Basement bottom plate dewatering well mouth plugging casing and construction method

A technology of basement floor and construction method, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., and can solve problems such as plugging failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

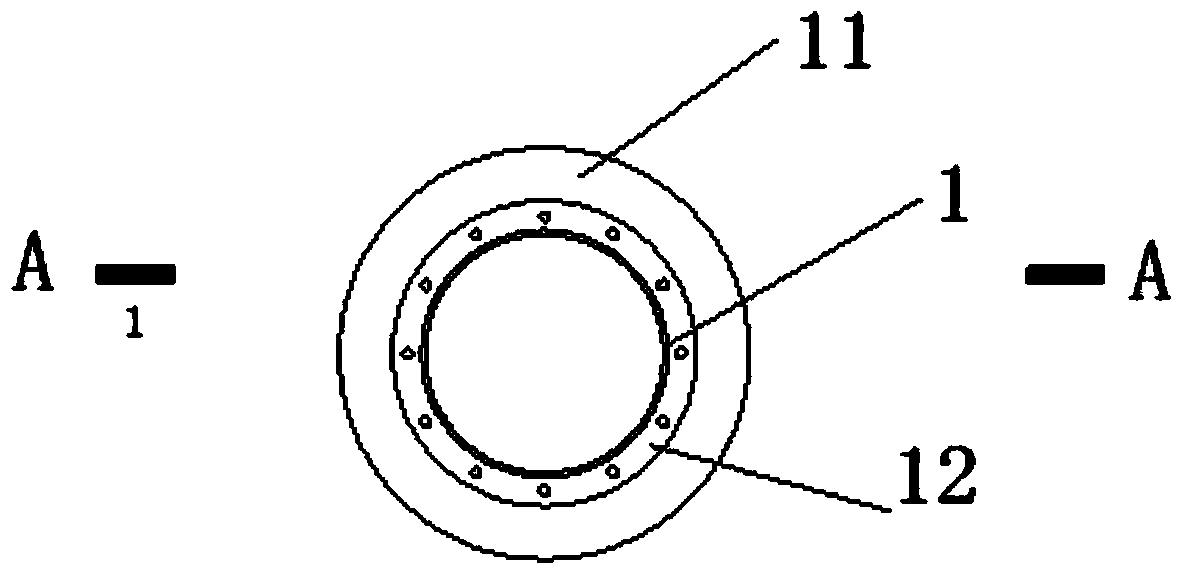

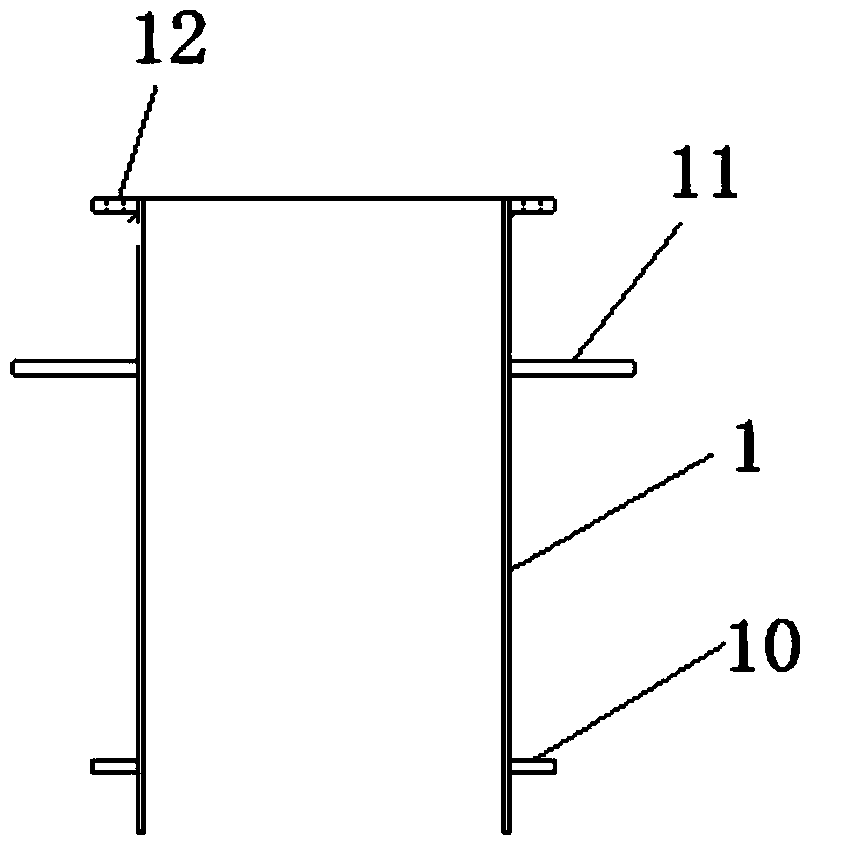

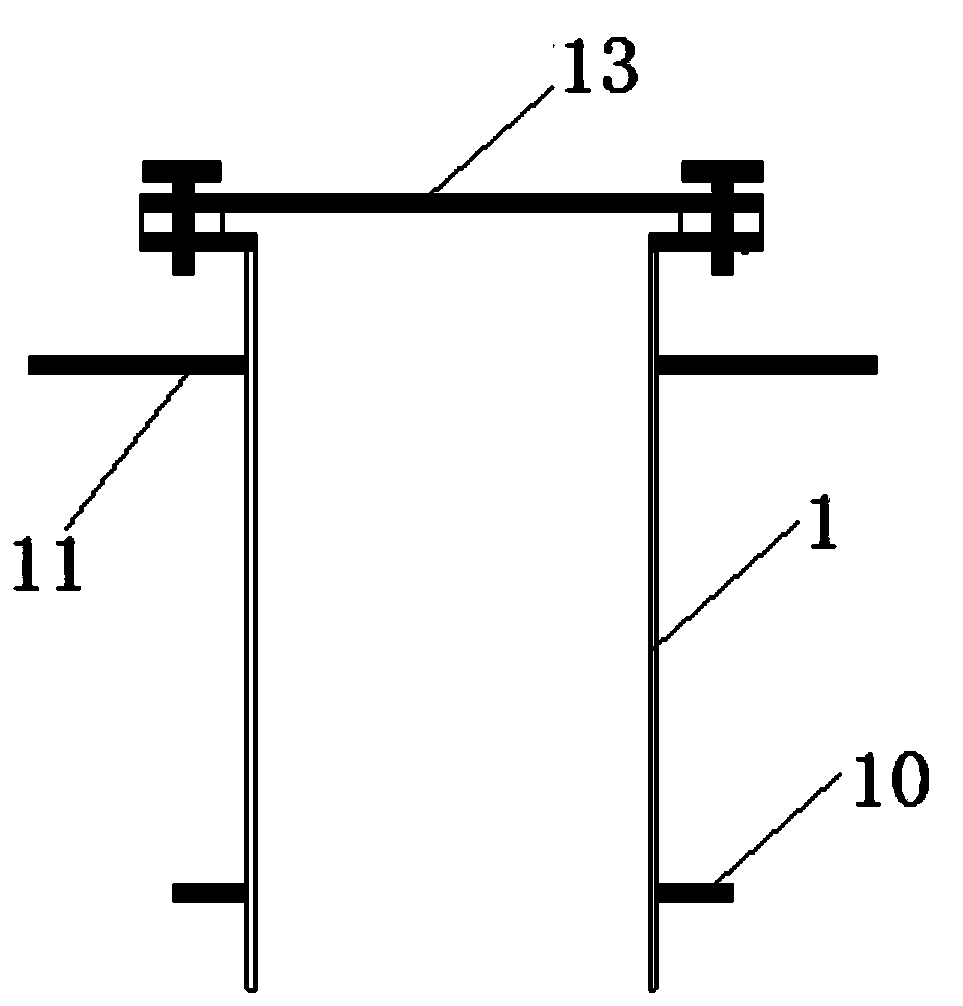

[0028] Combine below Figure 1 to Figure 3 The specific structure of the wellhead plugging casing of the dewatering well on the basement floor is explained, which includes a vertically arranged steel pipe 1, a stabilizing ring 10 welded on the outer circumference of the bottom of the steel pipe, and a water-stop ring 11 welded on the outer circumference of the upper part of the steel pipe A flange 12 is welded on the outer circumference of the upper mouth of the steel pipe, a cover plate 13 is provided on the flange, and a rubber gasket is provided between the flange and the cover. When the groundwater level is high, use a cover plate with a rubber gasket to seal the dead waterway, so that the bottom plate concrete can be poured in a dry place, and the construction quality can be guaranteed. The maximum water pressure can be controlled at 5kg / cm2. During the slow hardening stage of the concrete , to ensure that groundwater does not penetrate the concrete and form small cracks ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com