Polyhydroxyalkanoate composite material and preparation method thereof

A polyhydroxyalkanoate and composite material technology, applied in the field of polymer materials, can solve the problems of lack of elasticity of composite materials, deterioration of composite material properties, easy occurrence of agglomeration, etc., and achieves simple preparation method, improved elasticity and strength, and low cost. degradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

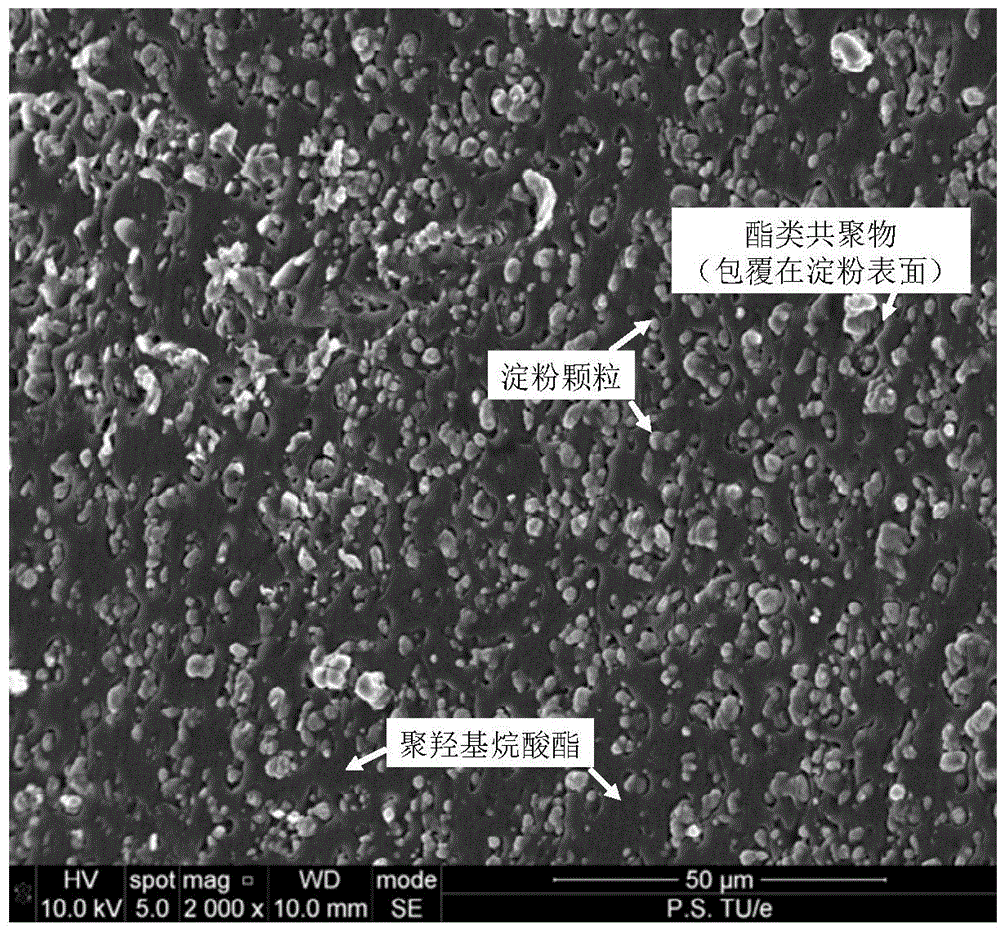

[0022] 50kg of ethylene-vinyl acetate copolymer, 50kg of gelatinized potato starch, 10kg of glycerol, 1kg of maleic anhydride and 0.1kg of dibenzoyl peroxide were uniformly premixed with vinyl acetate mass percentage content of 50%, Reactive blending extrusion granulation was carried out through a twin-screw extruder at 135° C. to obtain a granulated blend, wherein the rotational speed of the screws was 50 rpm.

[0023] 100 kg of 3-hydroxybutyrate-3-hydroxyhexanoate copolymer (3-hydroxyhexanoate molar content is 11%) and the granulated blend are blended and extruded through a twin-screw extruder at 150°C Pelletize to obtain a polyhydroxyalkanoate composite material, wherein the screw speed is 120 rpm.

[0024] Put the polyhydroxyalkanoate composite material into the mold, and first hot-press on a flat vulcanizer (hot-press temperature 160°C, hot-press time 3min, hot-press pressure 10MPa), and then cold-press (cold-press time 10min, cold-press Pressure 10MPa), made into a shee...

Embodiment 2

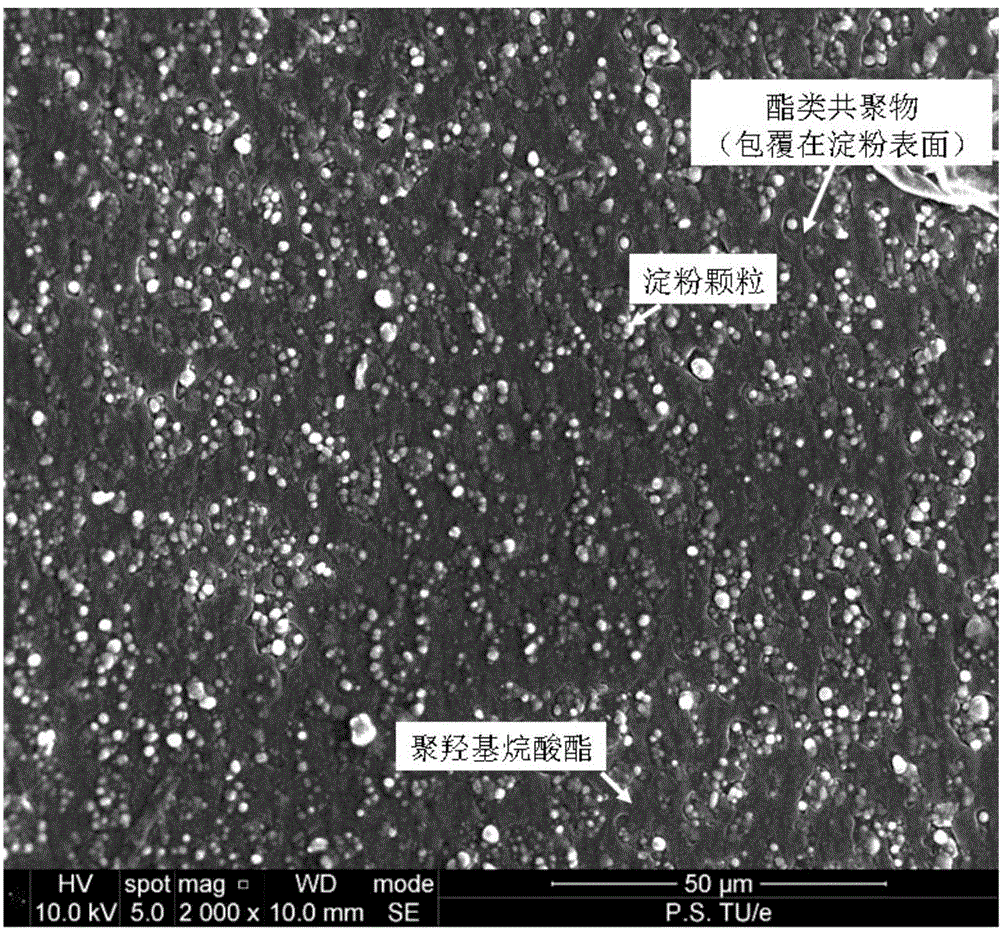

[0026] Butylene terephthalate mass percentage content is 40% butylene adipate-butylene terephthalate copolymer 70kg, thermoplastic tapioca starch 40kg, glycerol 15kg, maleic anhydride 1.5 kg and 0.15 kg of dicumyl peroxide were premixed evenly, and reactively blended and extruded to obtain granulated blends in a screw extruder, wherein the screw speed was 60 rpm, and the blending temperature was 165°C.

[0027] 110kg of 3-hydroxybutyrate-4-hydroxybutyrate copolymer (4-hydroxyhexanoate molar content is 28%) and the granulated blend were blended and extruded through a twin-screw extruder at 155°C Pelletize to obtain a polyhydroxyalkanoate composite material, wherein the screw speed is 110 rpm.

[0028] Put the polyhydroxyalkanoate composite material into the mold, and first hot-press on a flat vulcanizer (hot-press temperature 160°C, hot-press time 3min, hot-press pressure 10MPa), and then cold-press (cold-press time 10min, cold-press Pressure 10MPa), made into a sheet with a t...

Embodiment 3

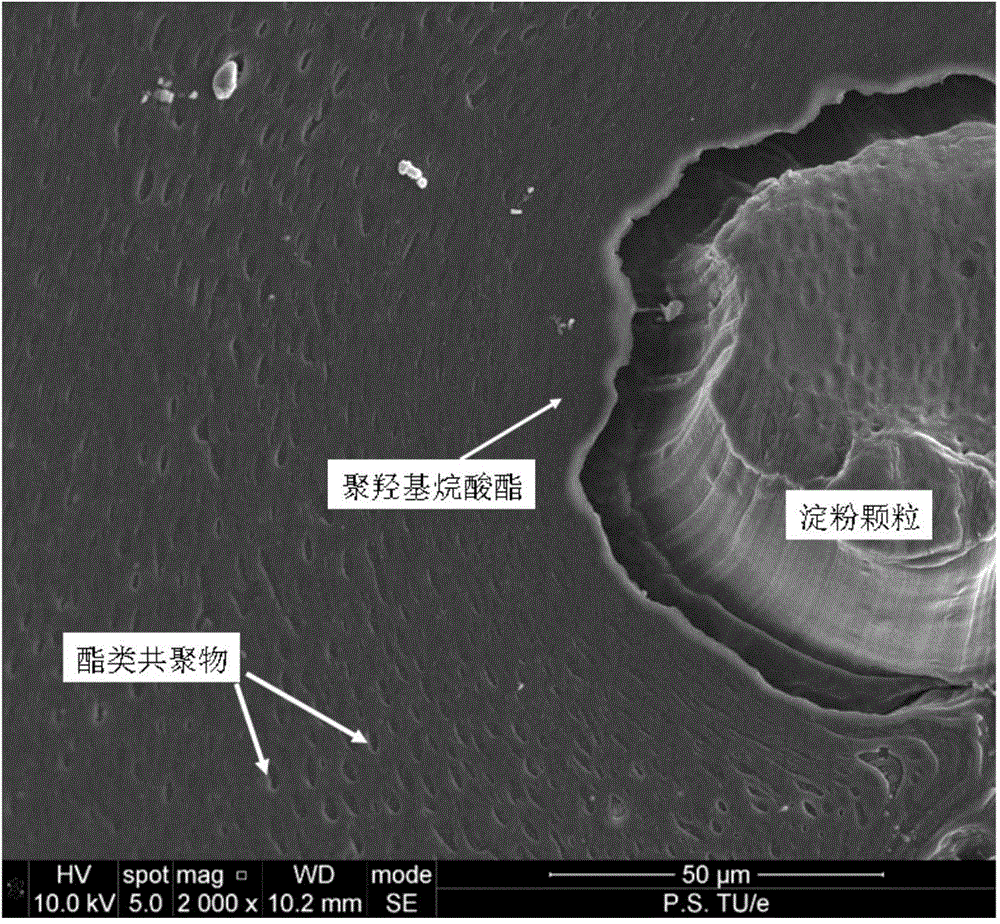

[0030] Butylene adipate mass percentage composition is 50% butylene succinate-butylene adipate copolymer 75kg, potato starch 45kg, ethylene glycol 13kg, itaconic anhydride 1kg and over After 0.08 kg of tert-butyl oxidized benzoate was premixed uniformly, reactive blending and extrusion granulation was carried out by a twin-screw extruder at 160° C. to obtain a granulated blend, wherein the screw speed was 70 rpm.

[0031] 108kg of 3-hydroxybutyrate-4-hydroxybutyrate copolymer (4-hydroxybutyrate molar content is 20%) and the granulated blend were blended and extruded through a twin-screw extruder at 160°C Pelletize to obtain a polyhydroxyalkanoate composite material, wherein the screw speed is 105 rpm.

[0032] Put the polyhydroxyalkanoate composite material into the mold, and first hot-press on a flat vulcanizer (hot-press temperature 160°C, hot-press time 3min, hot-press pressure 10MPa), and then cold-press (cold-press time 10min, cold-press Pressure 10MPa), made into a shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com