Hydrochloric acid pickling corrosion and fog inhibitor and preparation method thereof

A fog inhibitor and corrosion inhibitor technology, which is applied in the field of hydrochloric acid pickling corrosion inhibitor and fog inhibitor, can solve the problem that the corrosion inhibitor, fog inhibitor and environmental protection performance of the corrosion inhibitor are difficult to achieve uniform excellence, polyaspartic acid Low anti-fog effect, unsatisfactory corrosion inhibition effect and other problems, to achieve significant practical value, excellent corrosion inhibition, and ensure the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

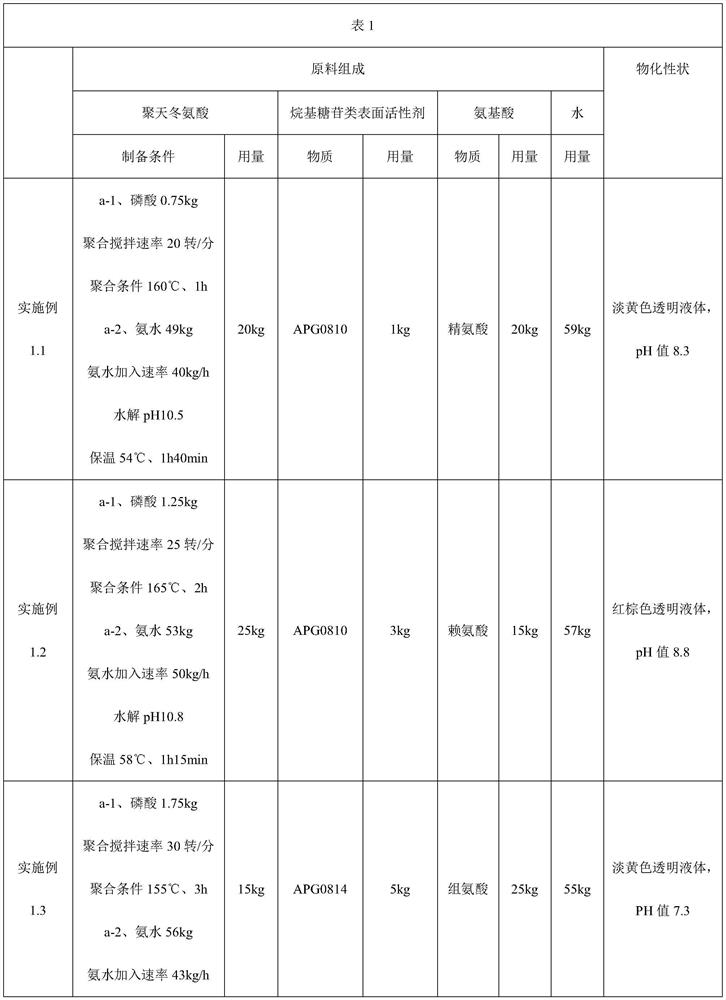

Embodiment 1

[0025] This embodiment relates to a kind of anti-corrosion and anti-fogging agent, its raw material composition includes:

[0026] Polyaspartic acid 5-25kg, light yellow to reddish brown viscous liquid, pH 7.0-9.0, average molecular weight 1000-3000;

[0027] Amino acid 5-25kg, choose from lysine, arginine, histidine;

[0028] Alkyl glycoside surfactant 1-5kg, selected from APG0810 and APG0814;

[0029] 45-79kg of water is used to prepare 100kg of corrosion and fog inhibitors.

[0030] Concrete preparation steps are as follows:

[0031] a-1. Add 75kg of L-aspartic acid into the polymerization reactor, then add 0.75~1.9kg of catalyst phosphoric acid, stir well, and heat up the polymerization at 20~30 rpm under continuous stirring to control the polymerization The temperature is 160±5℃, and the polymerization time is 1~3h;

[0032] a-2. After the polymerization reaction is finished and the reaction material is lowered to room temperature, the reaction material is transferred...

Embodiment 2

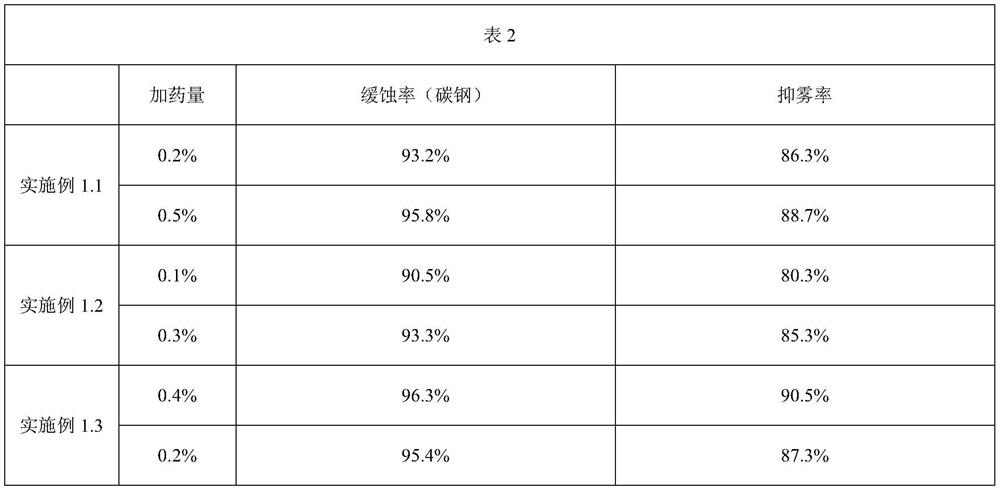

[0041] This example relates to the influence of polyaspartic acid obtained under different preparation conditions on the use effect of corrosion and fog inhibitors. The preparation of polyaspartic acid adopts the method of polymerization of L-aspartic acid and hydrolysis of lye, and the specific preparation conditions and application effects are shown in Table 3 below.

[0042]

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com