Automatic packaging device and method for small ceramic tiles

A technology for automatic packaging and small tiles, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of high labor intensity in packaging process, inability of packaging personnel to rest, affecting the health of operators, etc., to improve production efficiency and degree of mechanization. , Improve the suction accuracy, and the effect of high-reliability blanking and packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

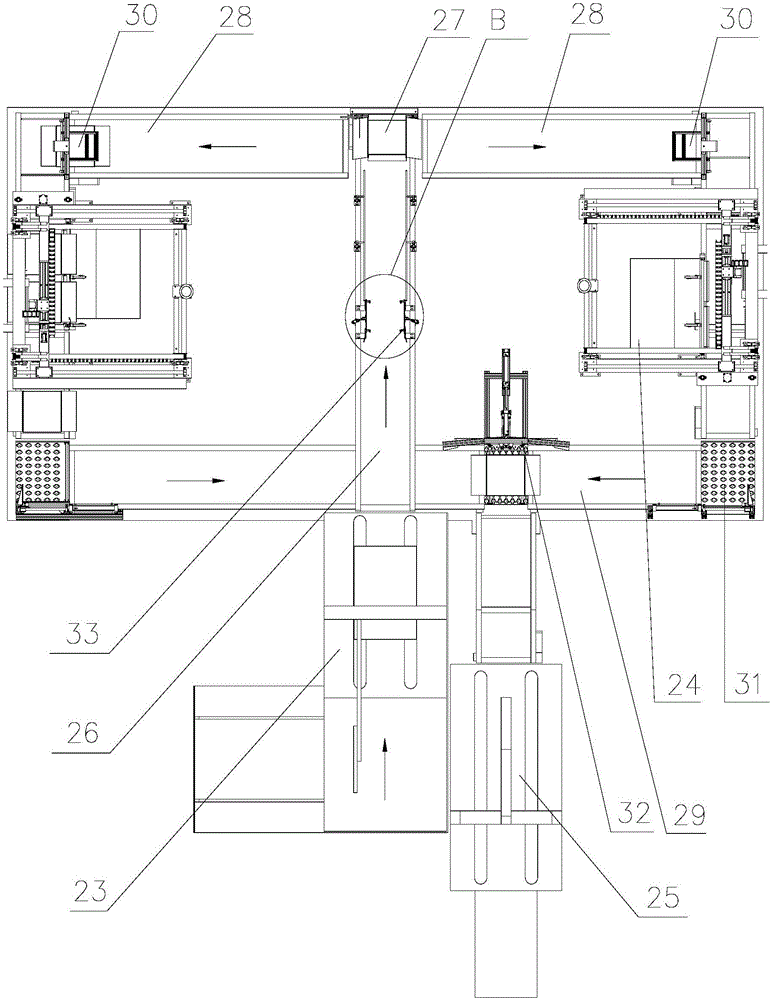

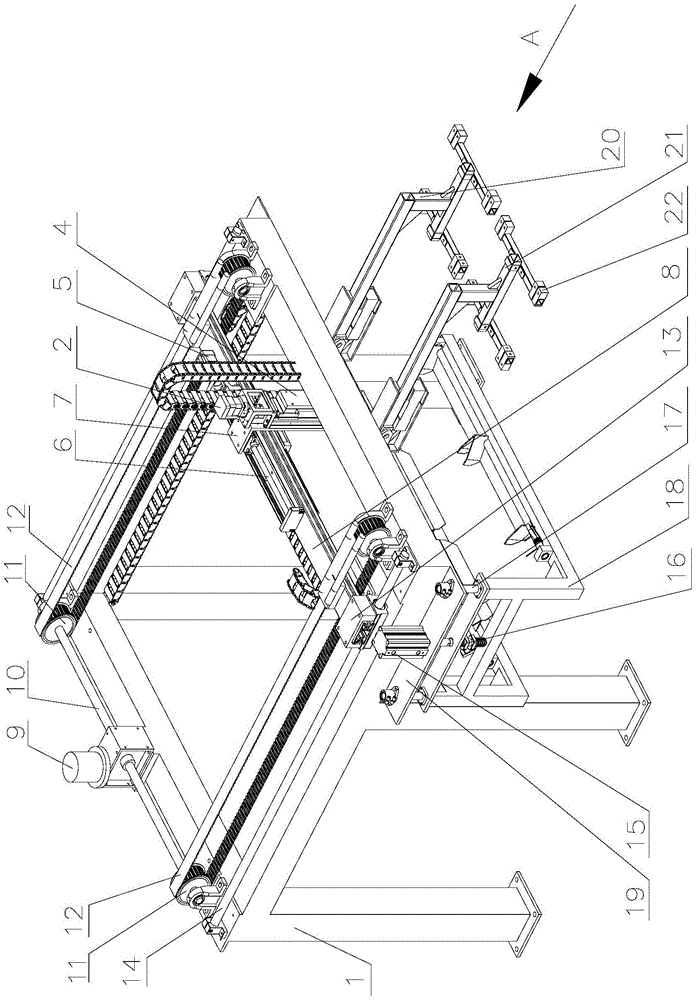

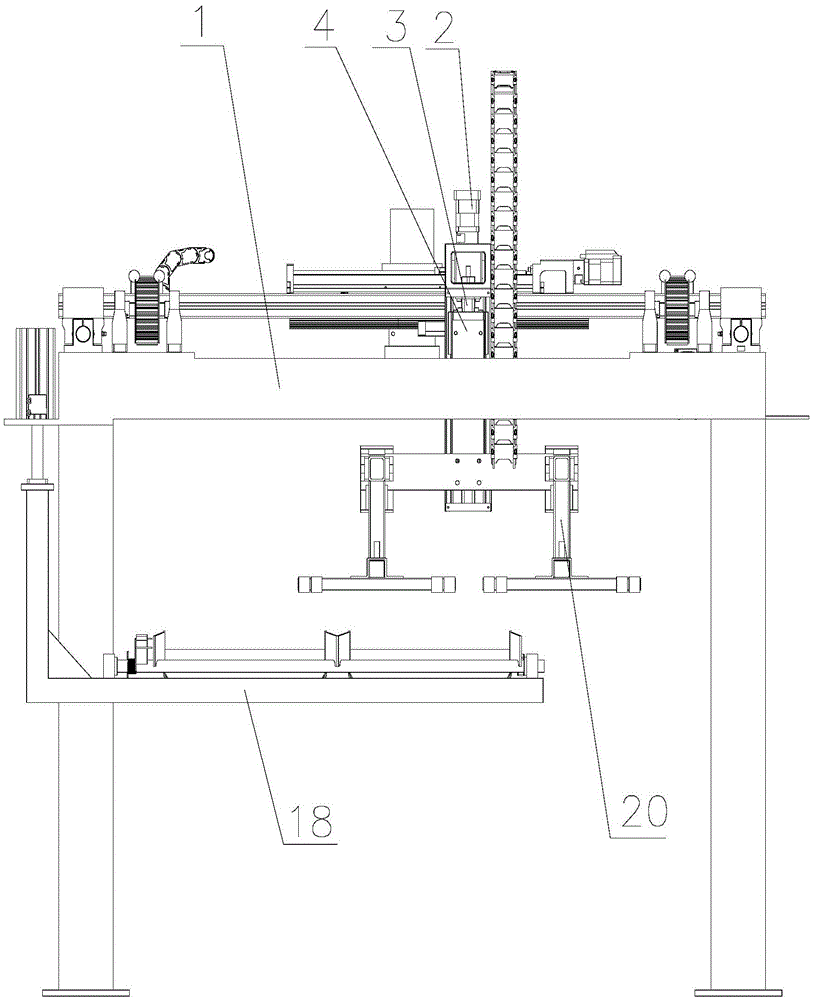

[0043] A kind of automatic packaging device for small tiles in this embodiment, such as figure 1 As shown, it includes an unpacking machine 23, a pick-and-loader 24 and a case sealing machine 25 connected successively by conveyor belts. The output end of the unpacking machine is provided with a longitudinal empty case conveyor belt 26, and the end of the longitudinal empty case conveyor belt is provided with a shunt mechanism 27. Horizontal empty case conveyor belts 28 are respectively arranged on both sides of the mechanism, and the output ends of each horizontal empty case conveyor belt are respectively connected to a loading machine, and the output ends of each loading machine are connected with the case sealing machine through the horizontal full box conveyor belt 29.

[0044] The loading and unloading machine is located on both sides of the longitudinal empty case conveyor belt, and the case sealing machine is located on the side of the case unpacking machine; the longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com