Method for installing and leveling assembly type house PC prefabricated parts

A prefabricated component and assembled technology, which is applied in the direction of building construction, construction, and building material processing, can solve the problems of low installation efficiency and large elevation error, and achieve high installation efficiency, small elevation control error, and low overcoming efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

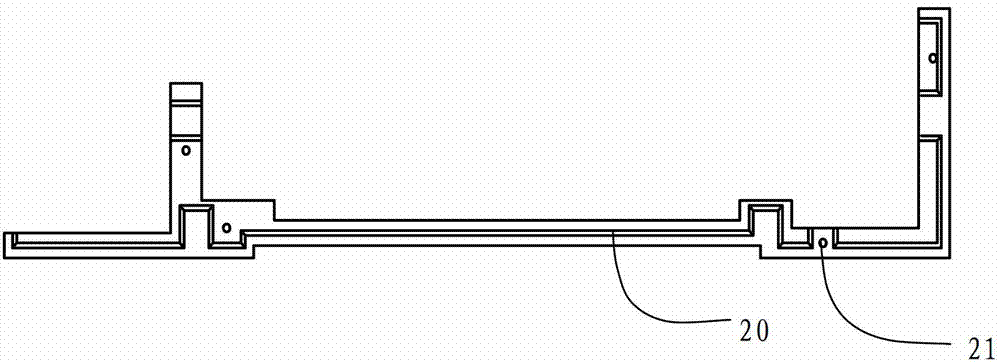

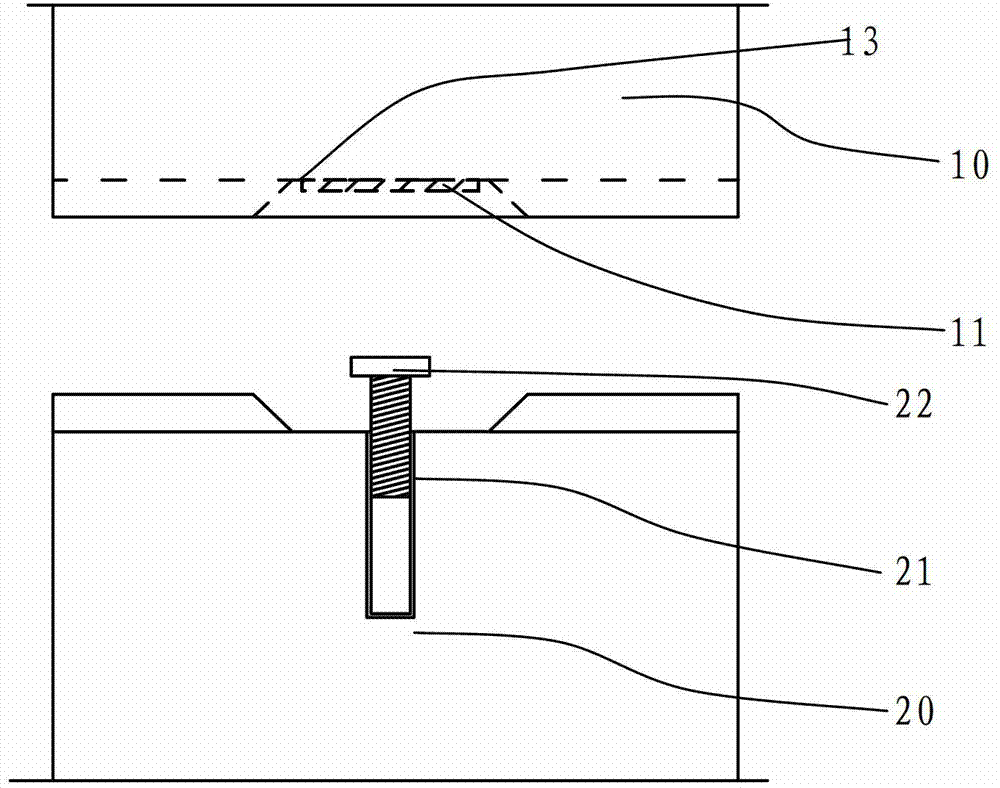

[0014] like figure 1 or image 3 As shown, four bolt sleeves 21 are pre-embedded on the top surface of the lower prefabricated member 20 . The adjusting screw 22 can be screwed into the screw sleeve 21 .

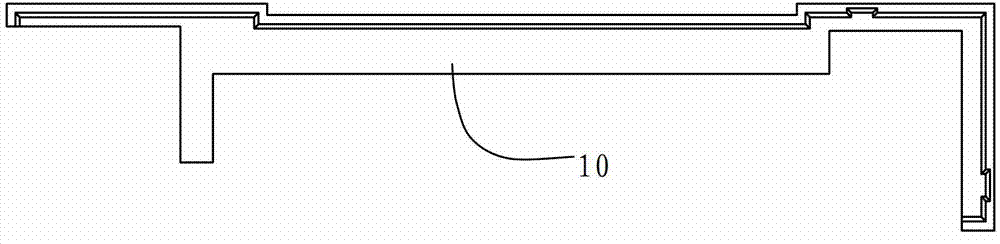

[0015] like figure 2 or image 3 As shown, when the upper layer prefabricated member 10 is poured, the position where the upper layer prefabricated member 10 contacts the bolts 22 of the lower layer prefabricated member 20 is set to form a reference plane 13, and a steel plate is placed on the reference plane 13.

[0016] further cooperation image 3 , 4 , 5, the prefabricated housing PC prefabricated component installation and leveling method of the present invention comprises the following steps:

[0017] 1) Install the lower prefabricated member 20, and the top surface of the lower prefabricated member 20 is pre-buried with two or mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com