Method for producing high-purity aluminum nitride powder by using superfine metal aluminum powder

A technology of metal aluminum powder and aluminum nitride powder, which is applied in the field of non-metal powder material production, and can solve problems such as difficulty in application and purity less than 80%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

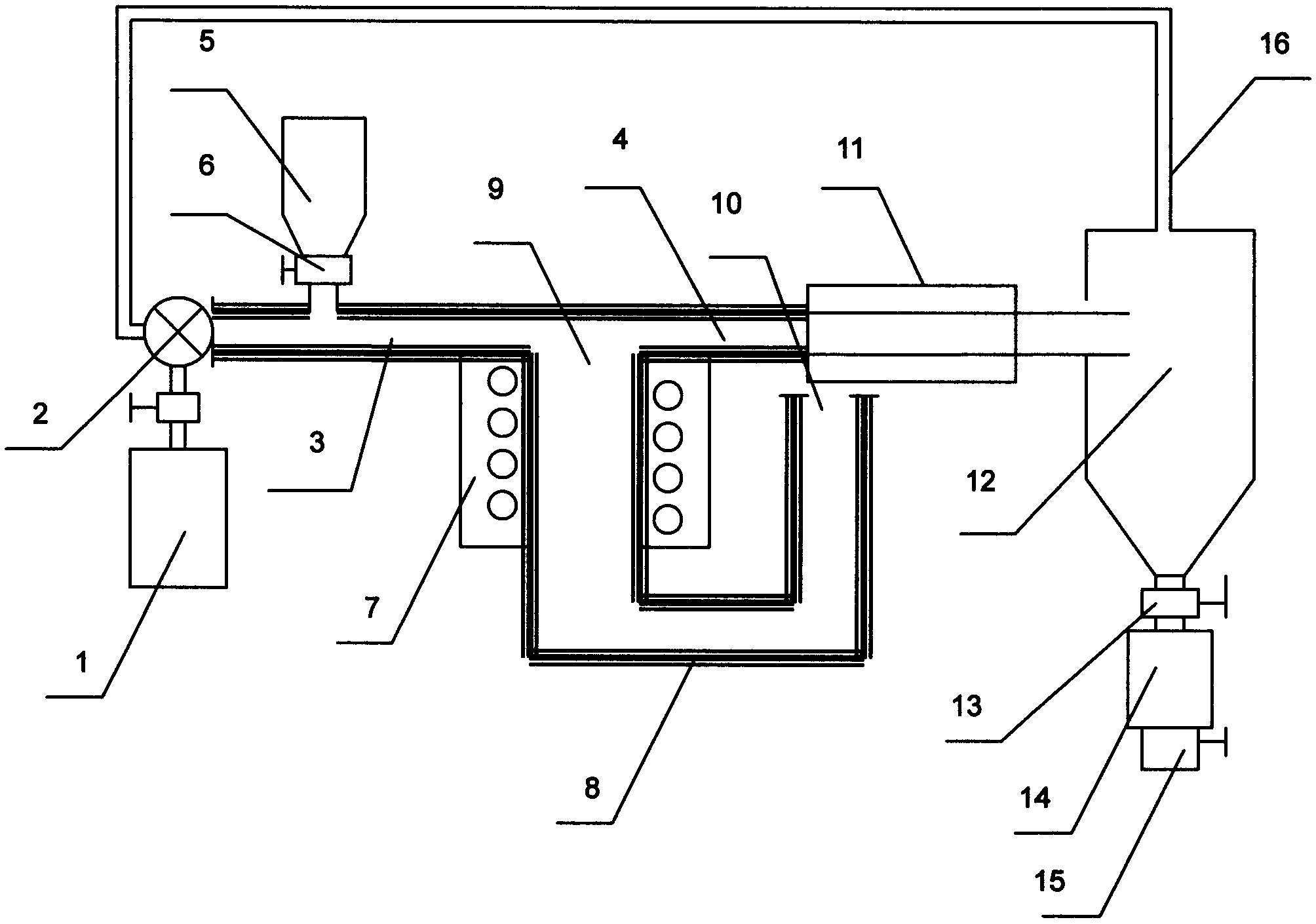

[0008] 1. Open the inlet valve (13) of the receiving tank, close the discharge valve (15) of the receiving tank, and open the valve of the high-purity nitrogen tank (1).

[0009] 2. Start the fan (2) and the heat exchanger (11) to make nitrogen with a purity greater than 99.9999% circulate in the device.

[0010] 3. Add molten aluminum with an aluminum content of 99.98% or more into the U-shaped furnace body (8) of the molten aluminum heater of the medium frequency furnace through the charging pipe (10) of the molten aluminum heater 9) The level of molten aluminum reaches the required height.

[0011] 4. Start the heating coil (7) of the molten aluminum heater of the intermediate frequency furnace to heat the molten aluminum to above 1400°C.

[0012] 5. Open the pulse valve (6) of the aluminum powder feeding tank, and add aluminum powder with an aluminum content of 99.99% or more and a particle size of less than 10μm into the medium frequency furnace aluminum liquid heater feed pipe (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com