Low-temperature resistant fluororubber for oil seal

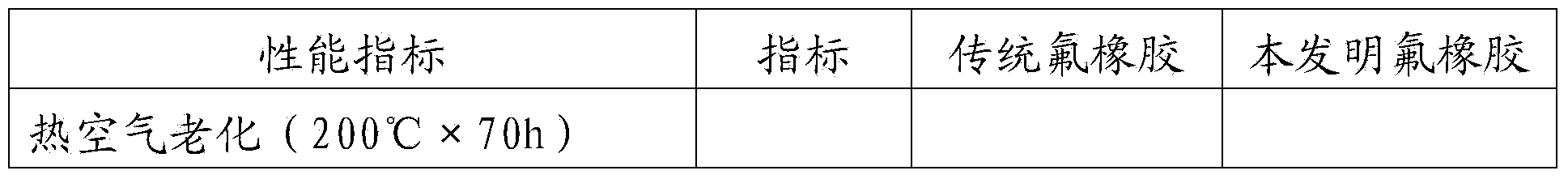

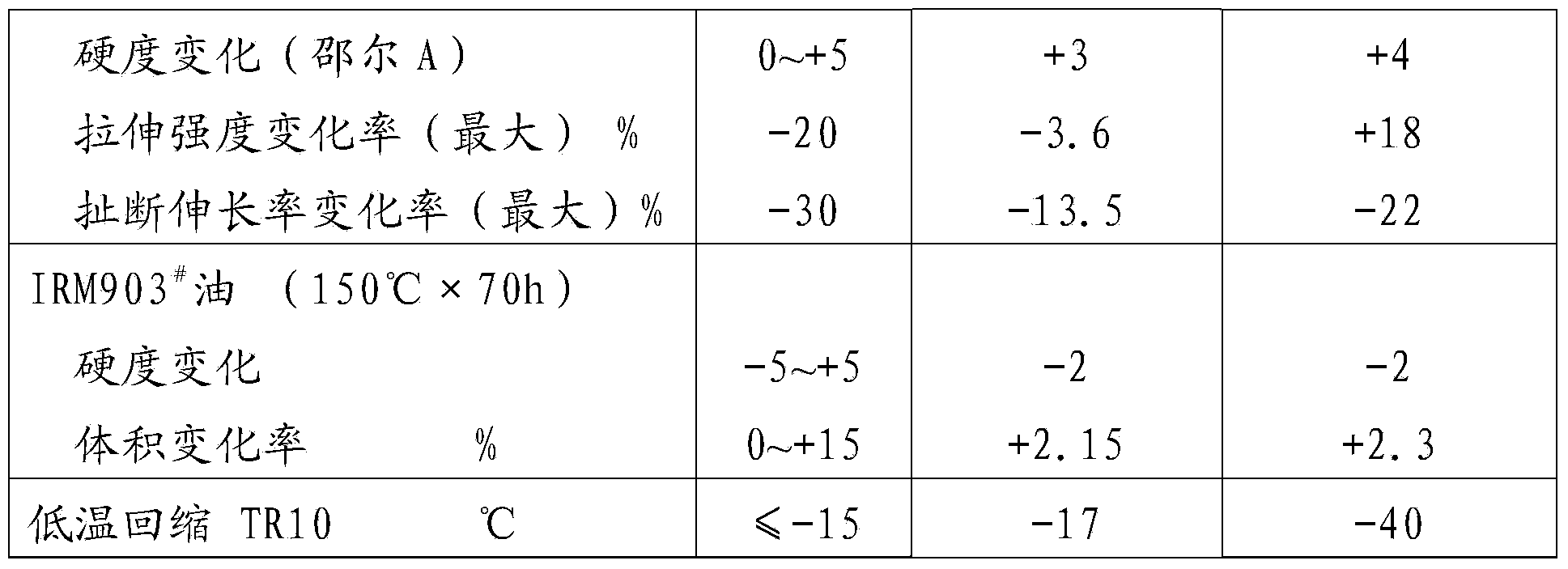

A technology of fluorine rubber and low temperature resistance, which is applied in the field of rubber. It can solve the problems of fluorine rubber, such as loss of elasticity, poor low temperature resistance, and failure to meet the shock absorber's start-up without oil leakage, and achieve good oil resistance and wide temperature range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A fluororubber for low temperature resistant oil seal, its components include 30kg VPL85540, 70kg LTFE6400, 1.0kg HT290, 35kg10WC10222, 15kg N990, 3.0kg TAIC-70 and 1.2kg Shuangerwu-45.

Embodiment 2

[0019] A fluororubber for low temperature resistant oil seal, its components include 50kg VPL85540, 50kg LTFE6400, 1.2kg HT290, 30kg10WC10222, 10kg N990, 5kg N774, 3.2kg TAIC-70 and 1.5kg Shuangerwu-45.

Embodiment 3

[0021] A fluororubber for low temperature resistant oil seal, its components include 70kg VPL85540, 30kg LTFE6400, 1.5kg HT290, 10kg10WC10222, 30kg N990, 5kg N774, 3.5kg TAIC-70 and 1.8kg Shuang25-45.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com