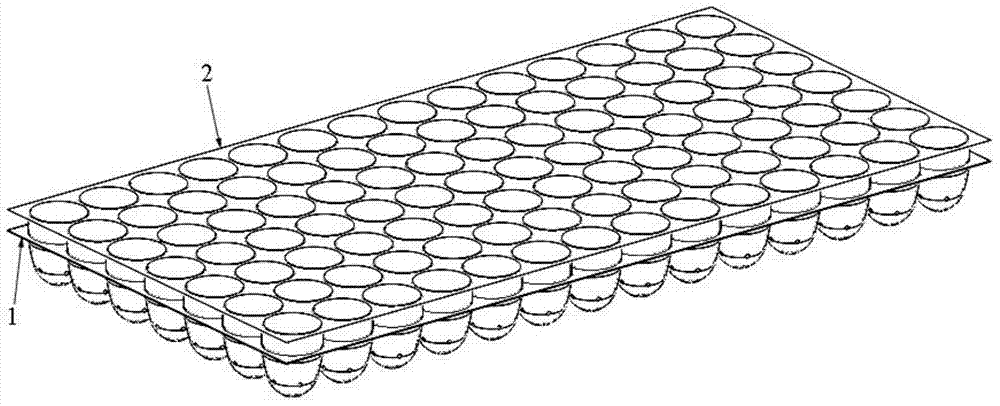

A kind of seedling raising tray and sowing method thereof

A technology of seedling trays and seedling substrates, applied in the fields of application, cultivation, agriculture, etc., can solve the problems that the coverage thickness and sowing depth cannot be unified, affect the response and absorption of seeds, affect the growth management of seedlings, and achieve the realization of water flow Maximize and work efficiently, improve the effect of easily penetrating the bottom, and reduce the labor rate of sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

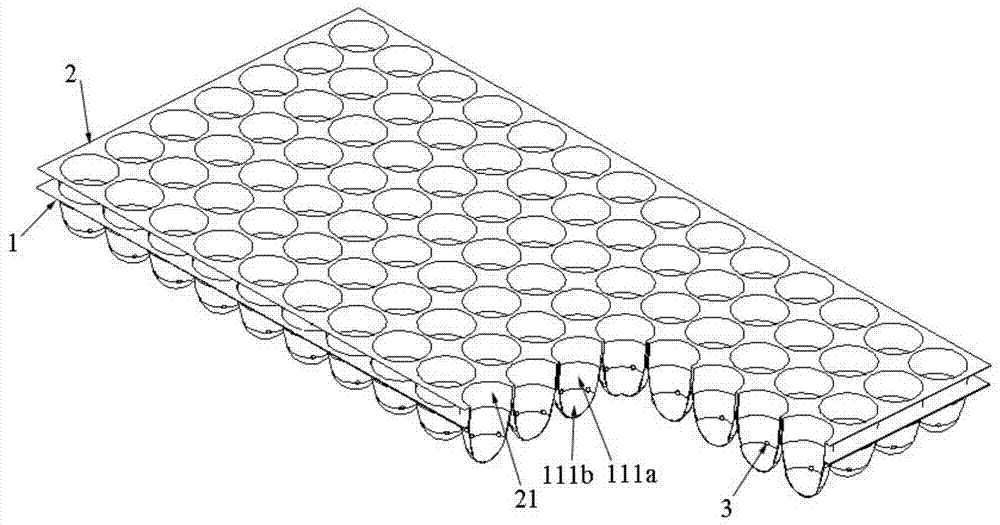

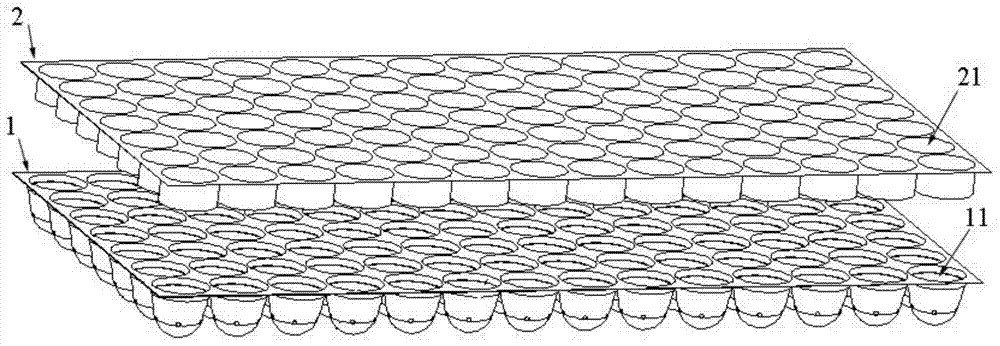

Method used

Image

Examples

no. 1 example

[0041] (1) Material preparation

[0042] Prepare the seedling substrate: choose a composite substrate whose components and ratio are vermiculite: peat: perlite = 5:4:1 (volume ratio).

[0043] Prepare seeds for seedlings: select cotton seeds that comply with GB-4407.1-1996, purchased from China Cotton Seed Industry Co., Ltd., the variety is Zhongmian Institute 50 (germination rate is 92%), and selected plump seeds.

[0044] Prepare other equipment, such as bed, agricultural film and so on.

[0045] (2) Sowing seedlings

[0046] Dry the seedlings properly before sowing.

[0047] The first is the seedling substrate packing. First mix the seedling substrate, add a small amount of water while mixing, so that the seedling substrate reaches a water content of 5% to 8%, stir evenly, transfer it to the bottom growth plate 1 with a shovel, and then quickly smooth and grow along the parallel plate surface On the surface of the plate 1, the growth hole 11 is filled with the seedling-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com