Twin-screw compressor pressure testing mechanism

A technology for pressure testing and compressors, which is applied in the direction of machines/engines, mechanical equipment, pump control, etc. It can solve the problems of high technical requirements for operation, cumbersome and complicated pressure testing structure of twin-screw compressors, and the inability to guarantee the normal operation of rotor meshing, etc. , to achieve accurate measurement, avoid machine modification design, and avoid the effect of sensor placement problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

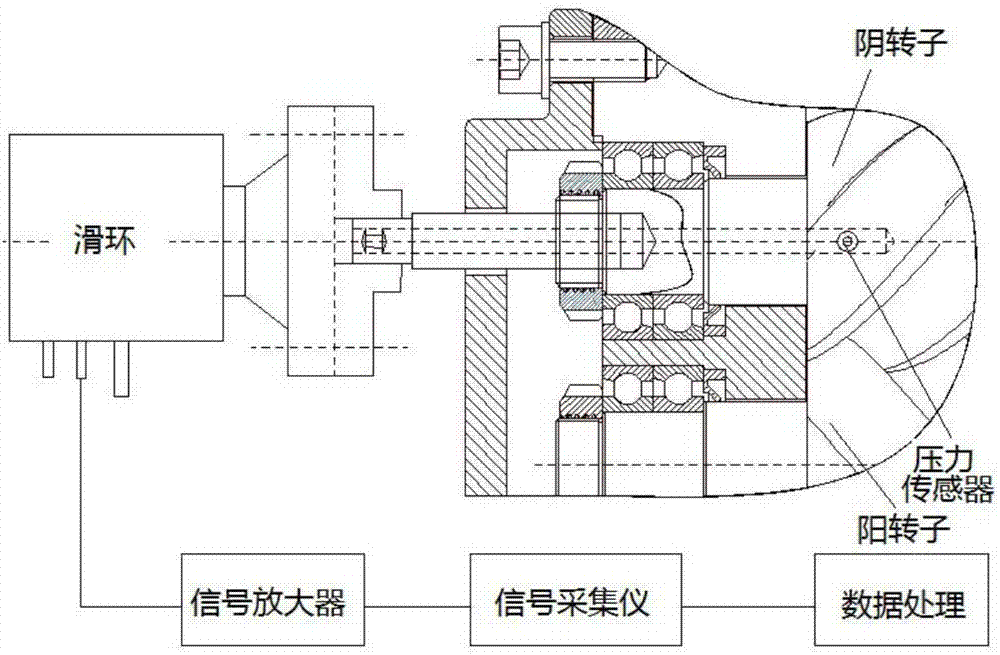

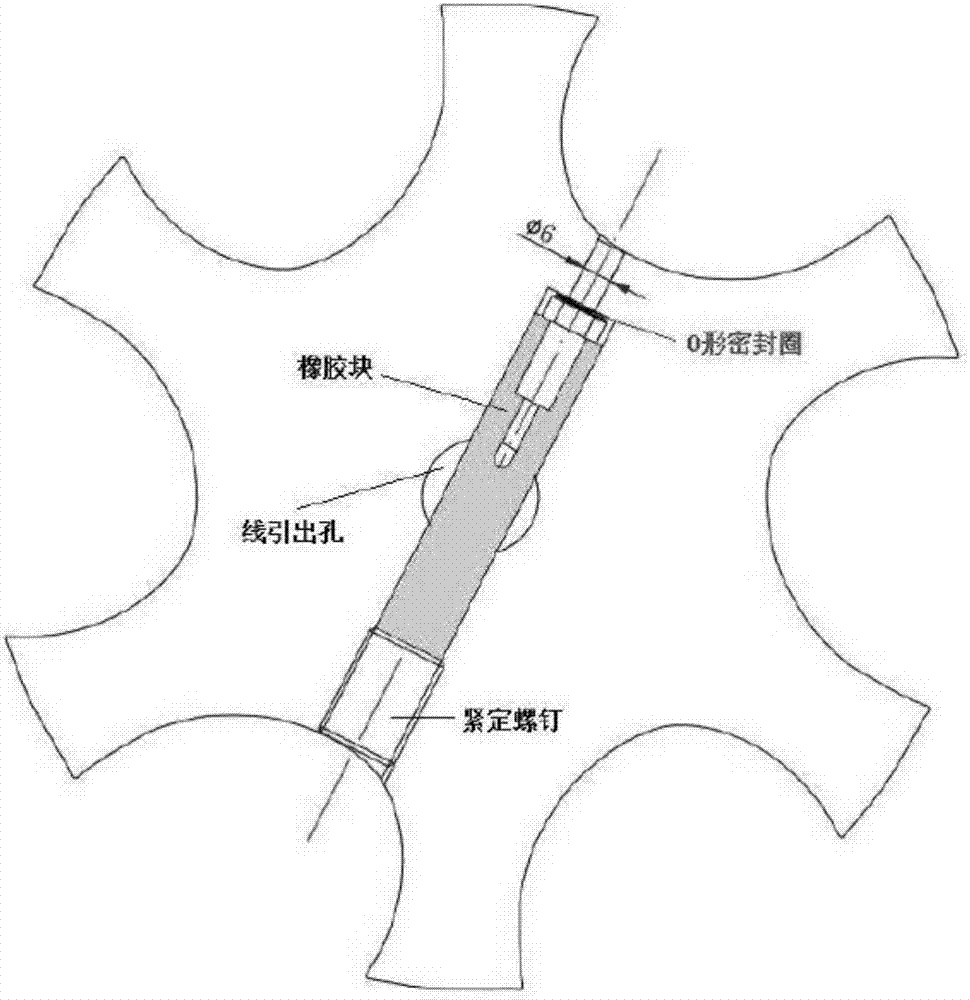

[0022] figure 1 Shown is the structural principle block diagram of the existing twin-screw compressor pressure testing mechanism, including the twin-screw compressor host, slip ring device, pressure sensor, signal amplifier, data acquisition card, etc. figure 2 Shown is the schematic diagram of the installation of the pressure sensor, which is installed at the bottom of the tooth groove near the exhaust end of the female rotor. The existing pressure test scheme requires secondary processing of the screw rotor, which requires high-precision machining of the rotor, which is easy to damage the integrity of the rotor tooth profile and reduce the operating strength of the rotor. The local maximum strength of the rotor after processing is reduced by 5%-10%. Moreover, the signal line and the power line need to be differentially connected through a special slip ring device, and the operation of the whole solution is difficult.

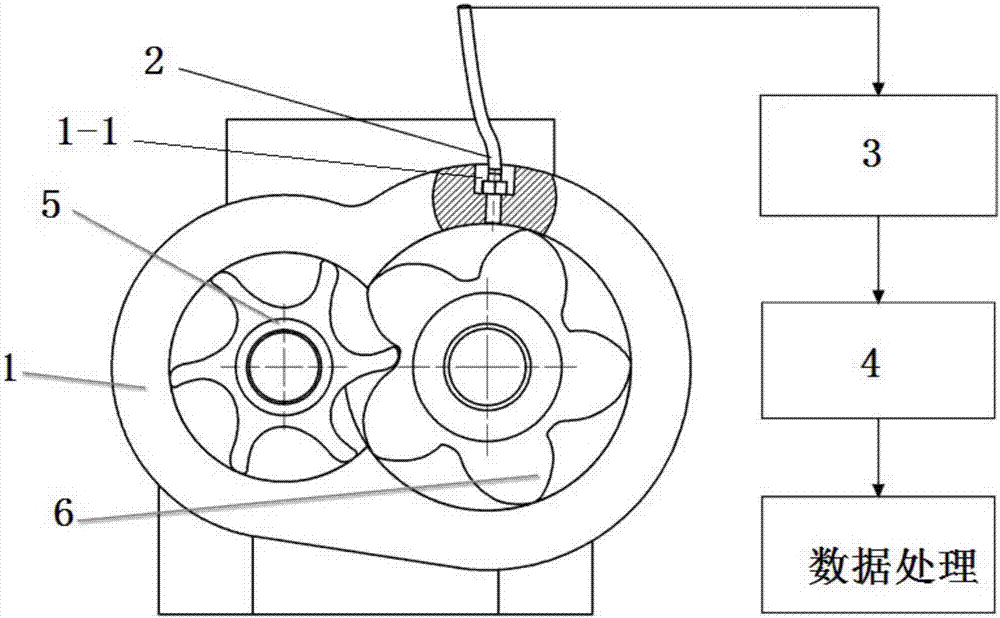

[0023] This embodiment discloses a twin-screw compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com