Water supply equipment integrating vacuum inhibition and reverse flow compensation

A technology of water supply equipment and vacuum suppressor, which is applied in the configuration of water supply main pipeline, water supply pipeline system and water supply pool, etc., can solve the problems of internal pollution and external pollution of the steady flow tank, and achieve the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

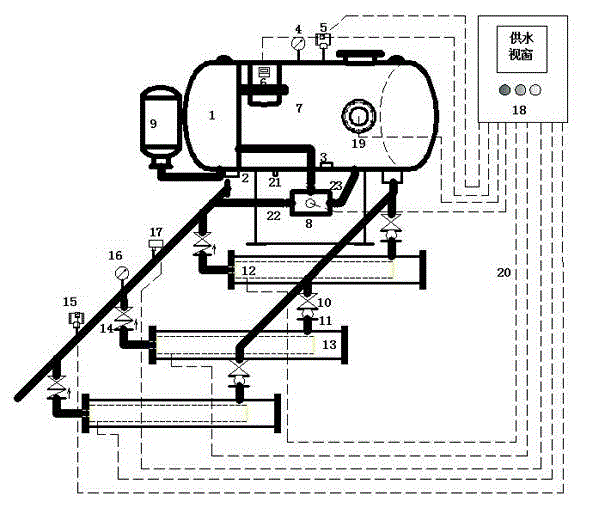

[0014] Such as figure 1 As shown, the present invention mainly includes: a pre-compression chamber 1, a pre-compression self-balancing device 2, a liquid level controller 3, a negative pressure gauge 4, a pressure transmitter 5, a vacuum suppressor 6, a steady flow compensation tank 7, a countercurrent compensation Device 8, voltage stabilizing accumulator 9, valve 10, flexible rubber joint 11, water pump 12, shielded type stabilizing sleeve 13, water outlet valve 14, pressure transmitter 15, pressure gauge 16, overpressure protection device 17, Frequency conversion control cabinet 18, disinfection device 19, wire 20, cleaning and blowdown valve 21, small flow pressure maintaining pipe 22, countercurrent compensation pipe 23, valve 24.

[0015] Among them, the steady flow tank is composed of two chambers, which are divided into a pre-pressure chamber 1 and a steady-flow compensation tank 7 , and a pre-pressure self-balancing device 2 is installed at the lower part of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com