Railroad flat car underframe and method of making the same

A flat car and railway technology, which is applied in the direction of railway car body parts, underframes, freight cars, etc., can solve the problems of fatigue life, stress concentration, beam deformation failure and other problems at the lead welding place, so as to improve fatigue life, improve bearing capacity, and avoid The effect of deformation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The "longitudinal" in the present invention refers to the direction in which the railway flat car extends, that is, the straight direction where the railway flat car runs, and "horizontal" refers to the direction perpendicular to the "longitudinal" in the horizontal plane.

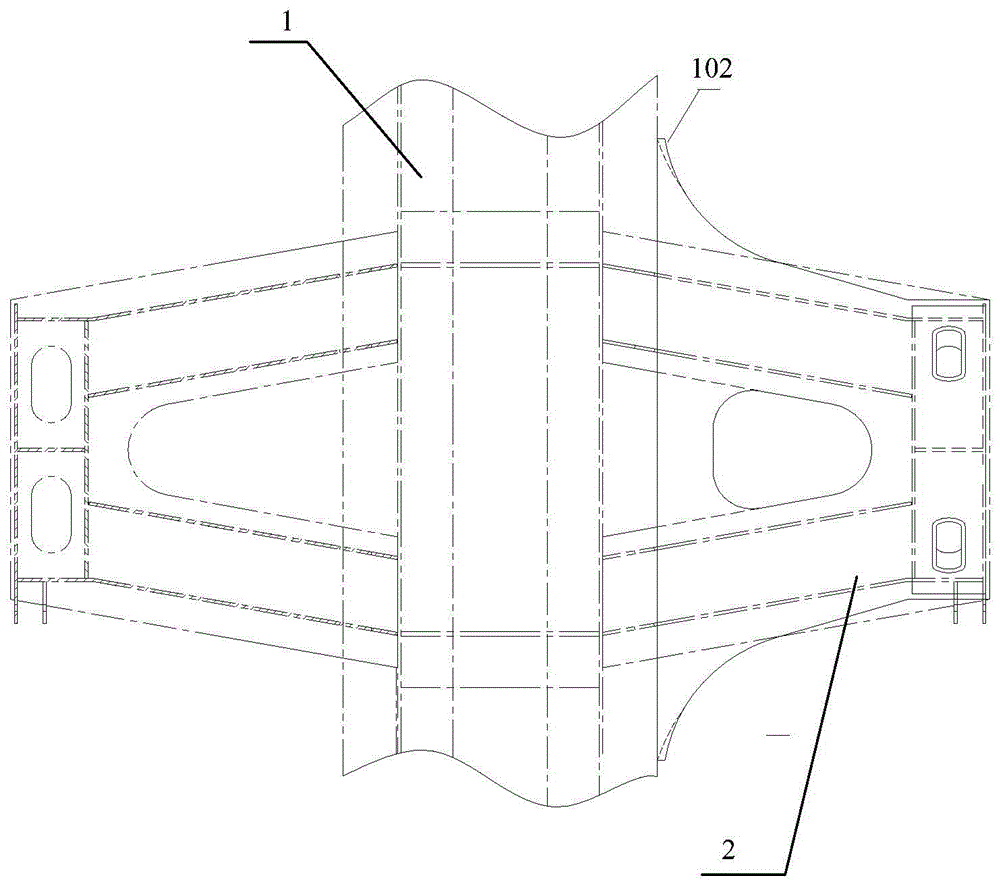

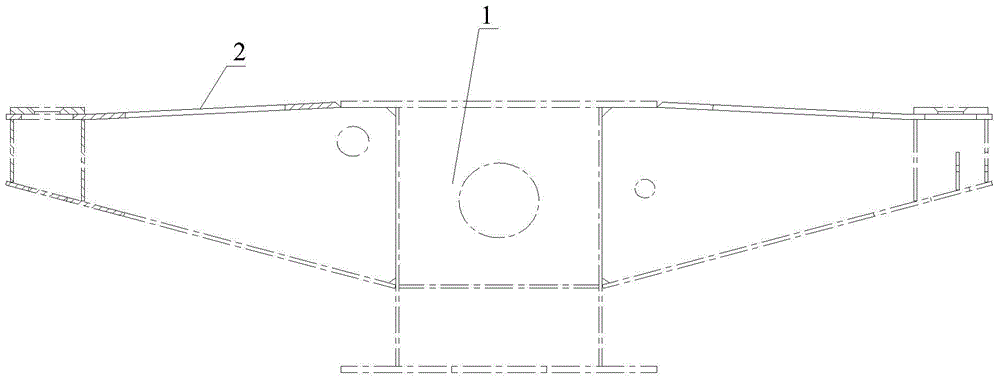

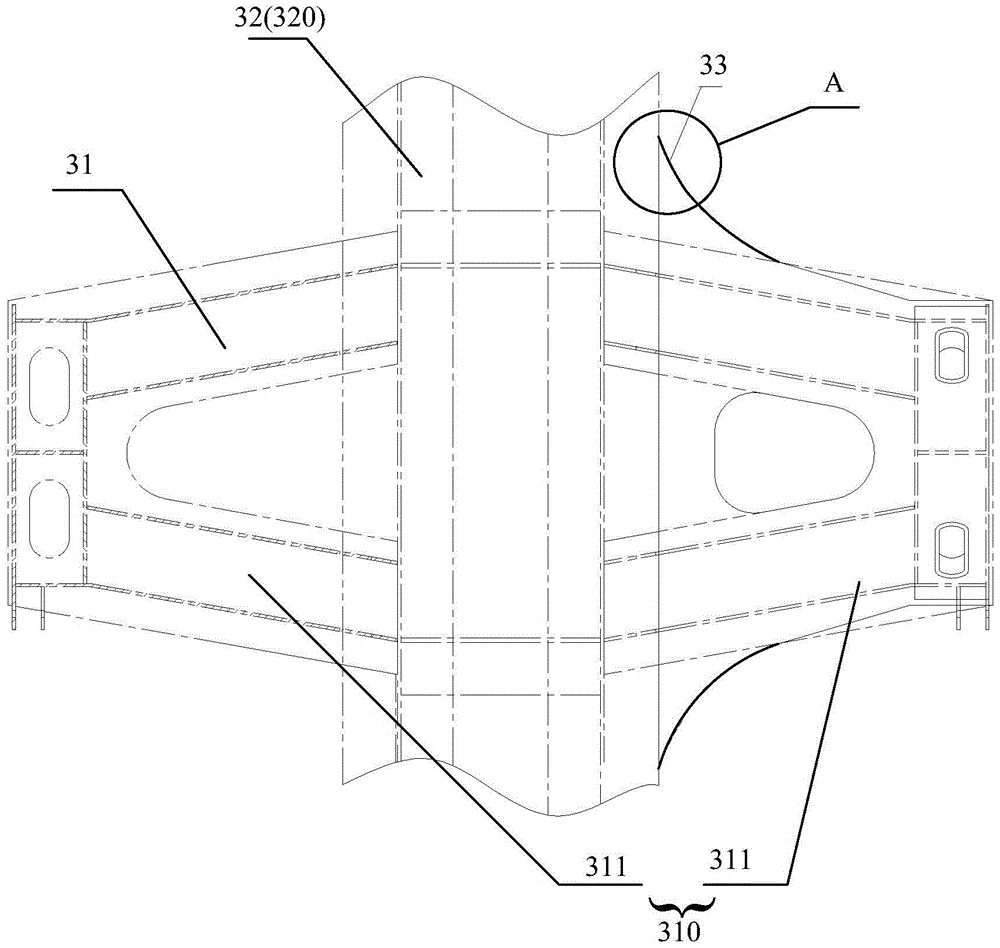

[0020] figure 2 It is the top view of the embodiment of the railway flat car underframe of the present invention; please refer to figure 2 , the present embodiment provides a railway flat car underframe, comprising: a horizontally extending crossbeam 31, and a middle beam 32 extending longitudinally through the crossbeam 31, the crossbeam 31 and the middle beam 32 respectively include a top crossbeam cover plate 310 and a top middle beam cover plate 320, the beam cover plate 310 includes sub-cover plates 311 located on both sides of the center sill cover plate 320, the sub-cover plates 311 are welded and fixed with the center sill cover plate 320, and the front and rear sides of the beam cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com