Method for growth and anneal of zincum-cadmium-tellurium single-crystal, special copple for anneal

A zinc cadmium tellurium and annealing technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of increasing industrial cost and technical difficulty, to avoid local inhomogeneity, reduce crystal growth temperature, and avoid heat concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The best component of Cd is Zn 0.95 Cd 0.05 Taking Te as an example, the specific implementation of the present invention will be further described in detail in conjunction with the accompanying drawings:

[0023] 1. Material synthesis

[0024] According to Zn 0.95 Cd 0.05 The molar ratio to Te is 3:7 and the materials are accurately weighed, and then high-purity (7N) Te, Cd and Zn simple substances are put into a quartz crucible, degassed and evacuated until the vacuum degree is higher than 5×10 -4 Seal the tube at Pa.

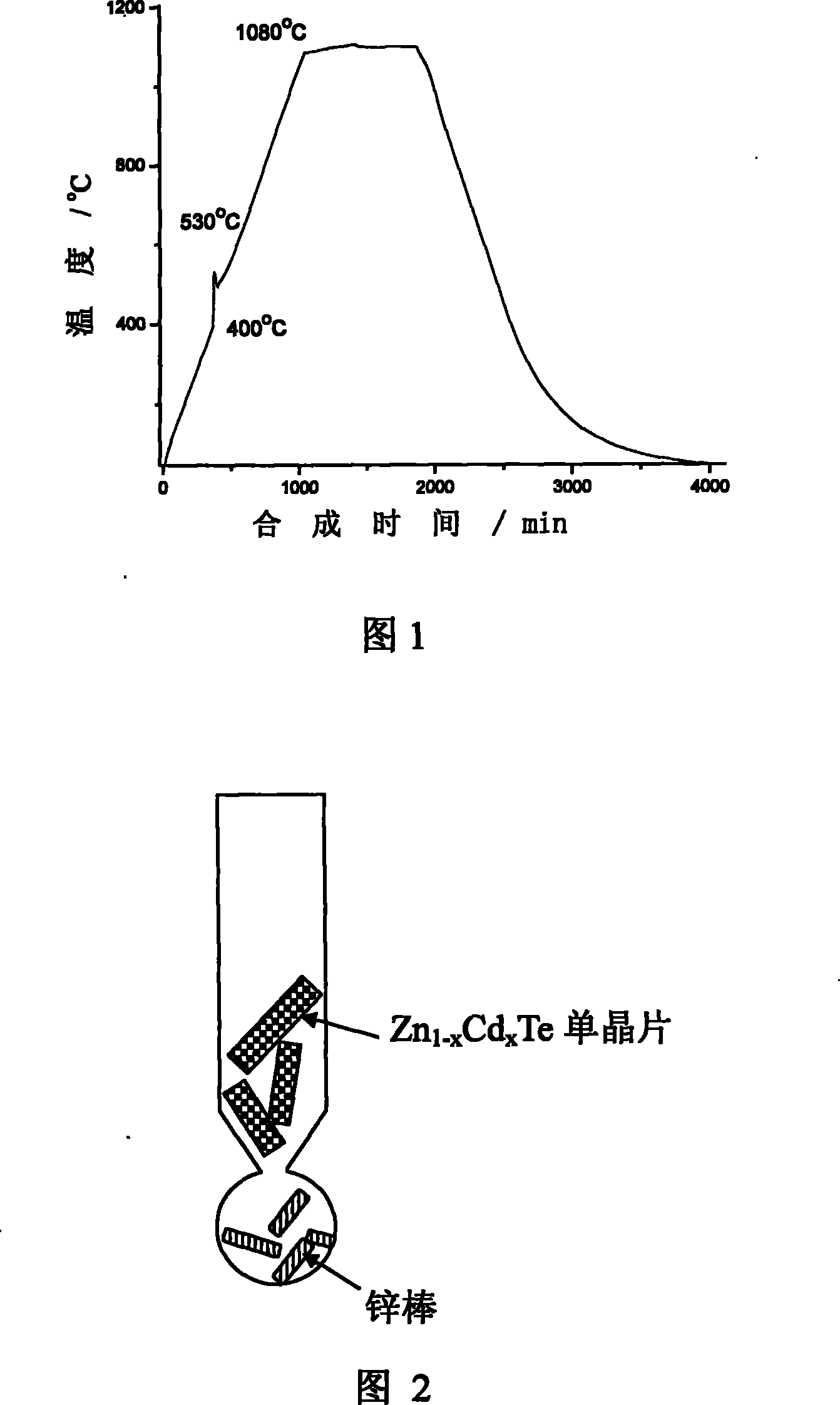

[0025] Put the sealed quartz crucible into a horizontal swing furnace for synthesis, and raise the temperature of the furnace to the synthesis temperature of 1080°C, which is higher than that of Zn 0.95 Cd 0.05 The melting point of Te compound is 20°C. Observing and monitoring the furnace temperature instrument, it is found that when the furnace temperature rises to 400°C-530°C, there will be a severe exothermic peak, and the heat generated will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com