Large size speckle full-field strain measurement method

A technology of strain measurement and speckle, which is applied in the field of strain measurement, can solve the problems of difficult camera calibration and achieve the effect of wide application range, high measurement efficiency and simple system equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

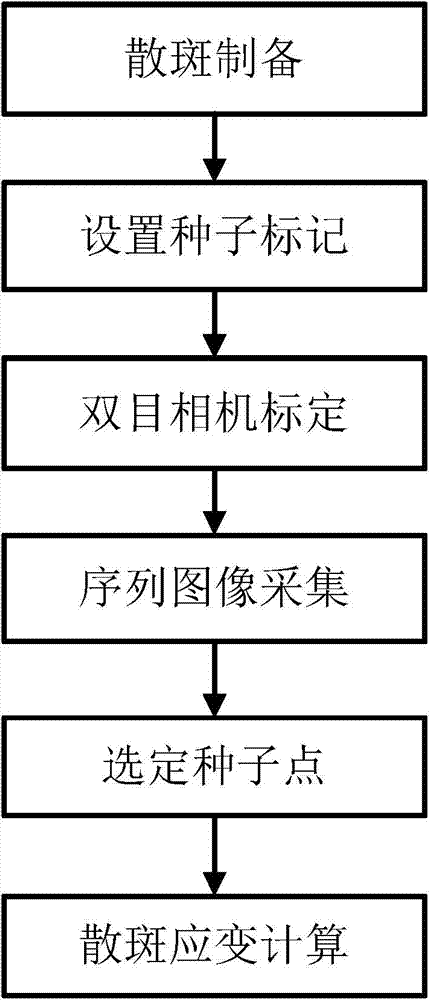

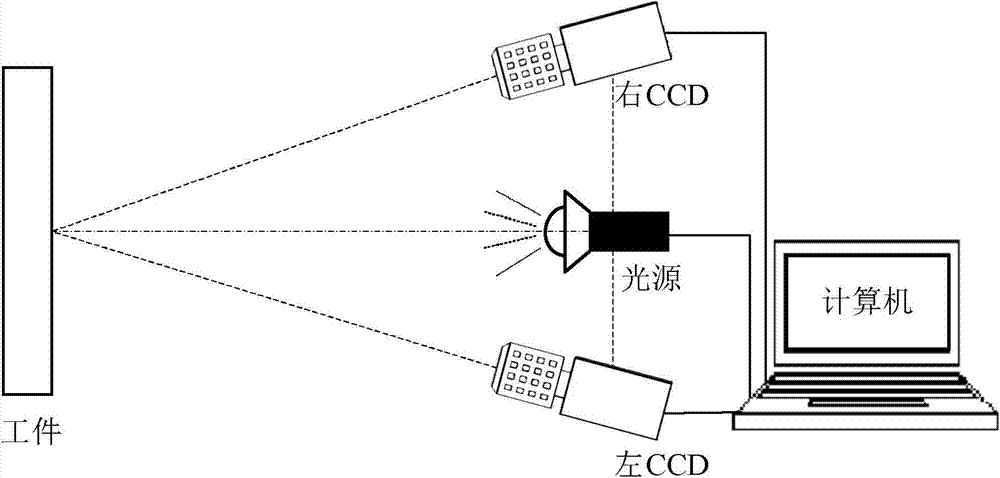

[0029] The present invention proposes a large-scale speckle full-field strain measurement method, the specific operation steps are as follows figure 1 shown. The hardware device used consists of figure 2 As shown, it is mainly composed of 2 CCD cameras, 1 high-frequency LED light source and 1 computer. In a particular embodiment, the large format workpiece is a thin steel plate with dimensions 800mm x 600mm x 2mm.

[0030] The first step, speckle preparation: use black and white two-color matte paint and a spray template to perform speckle printing on the measurement area on the surface of the large-scale workpiece to be measured, such as image 3 shown. Speckle preparation can also be done manually (such as Figure 4 shown). Preferably, speckle preparation requires: a) speckle features should be randomly distributed, and large black or white areas can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com