Checking apparatus for a camera, and a method for checking a camera

An inspection device and inspection method technology, which is applied in the field of inspection cameras, inspection device applications, and inspection systems, can solve problems such as interference with oversensitivity, reduction, artifacts, and disturbing quality, and achieve compact inspection devices, compact devices, and reliable performance. The effect of sex and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

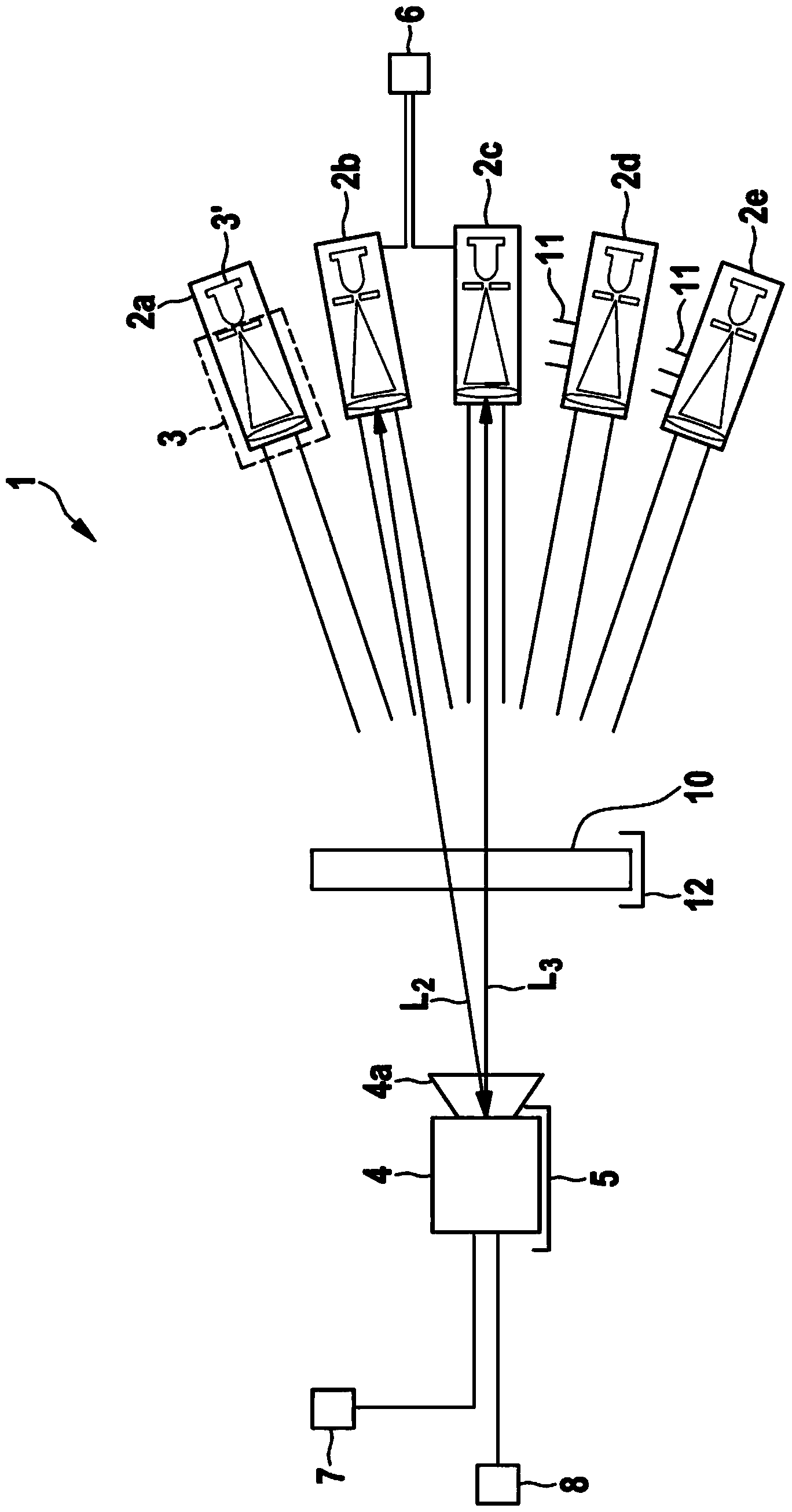

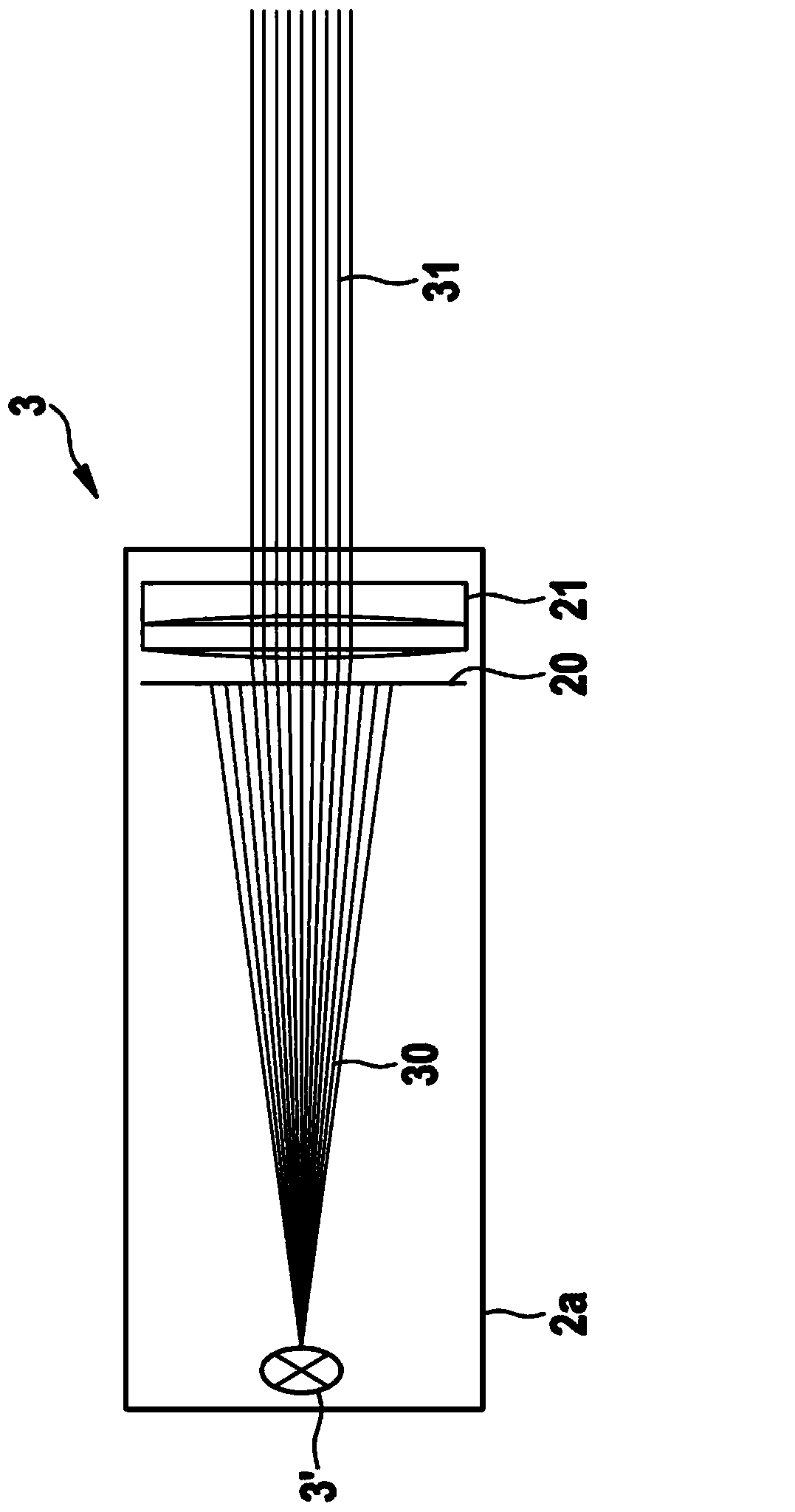

[0021] figure 1 A cross-section of an inspection device according to a first embodiment of the present invention is schematically shown.

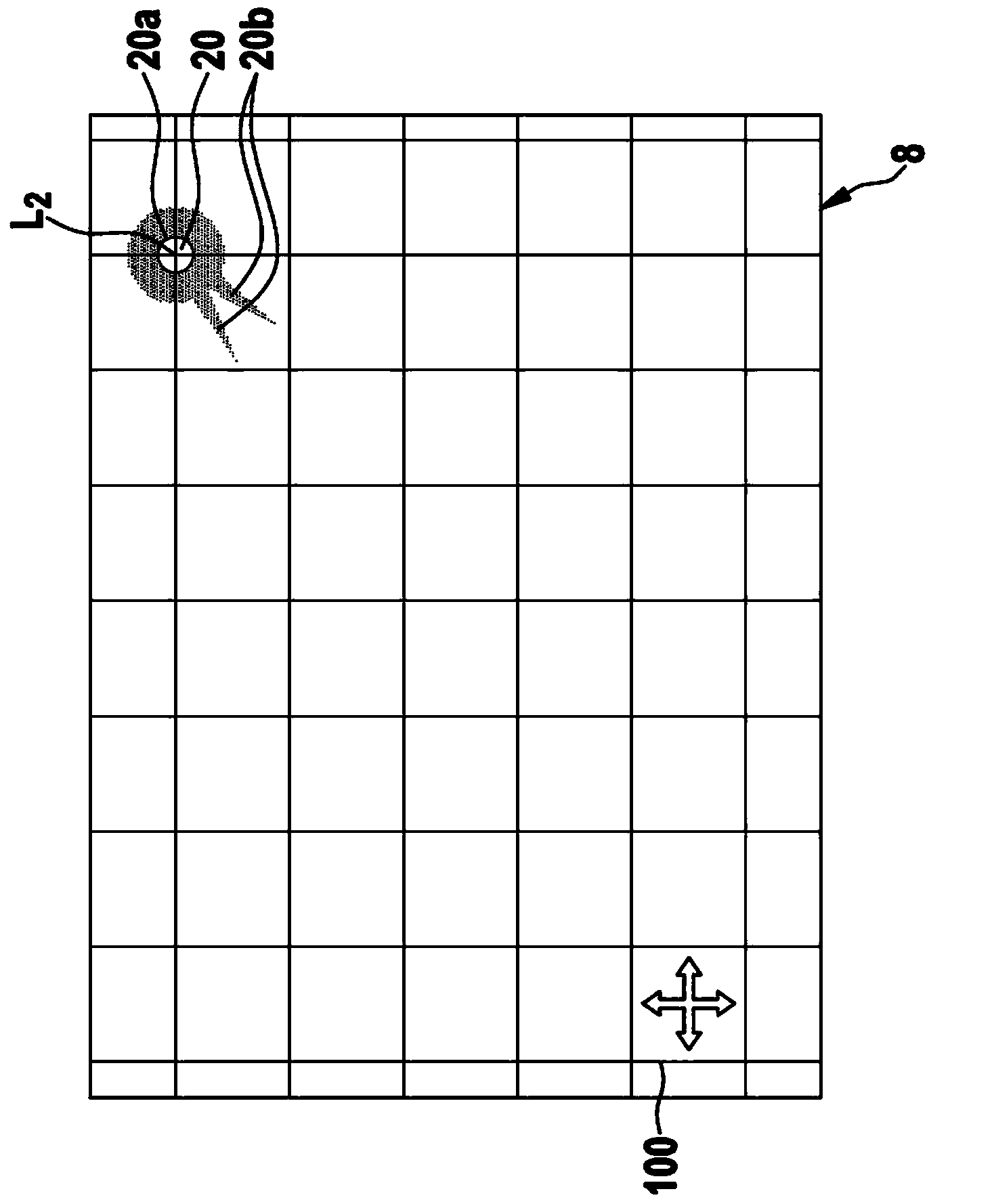

[0022] exist figure 1 In , reference numeral 1 designates an inspection device for a camera 4 comprising optics 4a. The camera 4 is connected to an evaluation device 7 , 8 , wherein the evaluation device is designated with reference numeral 7 , which automatically evaluates the images recorded by the camera 4 . Reference sign 8 denotes a monitor on which the images of camera 4 are displayed and, if appropriate, the evaluation results of evaluation device 7 are displayed for the user. The camera 4 is arranged in a holding device 5 which is in particular arranged stationary relative to the light sources 2a-2e. The light sources 2a-2e are arranged at least partially circularly around the imaging optics 4a of the camera 4, so that they can emit light with their respective light L 2 , L 3 Load camera 4. Here, the light sources 2 a - 2 e ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com