Rapidly dissolving oral tablet

A technology for intra-oral, fast-disintegrating tablets, which is applied in the fields of non-active ingredient medical preparations, pill delivery, respiratory diseases, etc., to achieve sufficient hardness and excellent intra-oral disintegration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] Embodiments of the present invention will be described in detail below based on examples. In addition, the hardness of a tablet, oral disintegration time, and bitterness masking were measured as follows.

[0102] Hardness test method

[0103] The hardness of the orally rapidly disintegrating tablet of the present invention was measured using a tablet hardness meter (model: 8M) manufactured by Schleuniger. The measurement was carried out 3 times, and the average value was taken as the hardness of the tablet.

[0104] Determination of oral disintegration time

[0105] The oral disintegration time of the oral rapidly disintegrating tablet of the present invention is as follows: healthy adult men (3 people) each took one tablet in the mouth without using water for taking it, and placed it in the mouth in a state of standing (without performing Under behaviors such as chewing and vigorously moving the tongue), the time until the tablet was completely disintegrated by ...

Embodiment 1

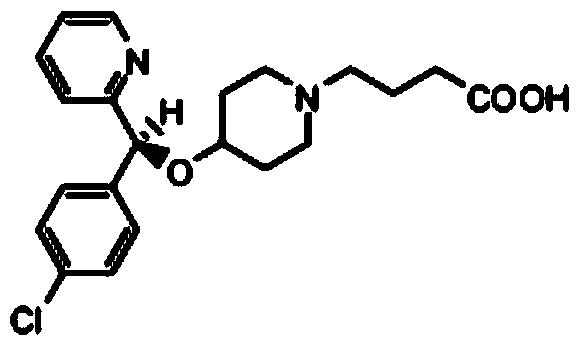

[0110] (1) 13 g of bepotastine besylate, 65 g of β-cyclodextrin, 288.6 g of D-mannitol, and 11.7 g of hydroxypropylmethylcellulose acetate succinate (grade; HF) were added to polyethylene After mixing in bag making, sieve through Japanese Pharmacopoeia No. 22 sieve (pore size: 710 μm). The obtained sieved product was charged into a fluidized bed granulator (manufactured by Powrex, MP-01 / 03), and granulated while spraying 200 g of purified water at a supply air temperature of 50° C. for about 50 minutes. Drying was carried out until the temperature of the granulated matter reached 35° C. or higher, and all the dried matter passed through a Japanese Pharmacopoeia No. 22 sieve (pore size: 710 μm), thereby obtaining granulated granules.

[0111](2) 5.82 g of the granulated granules of (1) above, 0.12 g of crospovidone, 0.06 g of aspartame, and 0.06 g of sodium stearate fumarate were mixed to obtain granules for tableting. Using the obtained granules for tableting, compression mol...

Embodiment 2

[0113] (1) Add 0.3 g of bepotastine besylate, 3 g of β-cyclodextrin, 5.16 g of D-mannitol, and 0.27 g of hydroxypropylmethylcellulose acetate succinate (grade; HF) in poly After mixing in vinyl bags, sieve through Japanese Pharmacopoeia No. 22 sieve (pore size: 710 μm). After adding 0.5 g of purified water to the obtained sieved product and performing granulation, it was dried in a ventilated box-type dryer at 50°C for 1 hour, and all the dried product passed through a No. Granulated particles are thus obtained.

[0114] (2) 5.82 g of the granulated granules of (1) above, 0.12 g of crospovidone, 0.06 g of aspartame, and 0.06 g of sodium stearate fumarate were mixed to obtain granules for tableting. Using the obtained granules for tableting, compression molding is performed with a tableting analyzer (manufactured by Kikusui Seisakusho, punch: 10mm in diameter, tableting pressure: 300kg / punch) so that the content of each tablet is 303mg, thereby obtaining rapid disintegration i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com