Film-forming coating liquid manufacturing method of film-forming coating liquid and film-covered base material

A manufacturing method and technology of coating liquid, applied in the direction of coating, etc., can solve the problems of difficulty in suppressing cracks, insufficient chemical resistance, low cross-linking degree of the coating, and achieve sufficient hardness, scratch resistance, resistance to Excellent chemical properties and hard to crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0155] Each process for manufacturing the coating liquid for film formation and the base material with a film is as follows. Table 1 shows the types and compounding quantities of each component to be compounded.

[0156] (preparatory process 1)

[0157] 4673.08 g of hexanediol (manufactured by Wako Pure Chemical Industries, Ltd.), 214.07 g of pure water, and 3.57 g of nitric acid with a concentration of 60% by mass were mixed and stirred for 5 minutes. Next, 1,2-bis(triethoxysilyl)ethane (manufactured by YAMANAKA HUTECH CORPORATION: SiO 2 Concentration: 33.8% by mass) 1055.55 g was stirred for 30 minutes to prepare a preparatory liquid 1-1 having a solid content concentration of 6.0% by mass.

[0158] (preparatory process 2)

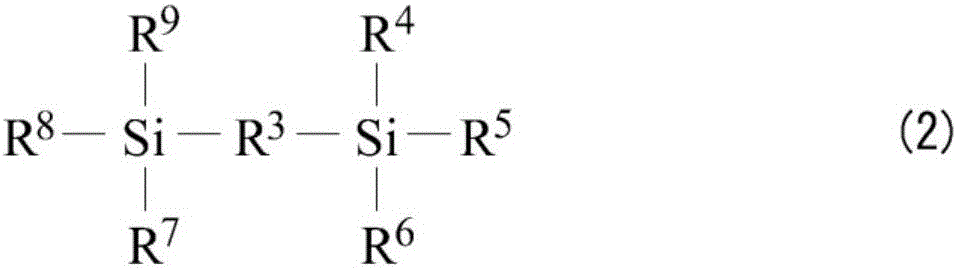

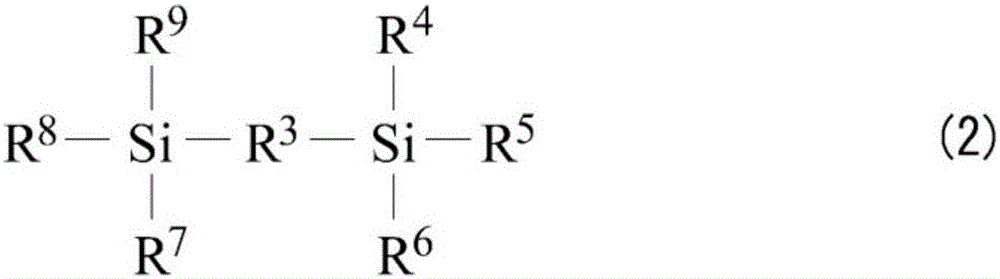

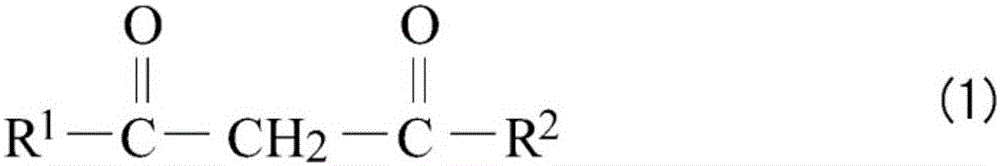

[0159] 2966.06 g of hexanediol (manufactured by Wako Pure Chemical Industries, Ltd.), 148.66 g of acetylacetone (manufactured by Wako Pure Chemical Industries, Ltd.) as a component A carbonyl-containing organic compound, and Orgatix TA-10 (Matsumoto F...

Embodiment 2

[0170] Except for the following preparatory process, it carried out similarly to Example 1, the coating liquid (2) for film formation was prepared, and the base material (2-1)-(2-3) with a film was produced further. Then, it carried out similarly to Example 1, and evaluated.

[0171] (preparatory process 1)

[0172] 5841.36 g of hexanediol (manufactured by Wako Pure Chemical Industries, Ltd.), 267.58 g of pure water, and 4.46 g of nitric acid with a concentration of 60% by mass were mixed and stirred for 5 minutes. Next, 1,2-bis(triethoxysilyl)ethane (manufactured by YAMANAKA HUTECH CORPORATION: SiO 2 Concentration: 33.8% by mass) 1319.44 g was stirred for 30 minutes to prepare a preparatory liquid 1-2 having a solid content concentration of 6.0% by mass.

[0173] (preparatory process 2)

[0174] 1853.78 g of hexanediol (manufactured by Wako Pure Chemical Industries, Ltd.), 92.91 g of acetylacetone (manufactured by Wako Pure Chemical Industries, Ltd.) as a component A carbo...

Embodiment 3

[0176] Except for the following preparatory steps, it was carried out in the same manner as in Example 1 to prepare a coating solution (3) for film formation, and further to produce substrates (3-1) to (3-3) with a film. Then, it carried out similarly to Example 1, and evaluated.

[0177] (preparatory process 1)

[0178] 6620.20 g of hexanediol (manufactured by Wako Pure Chemical Industries, Ltd.), 303.26 g of pure water, and 5.05 g of nitric acid with a concentration of 60% by mass were mixed and stirred for 5 minutes. Next, 1,2-bis(triethoxysilyl)ethane (manufactured by YAMANAKA HUTECH CORPORATION: SiO 2 Concentration: 33.8% by mass) 1495.36 g was stirred for 30 minutes to prepare a preparatory solution 1-3 having a solid content concentration of 6.0% by mass.

[0179] (preparatory process 2)

[0180] 1112.27 g of hexanediol (manufactured by Wako Pure Chemical Industries, Ltd.), 55.75 g of acetylacetone (manufactured by Wako Pure Chemical Industries, Ltd.) as a component ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com