Universal ZIF (Zero Insertion Force) connector bonding pad

A technology of pads and pad areas, applied in the direction of electrical connection of printed components, printed circuit components, etc., can solve the problems of inability to share, affect production efficiency, and the size of connector pads vary widely, so as to avoid redesign and improve production. Efficiency, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

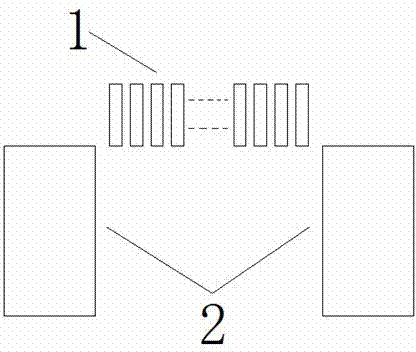

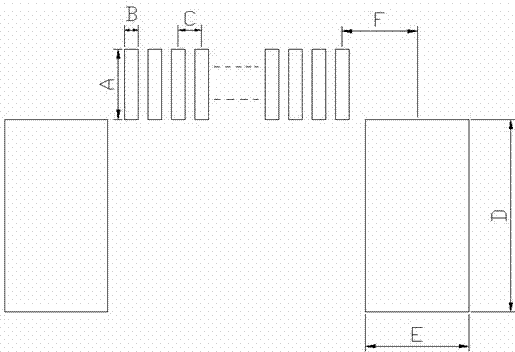

[0009] In order to understand the present invention more clearly, the present invention is described in detail below in conjunction with accompanying drawing: With reference to figure 1 and figure 2 A common ZIF connector pad includes a pin pad area and a fixed pad area, and several pin pads 1 are arranged in the pin pad area (the number of pin pads is determined according to needs, and the pin The number of pads is the same as the number of connector pins to be soldered), and is located on the upper part of the overall pad, and there are two square fixed pads 2 in the fixed pad area, and is located on the lower part of the overall pad, the overall pad Left and right symmetrical; the length A of each pin pad 1 in the pin pad area is set to 1.5mm, the width B is set to 0.3mm, and the center distance C between adjacent pin pads 1 is set to 0.5mm; The length D of the two square fixed pads 2 in the pad area is set to 4.1mm, and the width E is set to 2.2mm; The upper edges of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com