Equipment for slotting cardboard blanks

A technology of cardboard blanks and equipment, which is applied in the direction of bookcases for binding, paper/cardboard containers, papermaking, etc., and can solve problems such as roller damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

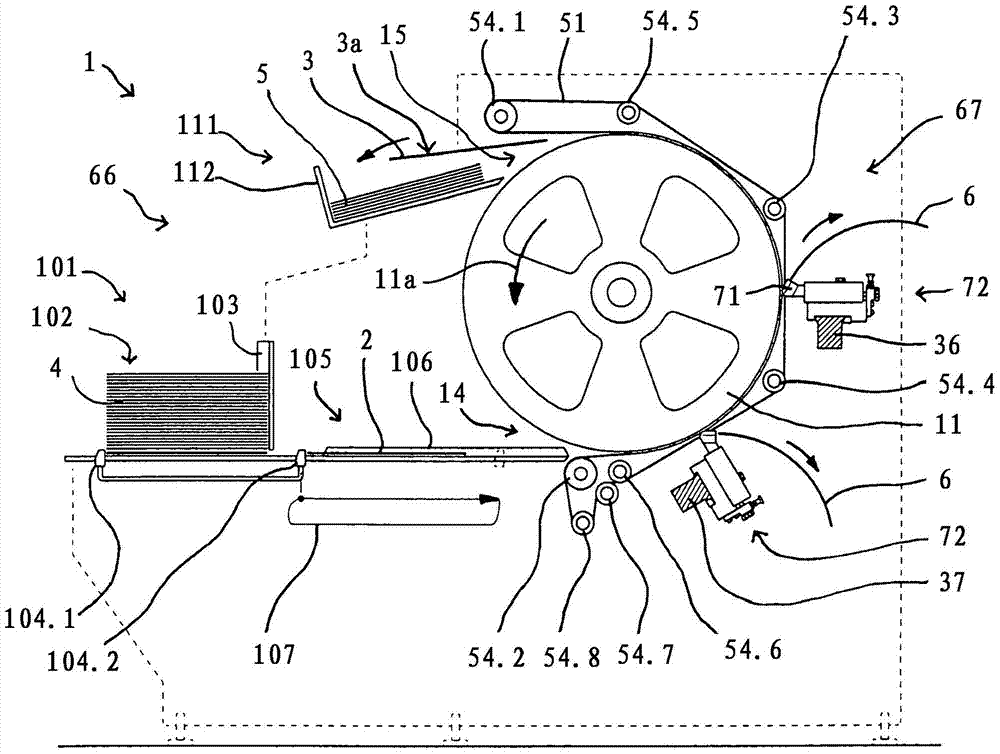

[0024] figure 1 The schematically shown grooving plant 1 basically comprises a driven, horizontally supported transport roller 11 and a plurality of rollers 54.1 to 54.8 which run continuously around and are spaced apart from each other, forming the inlet 14 and the outlet 15. The belts 51 which in some cases wrap around the transport roller 11 and the grooving knives 72 which are arranged between the belts 51 at a defined distance from the drum shell. The cardboard blank 2 conveyed by the conveying device 101 to the inlet 14 is pressed onto the roller shell by the belt 51 in an efficient conveying manner (foerderwirksam) and is transported along the conveying direction 11 a from the center of the conveying roller 11 during a rotation of the conveying roller 11 through approximately 180°. The inlet 14 at the lower apex leads to the outlet 15 at the upper apex and is guided there past a grooving knife 72 , where a correspondingly designed grooving knife 71 removes, for example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com