Four-way pipe connector

A technology of pipe joints and spools, applied in the direction of pipes/pipe joints/pipes, pipes, branch pipelines, etc. Easy to slip, reasonable structure and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

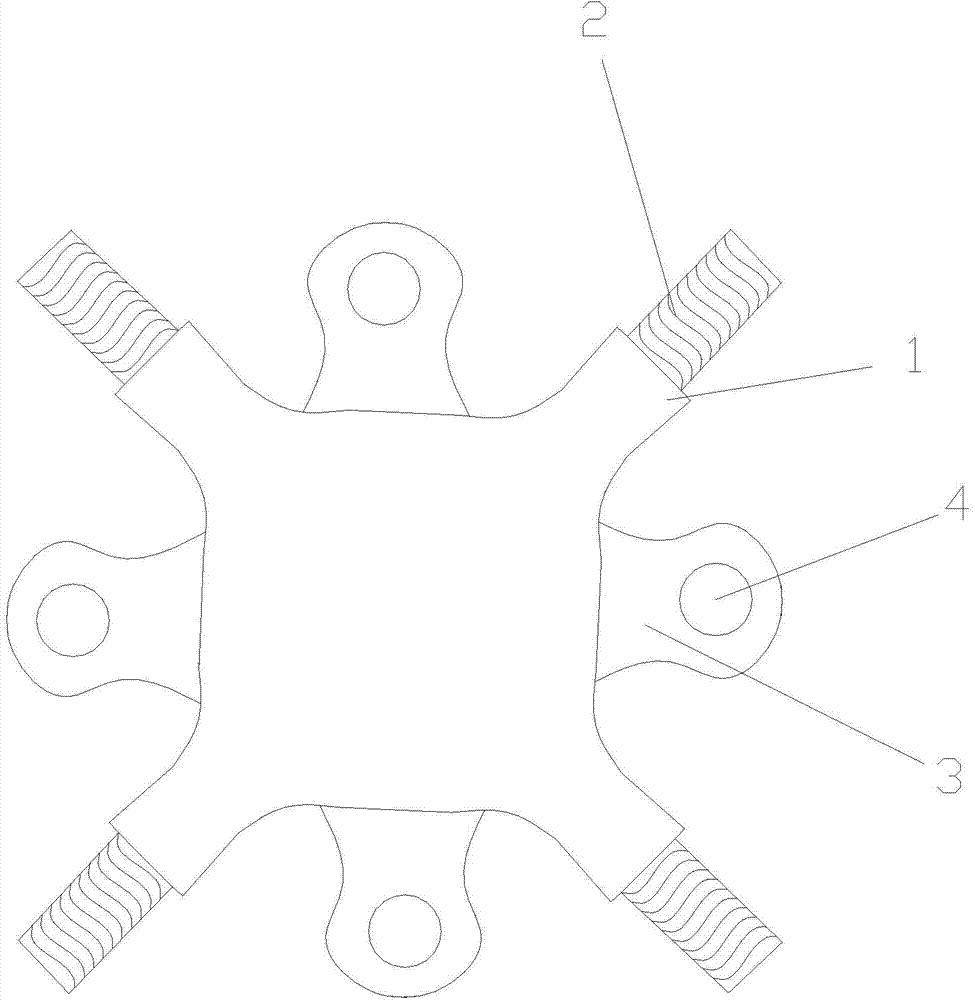

[0011] Such as figure 1 As shown, a four-way pipe joint includes a body, the body includes four pipe joints 1 uniformly arranged, and the end sides of the pipe joints 1 are provided with connecting threads 2, and the body also includes fixed pipe joints 1 arranged at uniform intervals. The ear 3 is provided with a fixed connection hole 4 on the fixed ear 3 . The fixed ear 3 is in the shape of a sheet, and the outer edge is provided with a circular arc with uniform transition.

[0012] The basic principles and main features of the present invention and the advantages of the present invention have been shown and described above. Those skilled in the industry should understand that the present invention is not limited by the above-mentioned embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com