Antiglare film

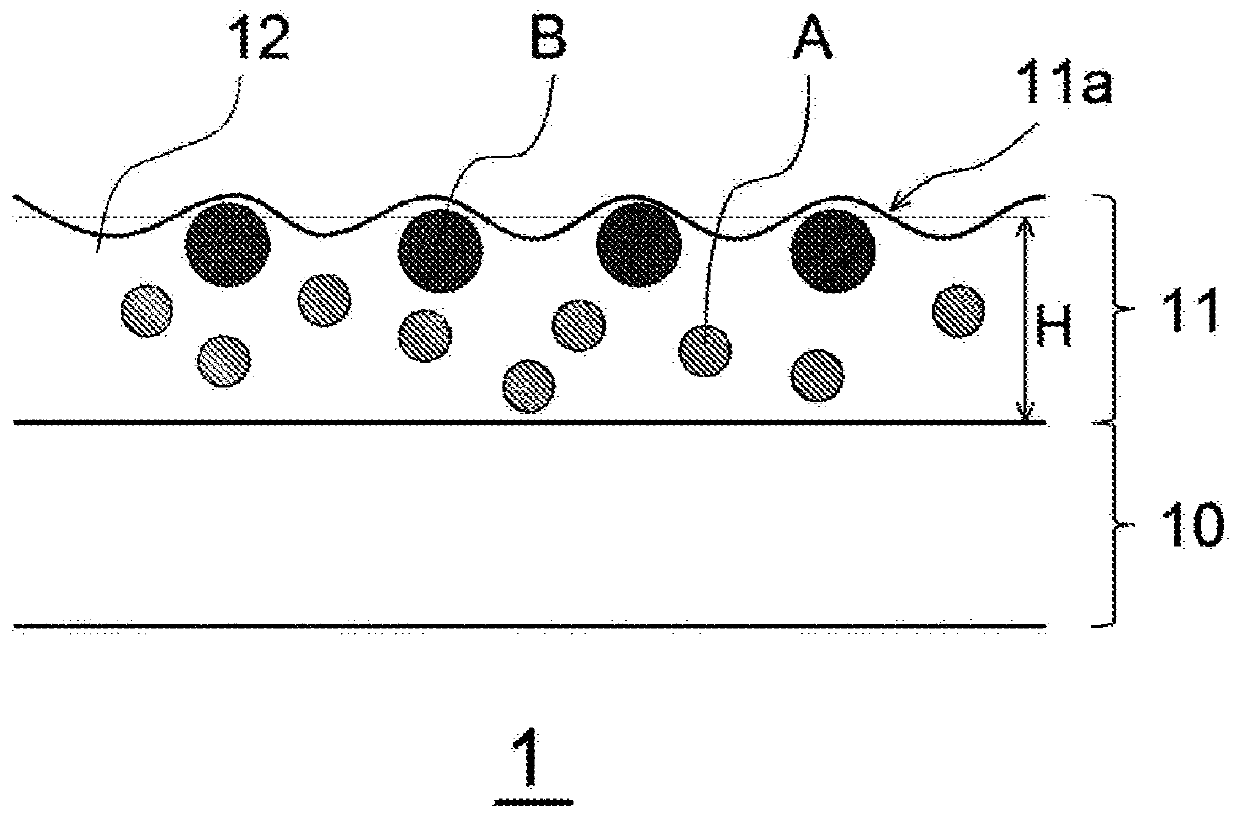

A technology of anti-glare film and anti-glare layer, which is applied in the direction of optics, instruments, optical components, etc., can solve the problems of ambiguity in the specific means of surface shape, and achieve the effects of not being dazzling, sufficient hardness, and improved anti-glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

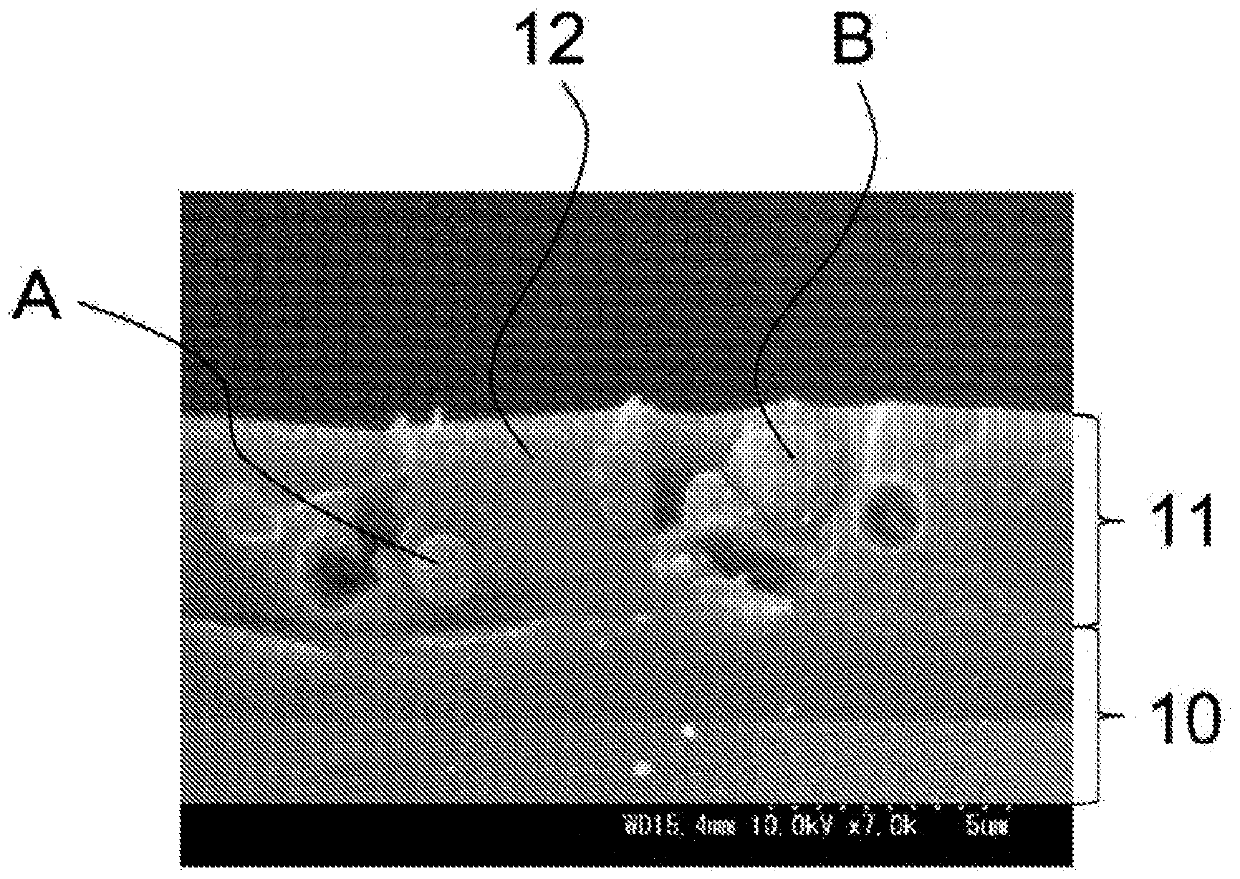

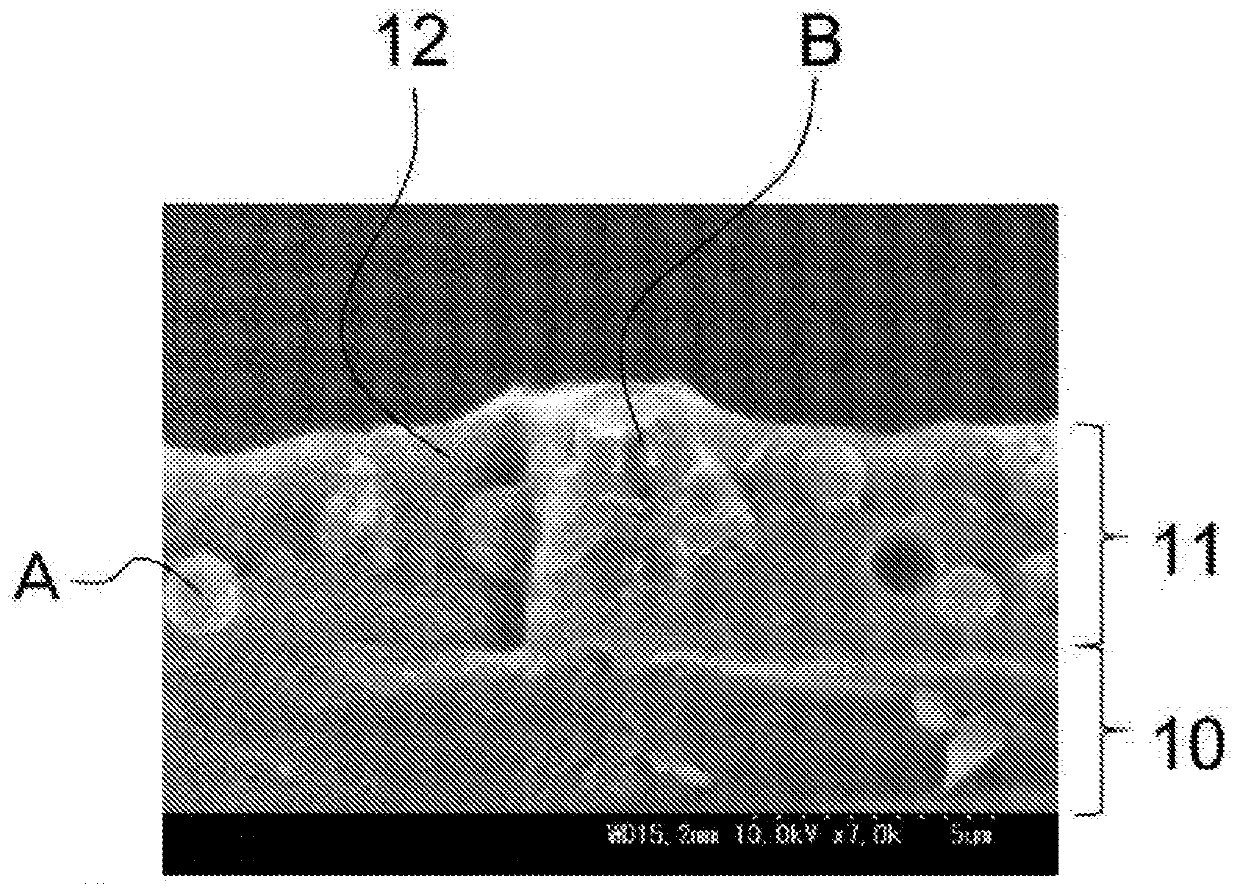

[0125] As the base film, a transparent TAC (triacetyl cellulose) film with a thickness of 80 μm was used, and the anti-glare layer forming liquid 1 of the following formulation was applied to the other surface, dried and irradiated with ultraviolet rays to form a film with an average thickness of 4.5 μm. Anti-glare layer, and make anti-glare film.

[0126] It should be noted that the density and the refractive index of the material composed of the liquid mean the density and the refractive index of the solid component, respectively, except for the solvent.

[0127]

[0128]

[0129]

[0130] First, the haze value of the produced antiglare film and the haze value of the base film (transparent TAC film) which did not form an antiglare layer were measured based on JISK7136.

[0131] The value obtained by subtracting the haze value of the base film (transparent TAC film) from the haze value of the prepared anti-glare film was taken as the total haze value.

[0132] Next, a...

experiment example 2

[0143] An antiglare film was prepared and evaluated in the same manner as in Experimental Example 1 except that the antiglare layer forming liquid 1 in Experimental Example 1 was changed to the antiglare layer forming liquid 2 of the following formulation.

[0144]

[0145]

[0146]

[0147]It should be noted that the UV curable organic-inorganic hybrid acrylic resin used in the antiglare layer forming liquid 2 is a type of organic-inorganic hybrid resin that contains reactive nano-silica and forms an organic-inorganic composite by UV irradiation.

experiment example 3

[0149] An antiglare film was prepared and evaluated in the same manner as in Experimental Example 1 except that the antiglare layer forming liquid 1 in Experimental Example 1 was changed to the antiglare layer forming liquid 3 of the following formulation.

[0150]

[0151]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com