Method for preparing CaCu3Ti4O12 ceramic material

A ceramic material and ceramic technology, which is applied in the field of electronic ceramic preparation and technical application, can solve the problems of uneven agglomeration and mixing, high reaction temperature, large powder particle size, etc., to avoid local unevenness, short reaction period and gel formation effect of time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

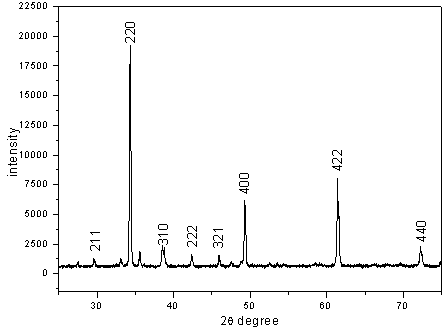

[0030] 1. Nano-CaCu 3 Ti 4 o 12 Powder preparation

[0031] (1) According to CaCu 3 Ti 4 o 12 The stoichiometric ratio of the substance is accurately weighed 10.872g Cu(NO 3 ) 2 ·3H 2 O and 3.5423g Ca(NO 3 ) 2 4H 2 O, add 100mL CH 3 (CH 2 ) 3 OH, reflux at 60°C and stir until completely dissolved to form solution A;

[0032] (2) Mix 20.4mL Ti(OC 4 h 9 ) 4 Slowly drop into solution A, rapidly raise the temperature to 115°C and reflux for 2 hours; then distill off 2 / 3 of the solvent to obtain a brown-green sol, and the distillate is light yellow;

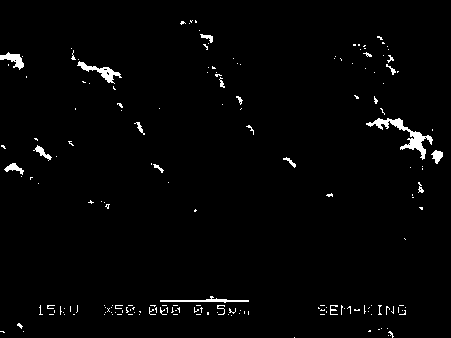

[0033] (3) Dried in a drying oven at 120°C to obtain xerogel, put the xerogel in a muffle furnace and calcined at 800°C for 2 hours, the heating and cooling rate was 4°C / min, and then ground it in an agate mortar to pass 150 mesh Nano-CaCu obtained after sieve 3 Ti 4 o 12 Powder.

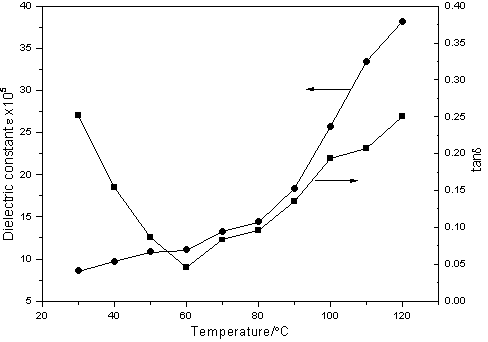

[0034] 2. CaCu 3 Ti 4 o 12 Preparation of Ceramics

[0035] (4) in CaCu 3 Ti 4 o 12 Add polyvinyl alcohol (PVA, PVA accounts f...

Embodiment 2

[0039] (1) According to CaCu 3 Ti 4 o 12 The stoichiometric ratio of the substance is accurately weighed 10.872g Cu(NO 3 ) 2 ·3H 2 O and 3.5423g Ca(NO 3 ) 2 4H 2 O, add 100mL CH 3 (CH 2 ) 3 OH, reflux at 60°C and stir until completely dissolved to form solution A;

[0040] (2) Mix 20.4mL Ti(OC 4 h 9 ) 4 Slowly drop in solution A, rapidly raise the temperature to 115°C and reflux for 1 hour; then distill off 2 / 3 of the solvent to obtain a brown-green sol, and the distillate is light yellow.

[0041] (3) Subsequent processes are all identical to Example 1.

Embodiment 3

[0043] (1) The process of preparing solution A is exactly the same as in Example 1.

[0044] (2) Mix 20.4mL Ti(OC 4 h 9 ) 4 Slowly drop in solution A, rapidly raise the temperature to 110°C and reflux for 2 hours; then distill off 2 / 3 of the solvent to obtain a brown-green sol, and the distillate is light yellow.

[0045] (3) Precursor calcination and preparation of CaCu 3 Ti 4 o 12 Ceramic technology is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com