Micro-defect detection method on silicon steel plate surface based on salient active contour model

An active contour model, defect detection technology, used in optical testing flaws/defects, image data processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

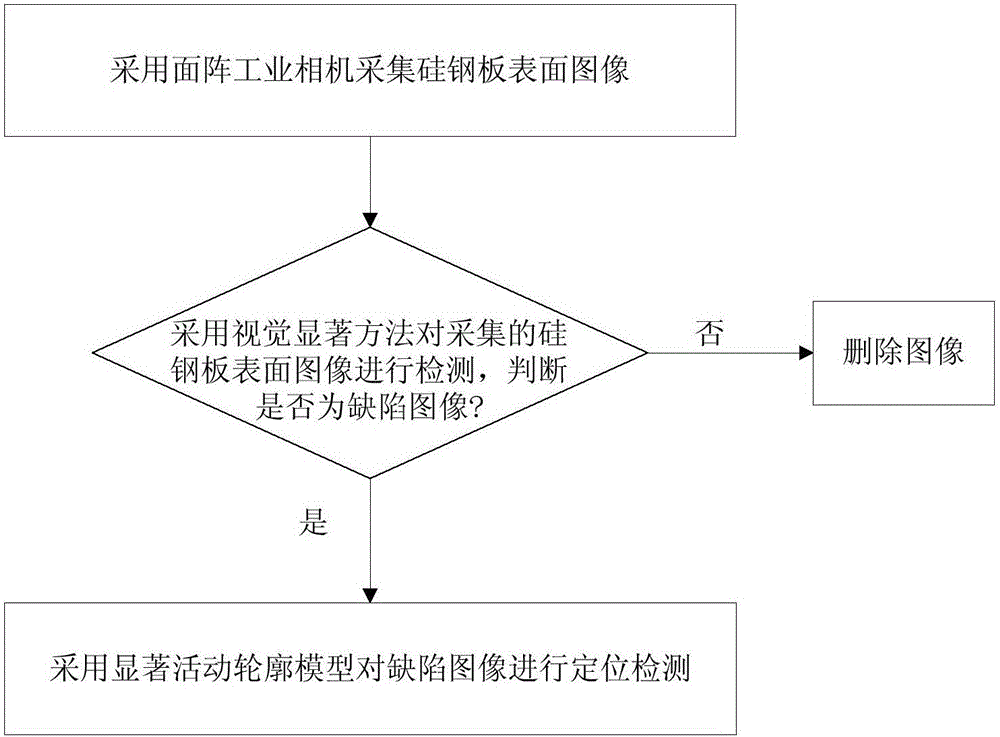

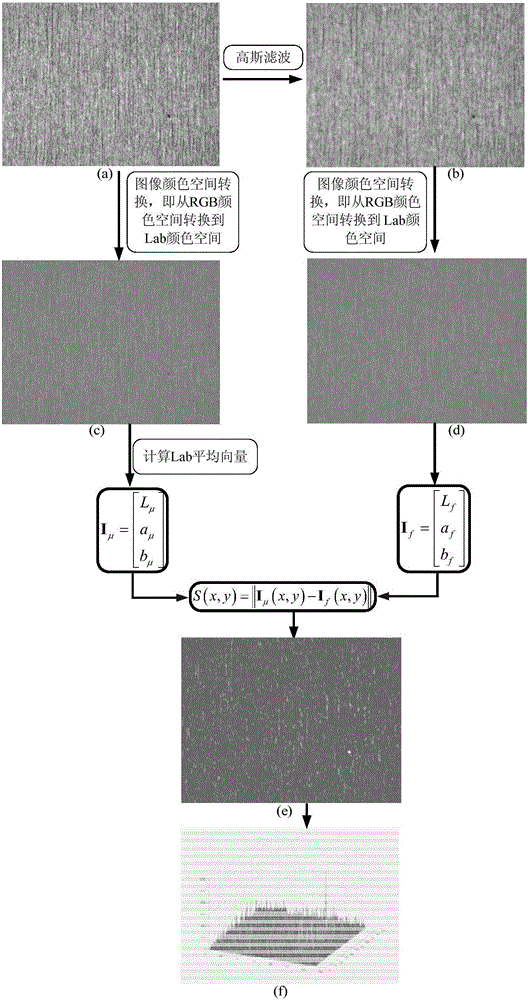

Method used

Image

Examples

specific Embodiment approach

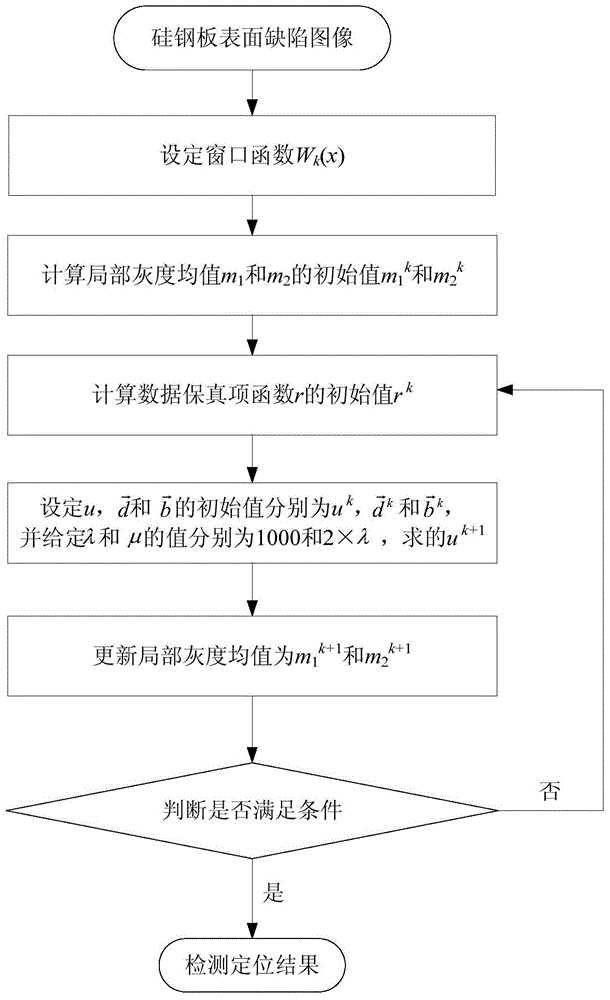

[0096] Such as image 3 As shown, the flow chart of positioning and detection of the method of combining the salient active contour model of an embodiment of the present invention, the specific implementation is as follows:

[0097] Step 3-1. Set the window function W k (x), the window used here is the widely used Gaussian window, the value of σ is 3, and the window size is 4σ+1.

[0098] Step 3-2, the local window function W k (x) into the following formula to get the local gray mean value: the gray mean value of pixels within the curve m 1 and the average gray value of pixels outside the curve m 2 The initial value of m 1 k and m 2 k , where φ is the level set function.

[0099] m 1 =mean(S∈({x∈Ω|φ(x)k (x)))

[0100] m 2 =mean(S∈({x∈Ω|φ(x)>0}∩W k (x)))

[0101] Step 3-3, put m 1 k and m 2 k Bring it into the following formula to get the initial value r of the data fidelity function r k , where k is the number of iterations, and S(x) represents the pixel dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com