Elliptical printing machine and printing method of elliptical printing machine in movement of printing bedplates

A printing machine, ellipse technology, applied in the field of ellipse printing machine and its printing in the printing platen movement, can solve the problems of fuzzy printing error, electronic component failure, positioning error amplification, etc., to eliminate positioning error and improve printing accuracy , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

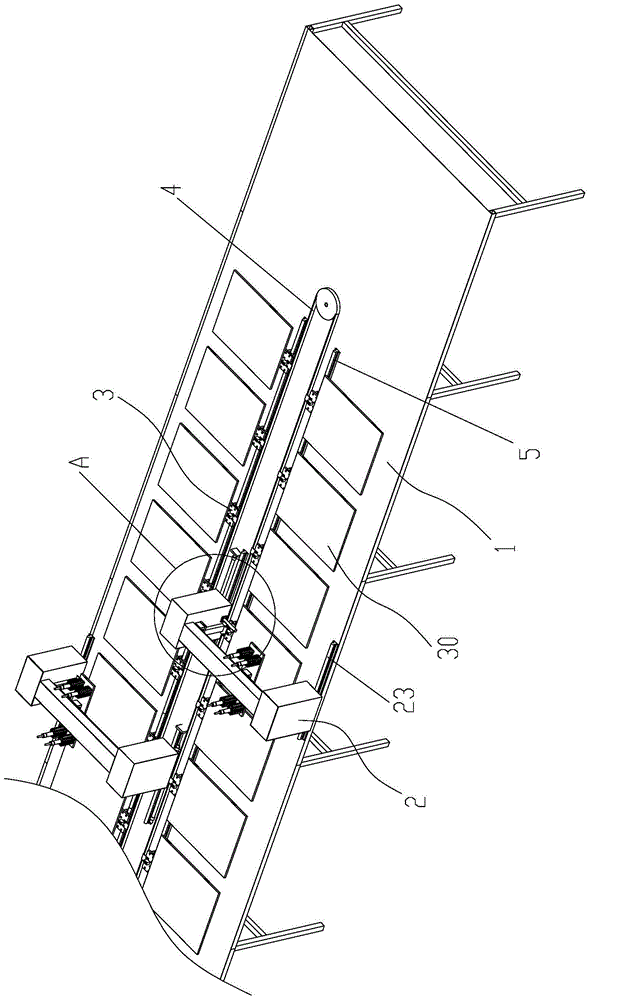

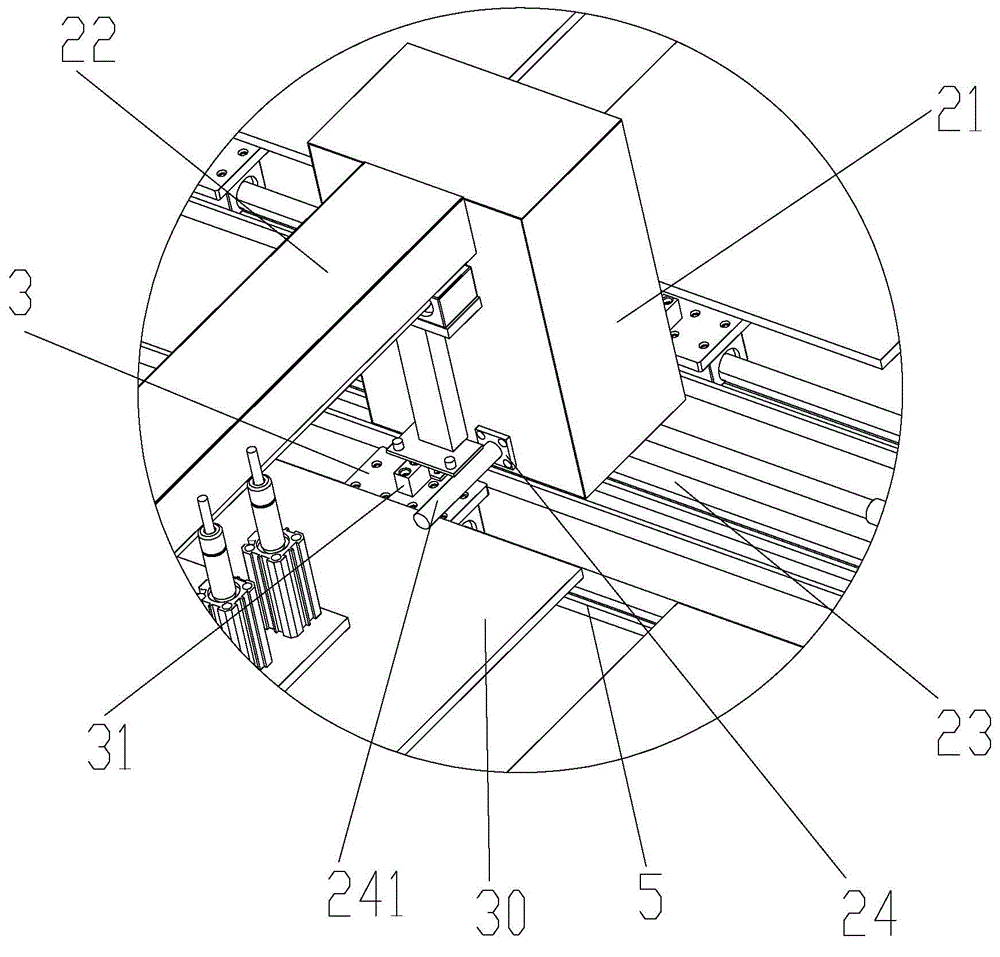

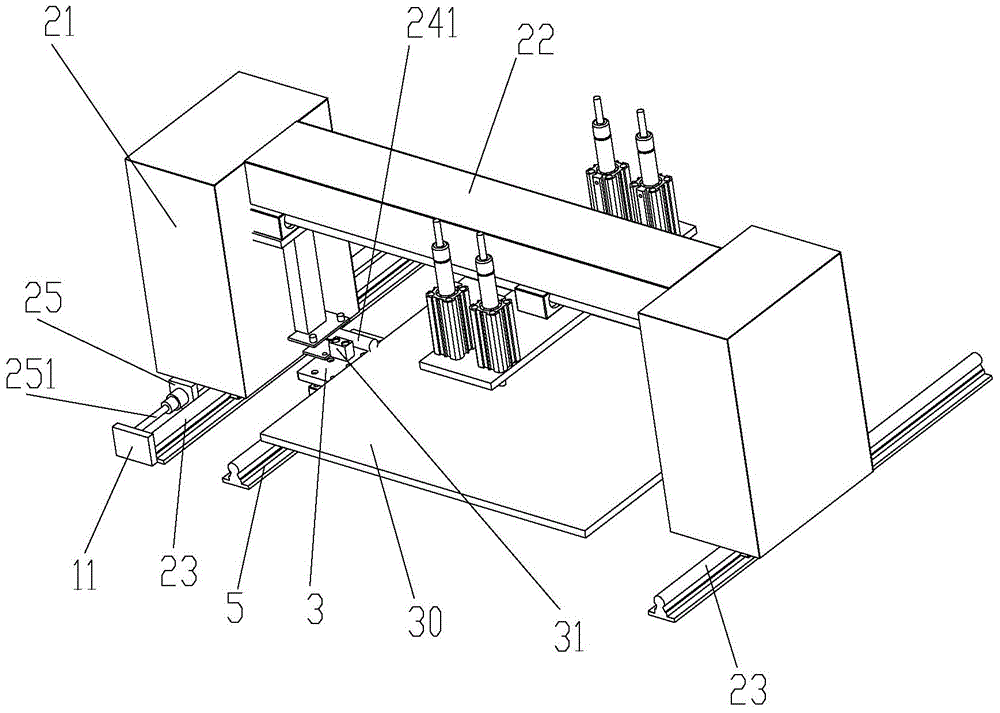

[0017] The present invention first proposes a printing method for an elliptical printing machine in the state of printing platen movement, the method is: the substrate platen and the substrate platen support of the elliptical printing machine continue to run under the drive of the transmission mechanism; When the object table support moves to the predetermined position of the printing station, the print head support and its print head assembly of the printing station run synchronously with the substrate table support, and the print head assembly starts to perform printing actions. When the printing station After the printing is completed, the print head support and its print head assembly stop moving forward and return to the predetermined position; the substrate platen support and the substrate platen continue to move forward, and when they reach t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap