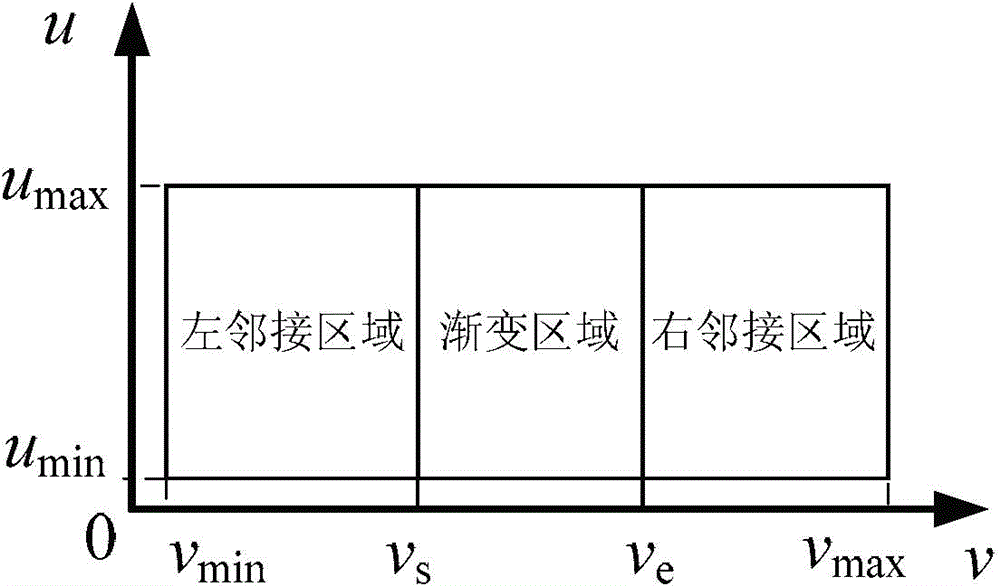

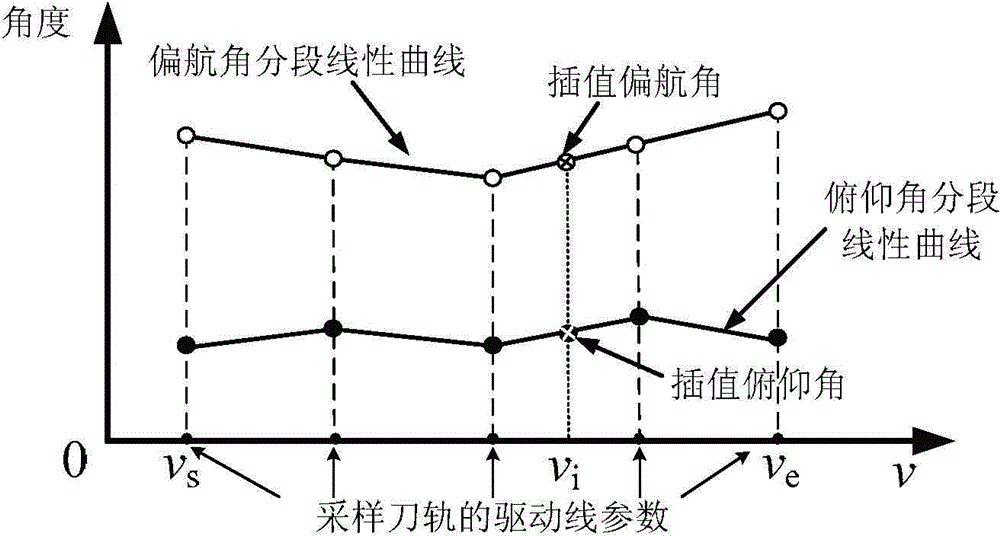

[0050] Step 1: Define a range on the surface as the tool path gradient area. like figure 2 As shown, the processing area of the surface is divided into the tool path gradient area (v s ,v e ) and the left and right adjacent regions (v min ,v s ) and (v s ,v max ).

[0051] Parameter description in this step: u min ,u max ,v min ,v max —The parameter range of the curved surface processing area, which are the minimum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com