Hybrid energy dissipation vibration damping device

A vibration-damping device and energy-dissipating technology, which is applied to building components and earthquake-proofing, etc., can solve problems such as narrow optimum frequency band, and achieve the effects of increasing the vibration-damping frequency band, clear structure, and simple installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

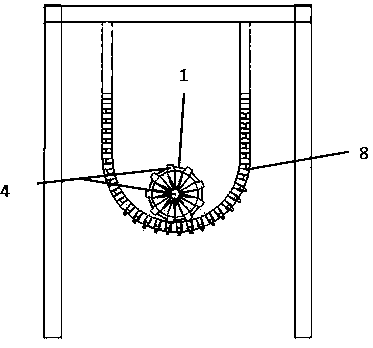

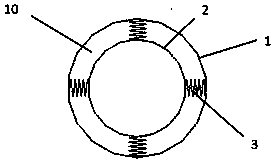

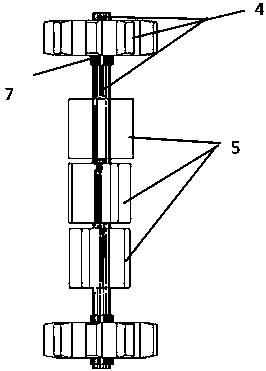

[0024] Example 1: A hybrid energy dissipation and vibration damping device, which is fixed to the main body of the structure in a suspended manner, including an outer tube body 1, an inner tube body 2, a spring 3, a central rotating shaft 4, a blade stirring device 5, and built-in damping The particles 6, the bearing 7, the suspension device 8, and the buffer material 10 between the inner and outer pipes. The inner tube 2 has built-in damping particles, and its internal structure can be modified, such as adding threads to increase the vertical movement of the particles when the cavity rotates, and improve the vibration reduction effect; image 3 , The 4-blade mixing device 5 is composed of three parts, namely the roller, the roller and the blade. The shape of the blades is variable, and can take the shape of four leaves, spiral leaves, etc.; spring 3 is a flexible spring, and when the cavity moves, the spring deforms to cause the internal cavity to vibrate, which intensifies the...

Embodiment 2

[0025] Embodiment 2: A hybrid energy dissipation and vibration damping device, which is fixed to the main structure by a guide rail type, includes an outer tube body 1, an inner tube body 2, a spring 3, a central rotating shaft 4, a blade stirring device 5, and built-in damping particles 6 , Connect the bearing 7, the guide rail and its installation device 9, and the buffer material 10 between the inner and outer pipes. Such as Figure 5 , Image 6 The guide rail is fixed to the main structure by bolts. The two ends of the central shaft 4 are placed on the guide rail. When the structure responds, the central shaft 4 drives the inner and outer pipes to roll along the guide rail, thereby driving the rotation of the blades in the pipe and the friction rolling of the damping particles. The rail-type implementation is the same as the first embodiment except that the rail and its installation device 9 are used instead of the suspension device 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com